Tea leaf screening device for agricultural production

A screening device and tea technology, applied in the direction of screening, solid separation, grid, etc., can solve the problems of low screening efficiency, slow screening speed, large labor consumption, etc., and achieve improved screening rate, good screening, and uniform dispersion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

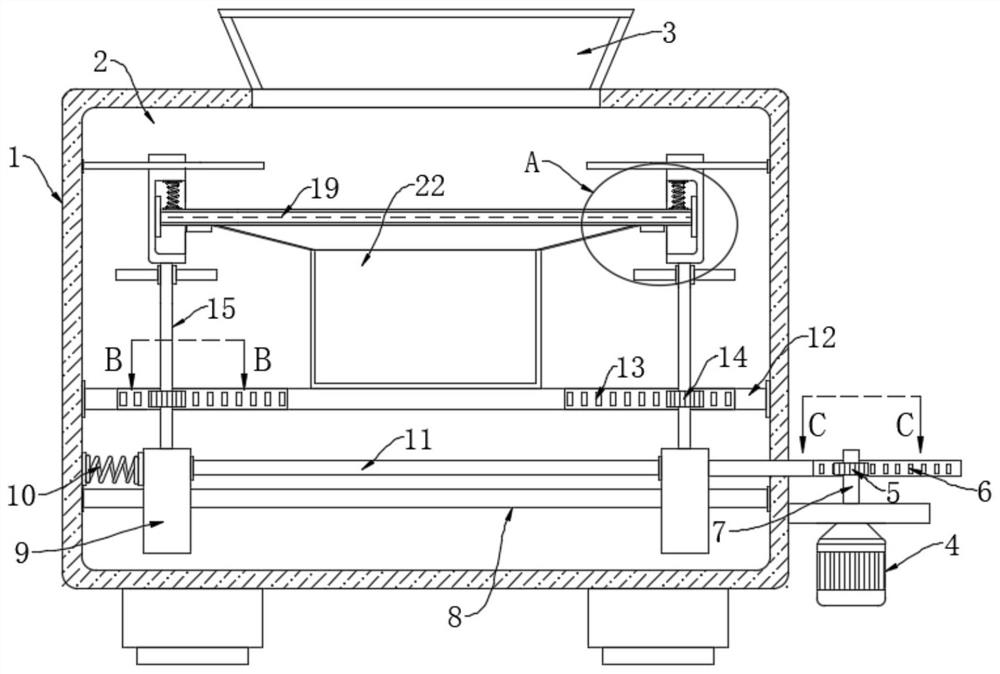

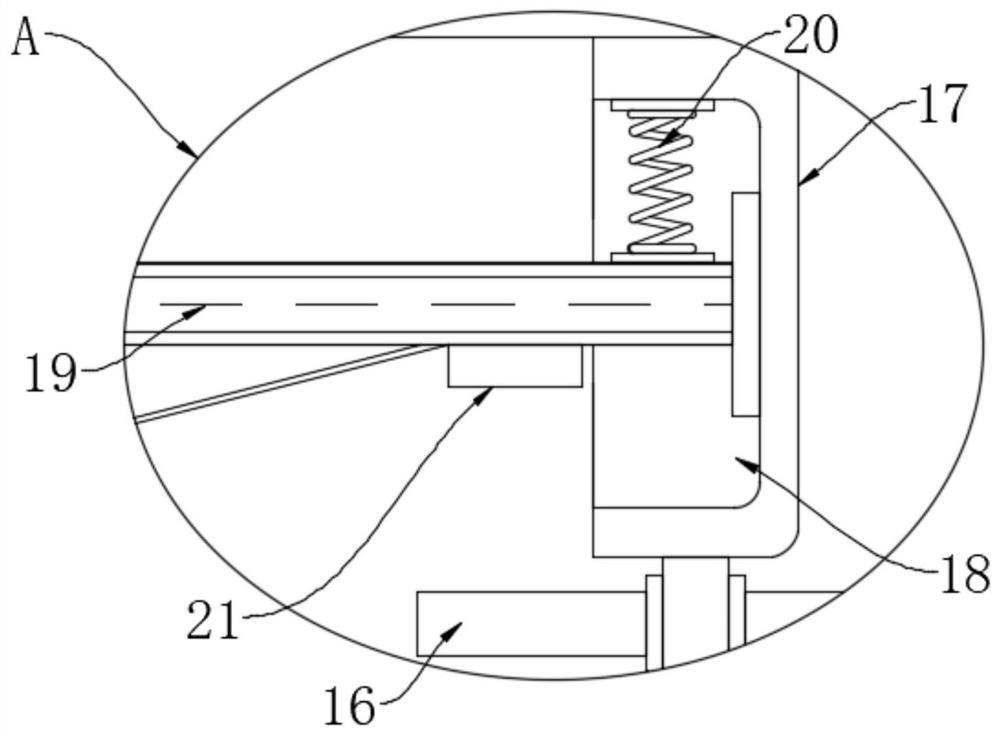

[0024] refer to Figure 1-4 , a tea screening device for agricultural production, comprising a housing 1, one end of the housing 1 is fixedly connected to a support frame, which is convenient for moving the housing 1 and cleaning the space below the housing 1, and a screening chamber is provided in the housing 1 2. It is used to screen the tea leaves. The inner top of the screening chamber 2 communicates with the outside world through the feed hopper 3, so that the tea leaves can better enter the screening chamber 2 and prevent the tea leaves from falling to the upper end of the casing 1;

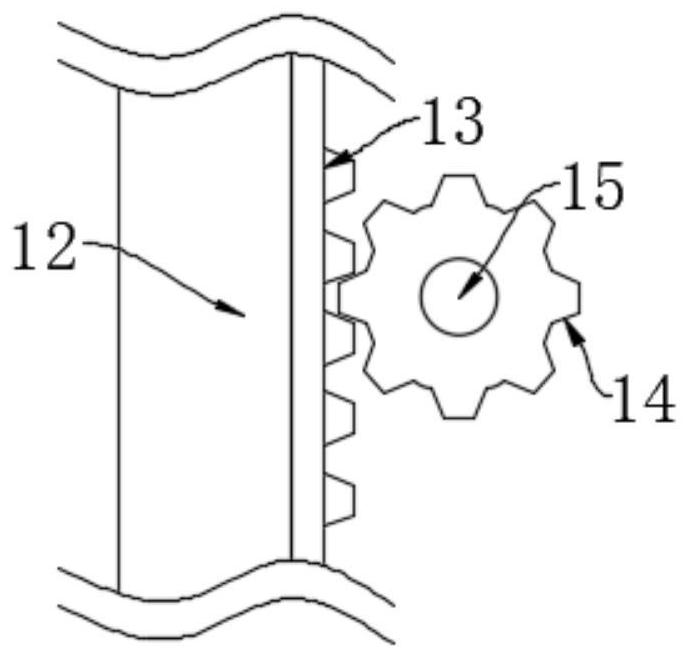

[0025] Trigger mechanism. The trigger mechanism is used to start the whole device. The trigger mechanism includes a motor 4 installed on one side of the housing 1. The motor 4 needs to be installed on the mounting frame during installation. The end of the output shaft of the motor 4 is fixedly connected to the first rotating rod 7 (the end of the output shaft runs through the mounting frame...

Embodiment 2

[0031] refer to Figure 5-6 The difference between this embodiment and Embodiment 1 is that the opposite sides of the two installation blocks 17 are fixedly connected with the inner wall of the screening chamber 2 through the air bag 27, and the two air bags 27 are all communicated with the outside world through the air inlet pipe 23, To facilitate external air suction into the air bag 27, blowing plates 24 are installed on opposite sides of the two installation blocks 17, and the lower ends of the two blowing plates 24 are fixedly connected with the upper end of the filter screen 19, and the two blowing plates 24 is provided with a ventilation chamber 25, and the two ventilation chambers 25 communicate with the corresponding air bag 27 through the air outlet pipe 26. 23 and the two outlet pipes 26 are equipped with check valves, which are convenient to control the one-way flow of gas. The opposite sides of the two vent chambers 25 are provided with a plurality of blowing port...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com