Poly lithium battery structure with high capacity and high output ratio power

A technology with high output and specific power, applied in the direction of secondary batteries, structural parts, battery pack parts, etc., can solve the problems of battery cycle performance deterioration, current density asymmetry, internal resistance increase, etc., to improve the polarization effect Accumulation of thermal effects, reduction of battery polarization effects, and improvement of thermal runaway platforms

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] combine Figure 7 to Figure 16 , the preferred embodiments of the present invention will be described in further detail.

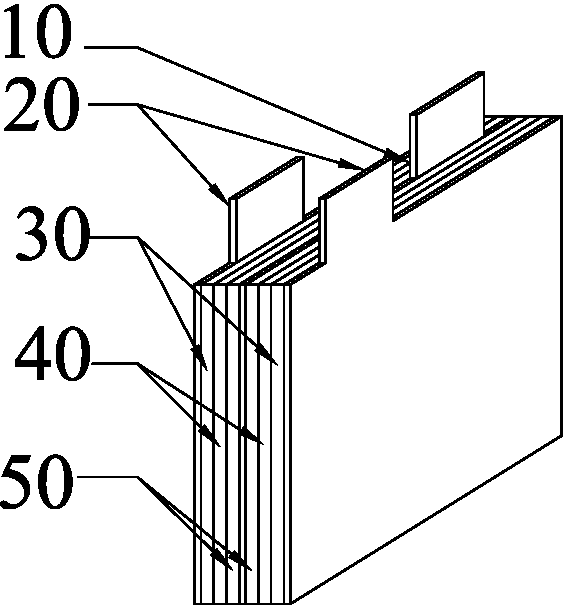

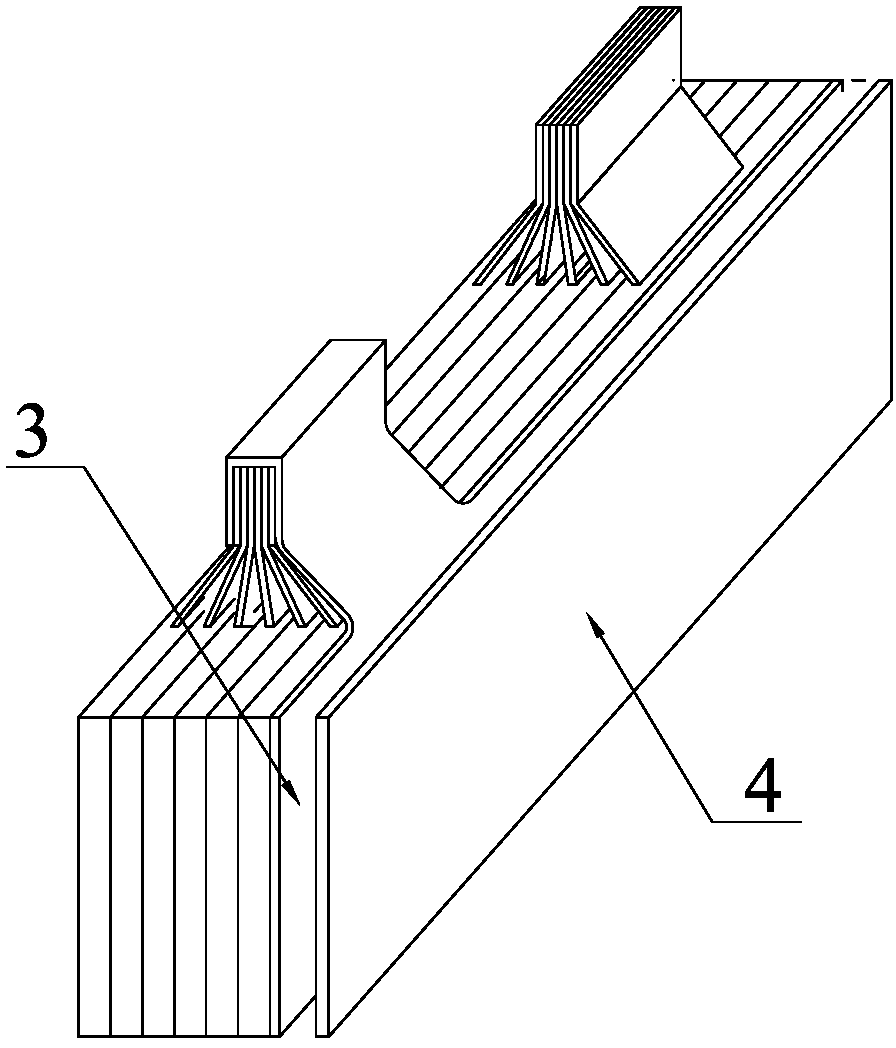

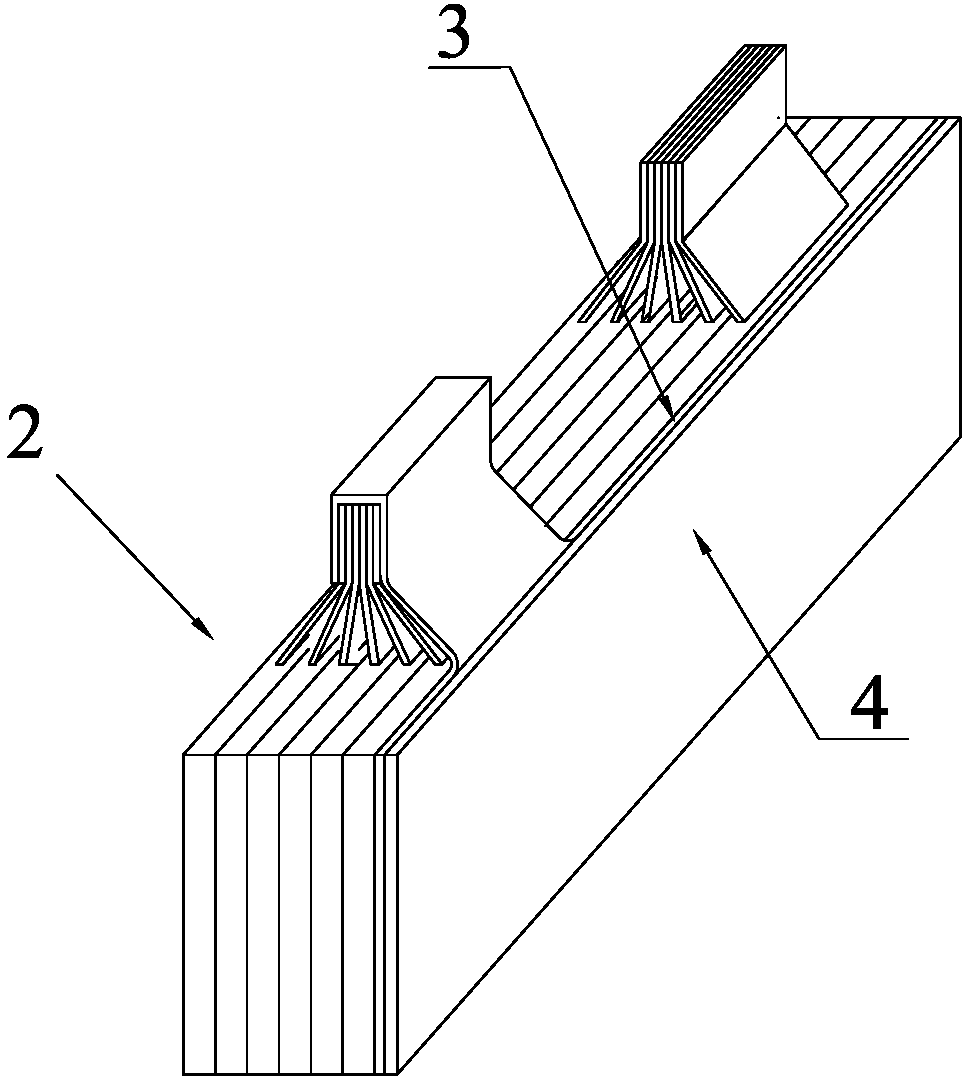

[0043] A large-capacity, high-output specific power polylithium battery structure includes at least two such as Figure 7 The monolithic group 2 formed by the monolithic battery pole piece 1 is shown.

[0044] The internal structure of the single-piece battery pole piece 1 is the same as that of the single-piece battery pole piece in the traditional polymer lithium-ion battery pack, and they are neatly stacked in order. The positive pole tab 11 and the negative pole tab on each single-piece battery pole piece 1 12 all correspond neatly.

[0045] In a monolithic group 2, the positive electrode tab 11 and the negative electrode tab 12 are respectively pressed and shaped, such as Figure 8shown. Due to the grouping form, the number of stacked pole pieces is small, the thickness is small, and the deformation of the tabs of the edge pole pieces is sm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com