Template-based three-dimensional network carbon material/macromolecule functional composite and preparation method thereof

A functional composite material and three-dimensional network technology, which is applied in the processing technology and application field of polymer functional composite materials, can solve the problems of poor stability, high cost, and low preparation efficiency, and achieve low cost, enhanced flexibility, and simple preparation methods Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

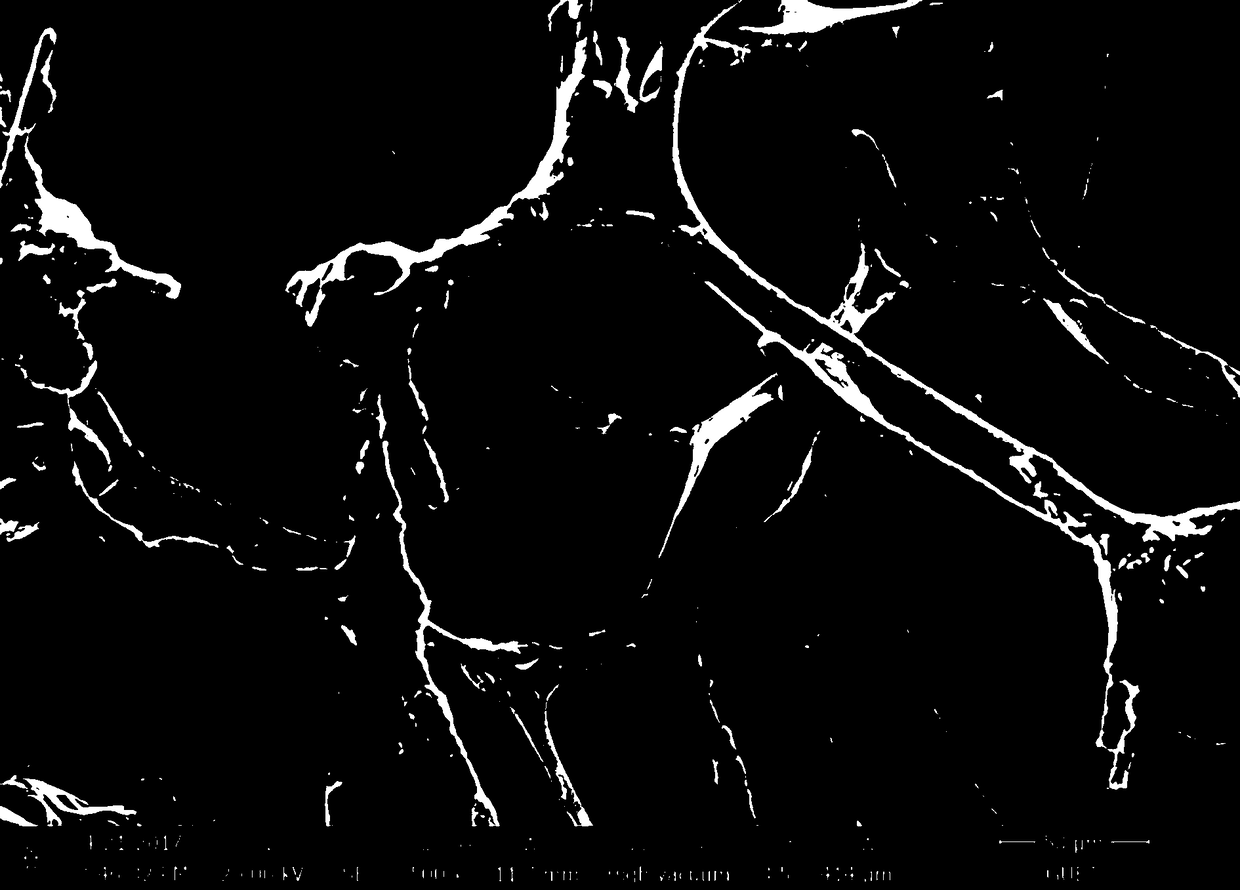

[0032] (1) Using graphene oxide as a raw material, disperse it in water to form a uniform graphene oxide aqueous solution with a concentration of 1 mg / mL;

[0033] (2) Immerse the polyurethane sponge in the graphene oxide aqueous solution of step (1) for 1 min, adjust the pH of the system to 9-10, add the reducing agent sodium borohydride, wherein the mass ratio of sodium borohydride to graphene oxide is 6:1, Put them together into the reaction container, reduce the reaction in an oven at 100°C for 2 hours, and finally take it out and dry to obtain three-dimensional graphene with polyurethane sponge as the template;

