Sand drying device

A drying device, sand technology, applied in the direction of drying gas arrangement, sand drying, drying solid materials, etc., can solve the problems of low drying efficiency, long drying time, poor sand quality, etc., to improve drying efficiency, drying efficiency The effect of improving and increasing the lifespan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

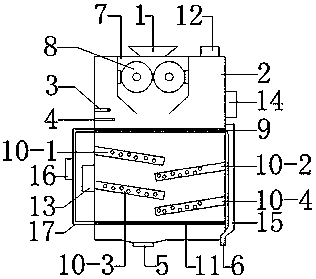

[0020] A sand drying device, mainly comprising: feed inlet 1, drying chamber 2, temperature sensor 3, humidity sensor 4, No. 1 sand outlet 5, No. 2 sand outlet 6 and air outlet 12, wherein the upper end of the device is the inlet Material inlet 1, the air outlet 12 on the right side of the inlet 1, the lower end of the inlet 1 is the drying chamber 2, the upper end of the drying chamber 2 contains a crushing chamber 7, the crushing chamber 7 contains a crushing roller 8, and the lower end of the crushing chamber 7 has a There is a drying pipe 10 at the lower end of No. 1 screen 9 and No. 1 screen 9, and there is a No. 2 screen 11 at the lower end of the drying pipe 10. The left side of the lower end of No. 2 screen 11 is No. 1 sand outlet 5, and the right side is No. 2 sand outlet. Port 6, No. 1 hot air blower 13 on the left side of the drying chamber 2 box, and No. 2 hot air blower 14 on the right side. When using the sand drying device, sand is added to the device from the fe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com