Sawtooth-shaped sand raising plate type sand drying machine

A sawtooth and sand drying machine technology, which is applied in the direction of dryer, drying, sand drying, etc., can solve the problems of poor performance, affecting the stability of production capacity, etc., and achieve the goal of reducing energy loss and increasing the effective heat exchange area Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

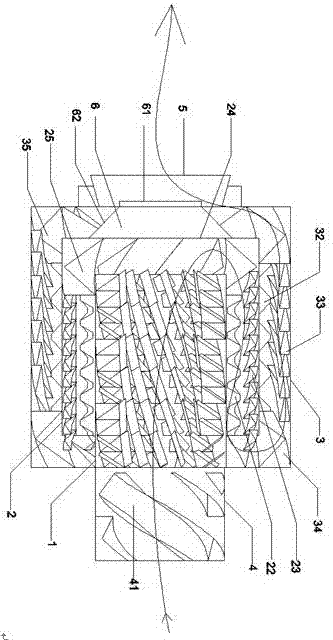

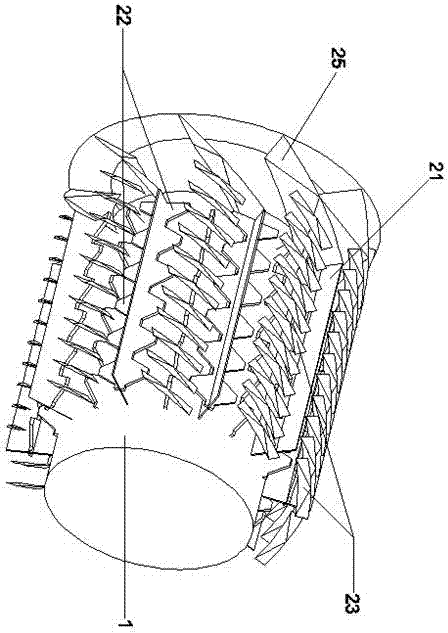

[0025] The present invention will be further described below in conjunction with specific embodiments. In this embodiment, the passage between the inner cylinder 1 and the middle cylinder 2 is called the middle cylinder flow channel; the passage between the middle cylinder 2 and the outer cylinder 3 is called Outer barrel runner.

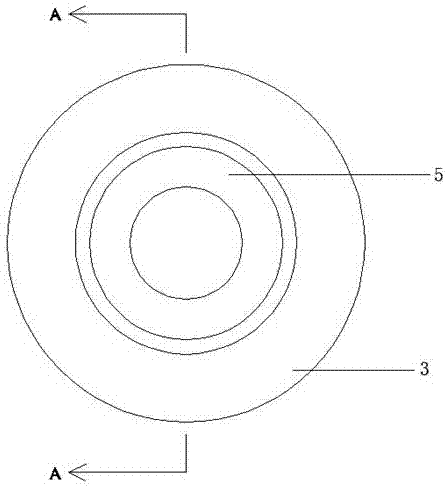

[0026] An embodiment of a sawtooth sand raising plate type sand drying machine provided by the present invention, such as figure 1 , figure 2 and image 3 As shown, the inner cylinder 1 is included, the outer coaxial sleeve of the inner cylinder 1 is provided with the middle cylinder 2, the outer coaxial sleeve of the middle cylinder 2 is provided with the outer cylinder 3, the feeding end of the inner cylinder 1 is provided with the feeding cylinder 4, and the outer cylinder 3 The discharge end is provided with a circumscribed cone 5, which is characterized in that: an inner cylinder sand blowing composite plate is provided on the inner wall of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com