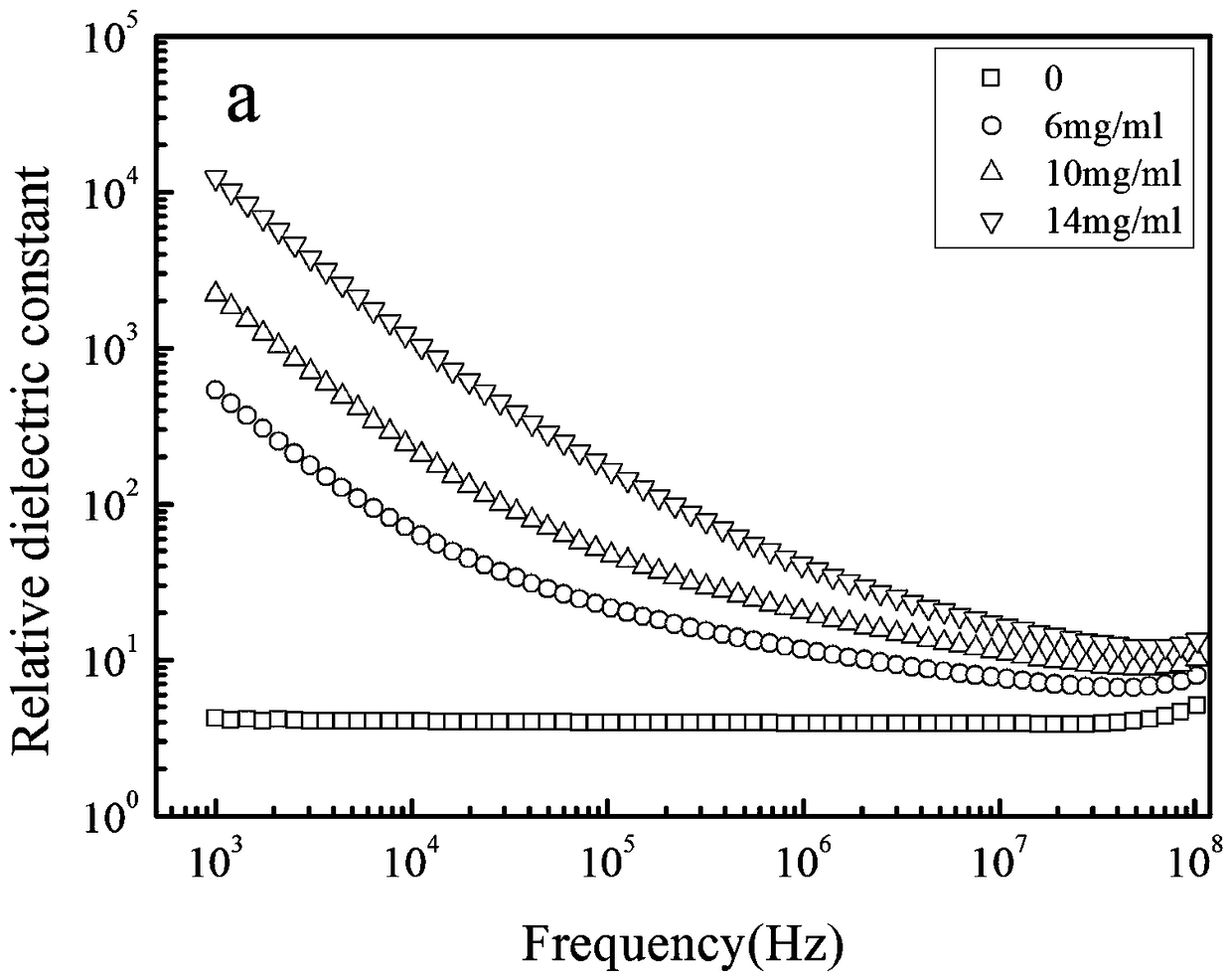

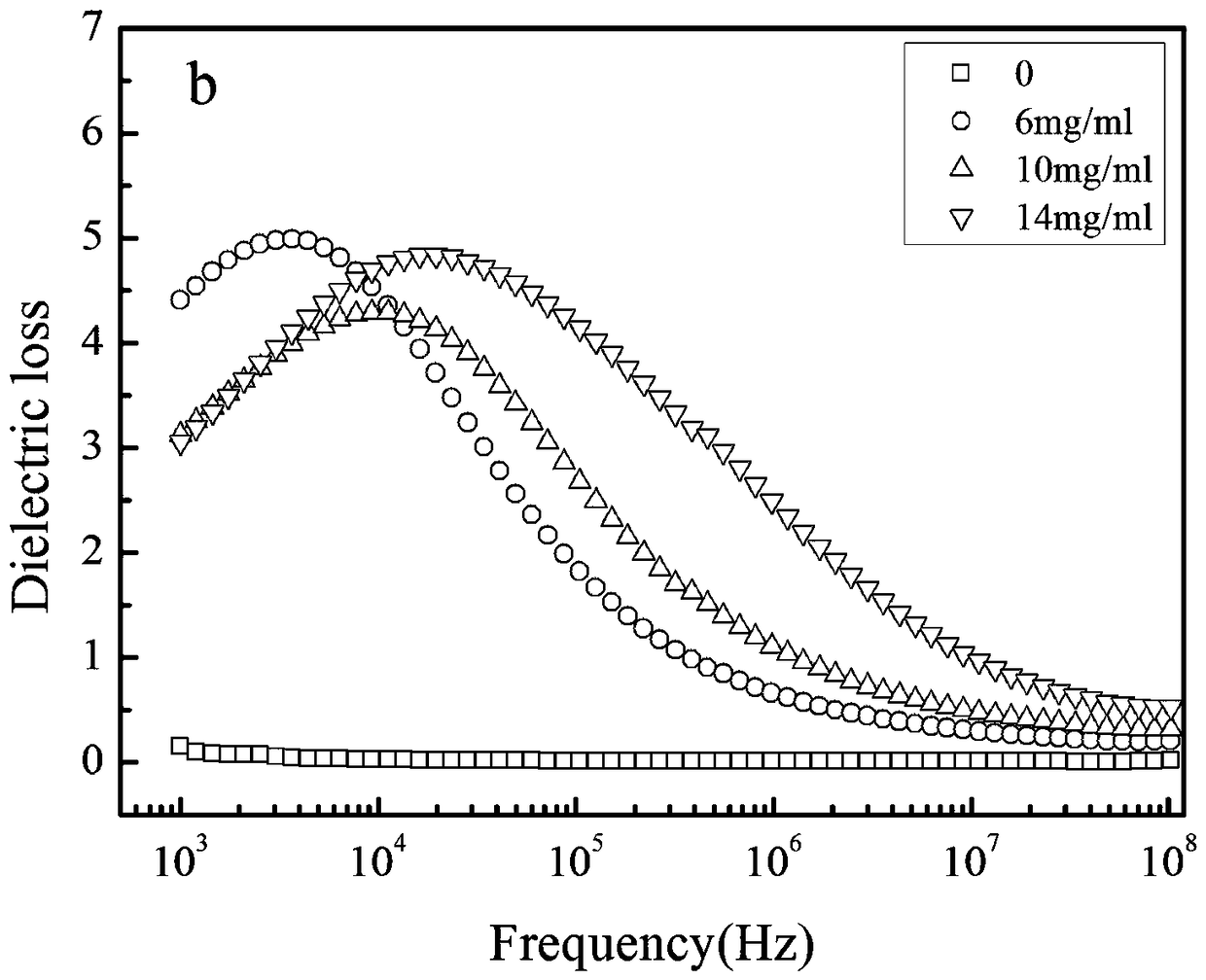

[0034] (3) For the three-dimensional graphene impregnated with polyurethane sponge as a template, the silicone resin of type 1151 was added, and 1wt% curing agent of the silicone resin was added before impregnation, and mixed with the silicone resin evenly. Then cured at room temperature for 12h to obtain a dielectric constant of 1.01×10 4 The three-dimensional ...

Embodiment 2

[0036] (1) Using conductive carbon black as a raw material, disperse it in water to form a uniform conductive carbon black aqueous solution with a concentration of 20 mg / mL;

[0037] (2) Immerse the melamine sponge in the conductive carbon black aqueous solution of step (1) for 20 minutes, adjust the pH of the system to 9-10, and add the reducing agent sodium borohydride, wherein the mass ratio of sodium borohydride to conductive carbon black is 10:1 , and put them into a reaction container together, and reduce them in an oven at 90°C for 4 hours, and finally take them out and dry them to obtain a three-dimensional conductive carbon black with melamine sponge as a template;

[0038] (3) E103 epoxy resin was cast on the three-dimensional conductive carbon black with melamine sponge as the template. Before pouring, 30wt% curing agent of epoxy resin was added and mixed evenly, and then cured at 35°C for 3 hours. Then cured at 80°C for 12 hours, and finally obtained a dielectric c...

Embodiment 3

[0040] (1) Using carbon nanotubes as raw materials, disperse them in water to form a uniform carbon nanotube aqueous solution with a concentration of 14mg / mL;

[0041] (2) Immerse the polyurea sponge in the carbon nanotube aqueous solution of step (1) for 40 minutes, adjust the pH of the system to 9-10, and add the reducing agent lithium borohydride, wherein the mass ratio of lithium borohydride to carbon nanotubes is 8:1 , and put them together into a reaction container, and reduce them in an oven at 80°C for 3 hours, and finally take them out and dry them to obtain three-dimensional carbon nanotubes with polyurea sponge as a template;

[0042] (3) For the three-dimensional carbon nanotubes with polyurea-formaldehyde sponge as the template, the unsaturated resin of model 191 is poured, in which, 1wt%-3wt% accelerator of unsaturated resin is added before pouring, and then 2wt% curing agent is added after stirring Mix evenly, and finally cure at room temperature for 10 hours to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| relative permittivity | aaaaa | aaaaa |

| relative permittivity | aaaaa | aaaaa |

| relative permittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com