Sintering process air flow online detector and detection method thereof

A technology of air flow and sintering process, applied in the field of sintering, can solve problems such as difficult to reflect the intake air volume, and achieve the effects of easy implementation, uniform air flow velocity distribution, and accurate measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

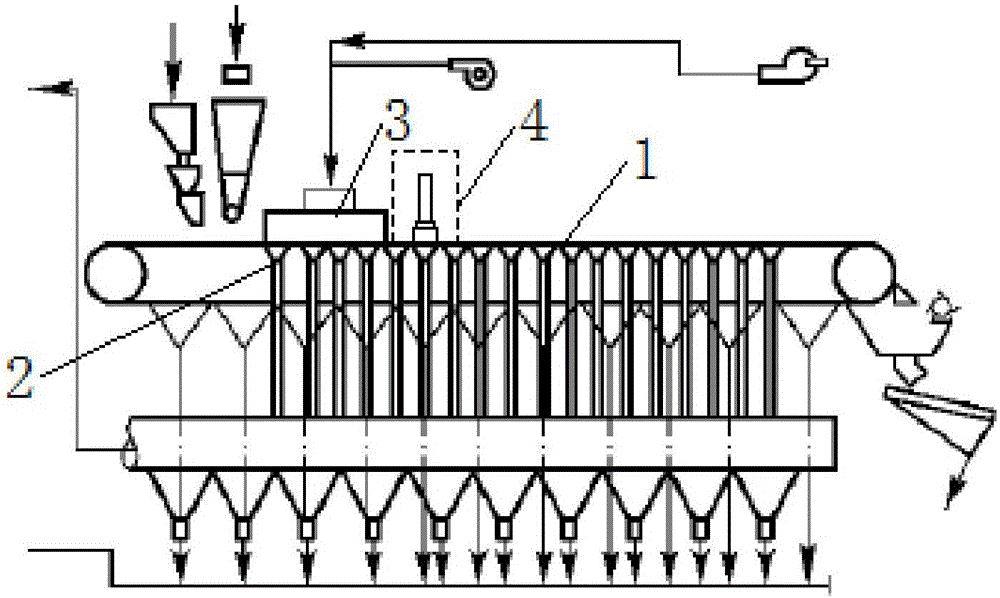

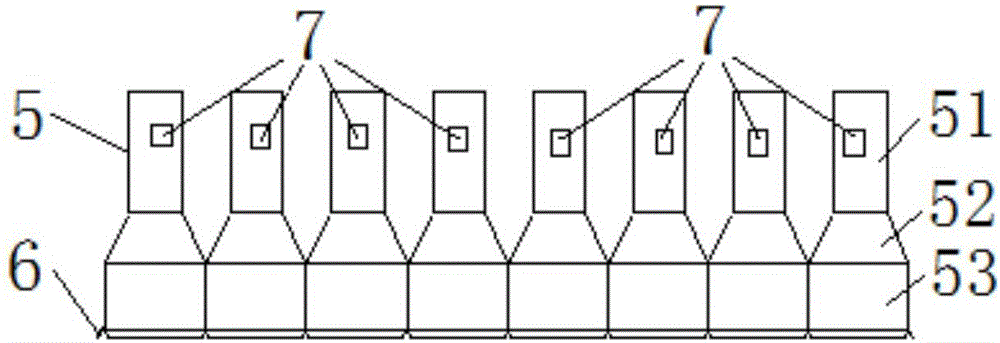

[0054] to combine figure 1 and figure 2 , an on-line detection device for air flow in the sintering process of the present embodiment, mainly composed of a shroud 4 and an air detector 7, etc., when in use, the shroud 4 is placed on the sintering material layer in the middle of the sintering trolley The flow of air flowing through is detected by an air detector 7 . The wind deflector 4 in this embodiment is mainly composed of at least four sub-drain deflectors 5 arranged side by side. The specific number can be selected and designed according to the width of the sintering trolley 1 used. The length of the bottom of the wind deflector 4 is the same as The width of the sintering trolley 1 is matched so that the guide cover 4 covers the sintering material layer in the width direction of the sintering trolley 1 . In this embodiment, four sub-diffusers 5 are provided as an example to illustrate this solution. The four sub-diffusers 5 are arranged side by side along the same stra...

