Blenders

a technology of cleaning brushes and cleaning brushes, applied in the field of cleaning brushes, can solve the problems of low bulk density materials, blenders are often in somewhat inaccessible and elevated locations, cleaning can present a safety hazard to workers,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

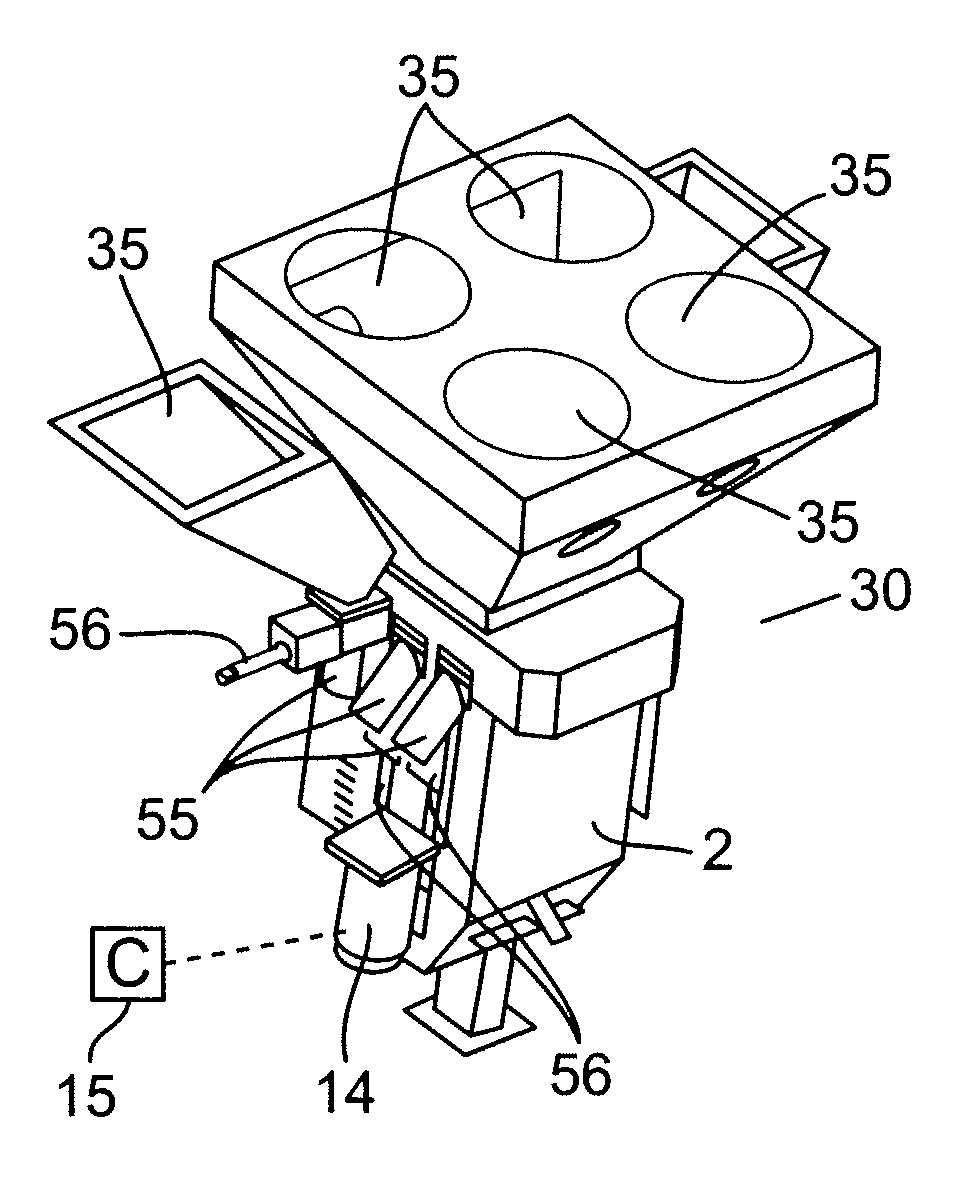

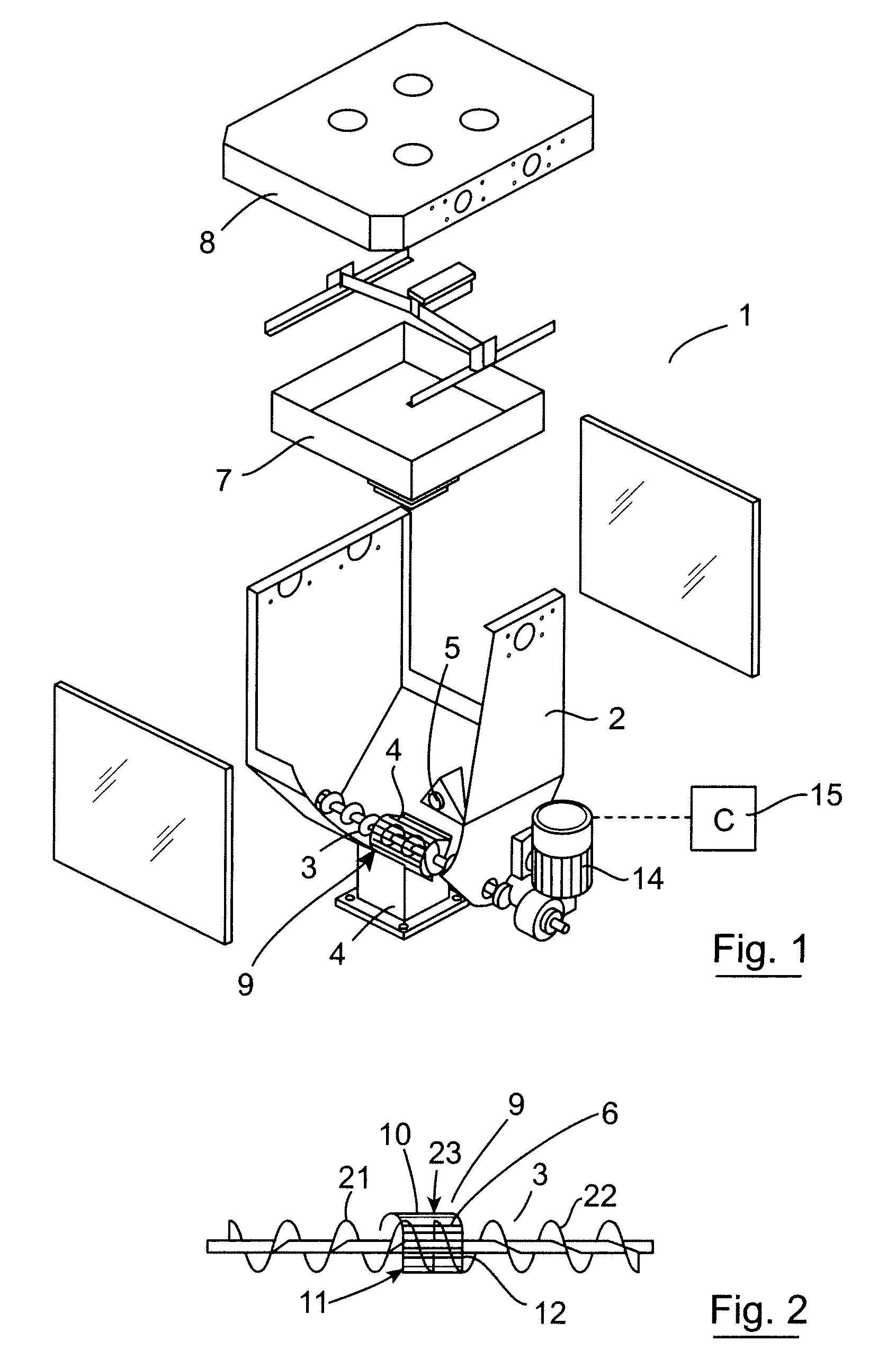

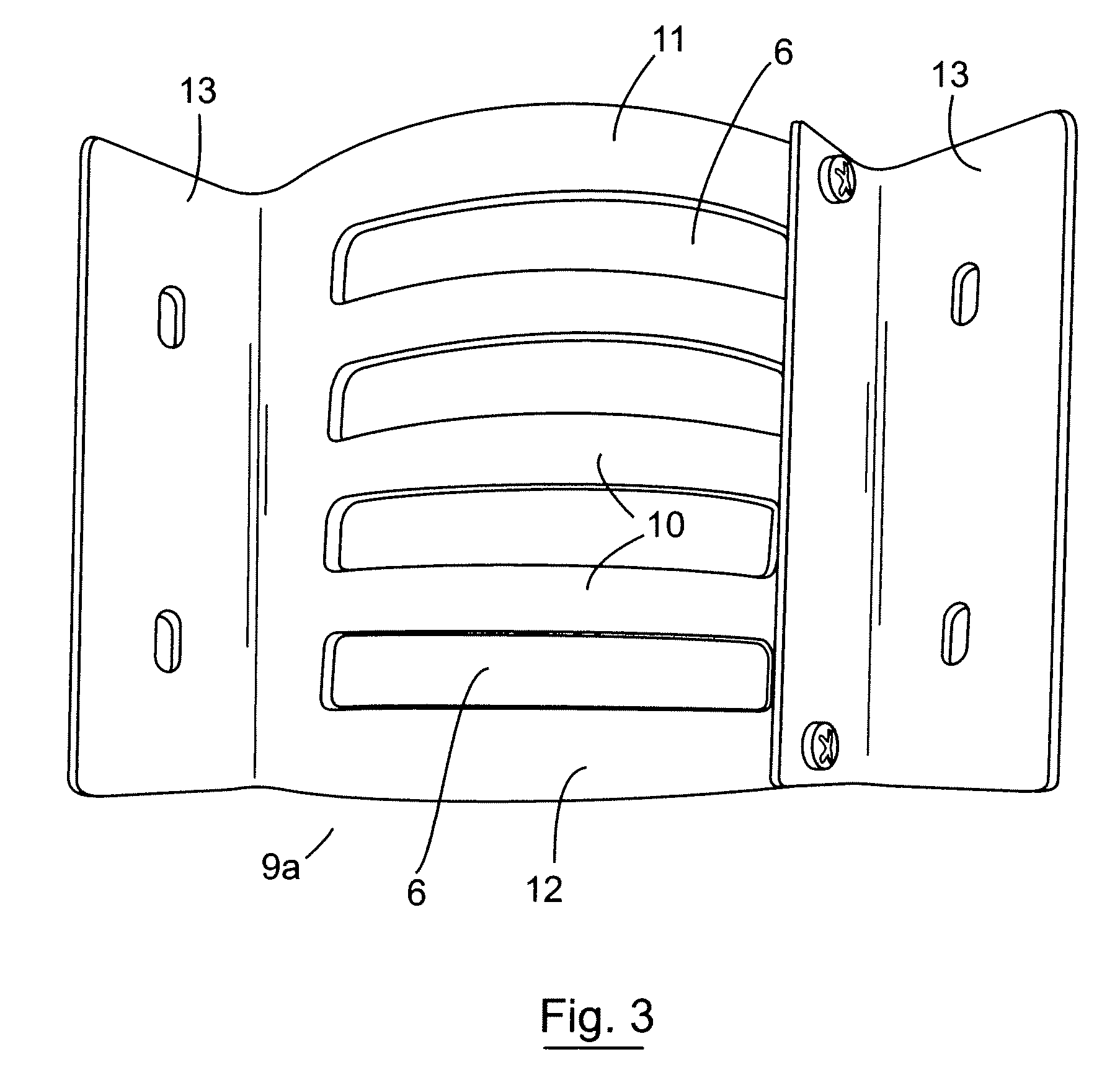

[0062]Referring to the drawings, and initially to FIGS. 1 and 2 thereof, there is illustrated a blender according to the invention indicated generally by the reference numeral 1. The blender 1 is largely similar to our blender described in European Patent Specification No. 0 911 130. The blender 1 has a mixing chamber 2 for reception of materials to be blended. A mixing screw 3 is mounted at a bottom of the mixing chamber 2 adjacent an outlet 4 of the mixing chamber 2 for circulation and mixing of materials within the mixing chamber 2 prior to discharge through the outlet 4. A material level sensor 5 is mounted within the chamber 2 above the screw 3. The level sensor 5 is connected to a controller 15 which is operable to regulate the supply of fresh materials from a weigh hopper 7 to the mixing chamber 2 for mixing. A number of raw material supply bins (not shown) are mounted above a support platform 8 located above the weigh hopper 7 for feeding selected raw material ingredients to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mixture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com