Embodiment 2

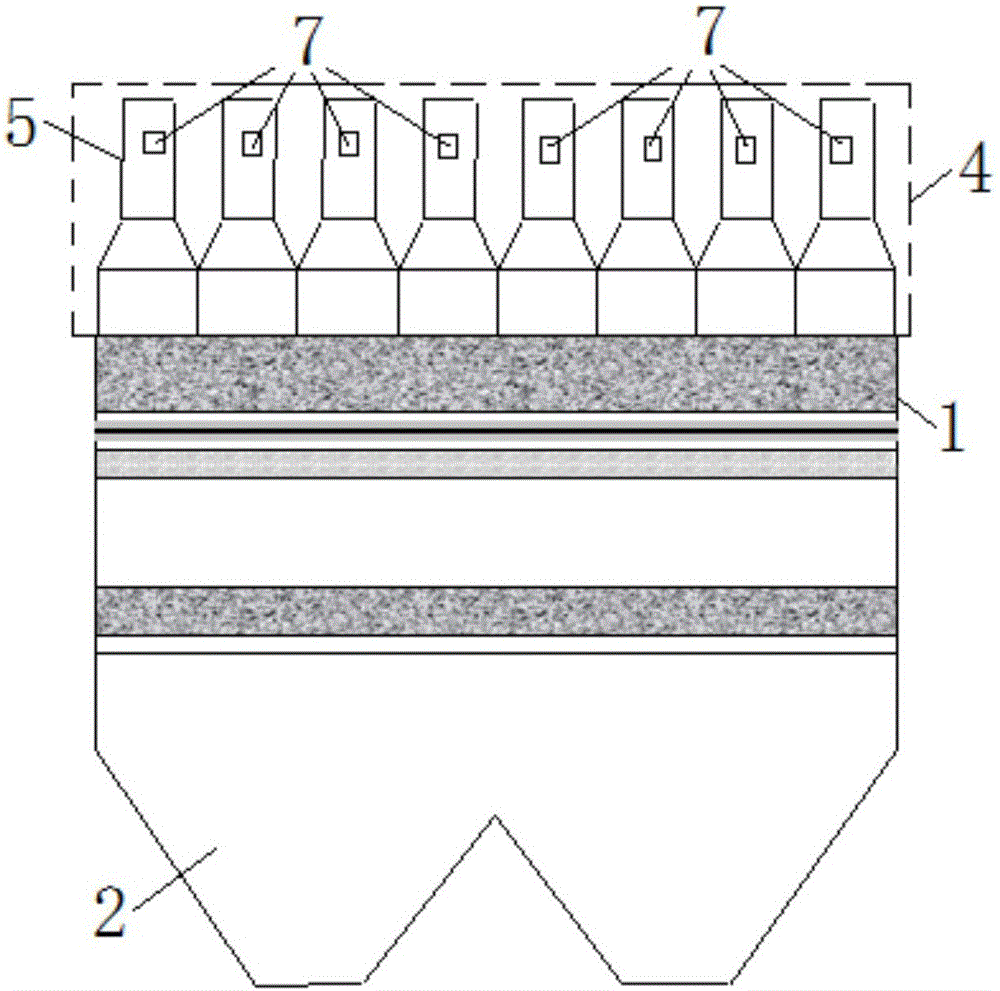

[0058] see figure 1 , figure 2 and image 3 , a kind of on-line detection device of air flow in the sintering process of this embodiment, its basic structure is the same as that of Embodiment 1, and its difference is: in this embodiment, the air guide cover 4 is composed of eight sub-air guide covers 5 arranged side by side along the same direction The inner diameter of the intake pipe 51 is D, the length of the intake pipe 51 is 16D, and the air detector 7 is installed at a position 10D away from the intake pipe 51. After many tests, it is found that the air velocity is more stable in this case, and the measurement The results are also more accurate. In addition, in order to make the air flow rate of the sintered material layer more stable, the exhaust hood provided is a rectangular hood 53 connected to the intake pipe 51 through a transition section 52. The cross section of the rectangular hood 53 is a square. It has less influence on the air velocity and is closer to th...

Embodiment 3

[0061] An online detection device for air flow in the sintering process of this embodiment has the same basic structure as that of Embodiment 2, the difference being that in this embodiment the inner diameter of the air intake pipe 51 is D, the length of the air intake pipe 51 is 18D, and the air The detector 7 is installed at a position 12D away from the intake pipe 51 . The sealing sheet is formed by continuous arrangement of flexible heat-resistant sheets 4 having the same width as the rectangular cover 53 . Due to the uneven surface of the sintered material layer, the use of the segmented sealing sheet structure is better, and the sealing performance of other parts will not be affected by the protrusion of part of the material layer. Because the surface of the sintered material layer is in contact with the air, the temperature is generally within 200°C, and the material of the flexible heat-resistant sheet 4 used is one of Metas needle felt or Flumes needle felt. If the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com