Sleeve type silica sand drying device

A drying device and sleeve-type technology, applied in drying, dryer, sand drying and other directions, can solve the problems of being unsuitable for small-scale industrial use, complicated operation, huge structure, etc., to improve the drying and dust removal effect, and achieve sufficient mixing. , the effect of avoiding air pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

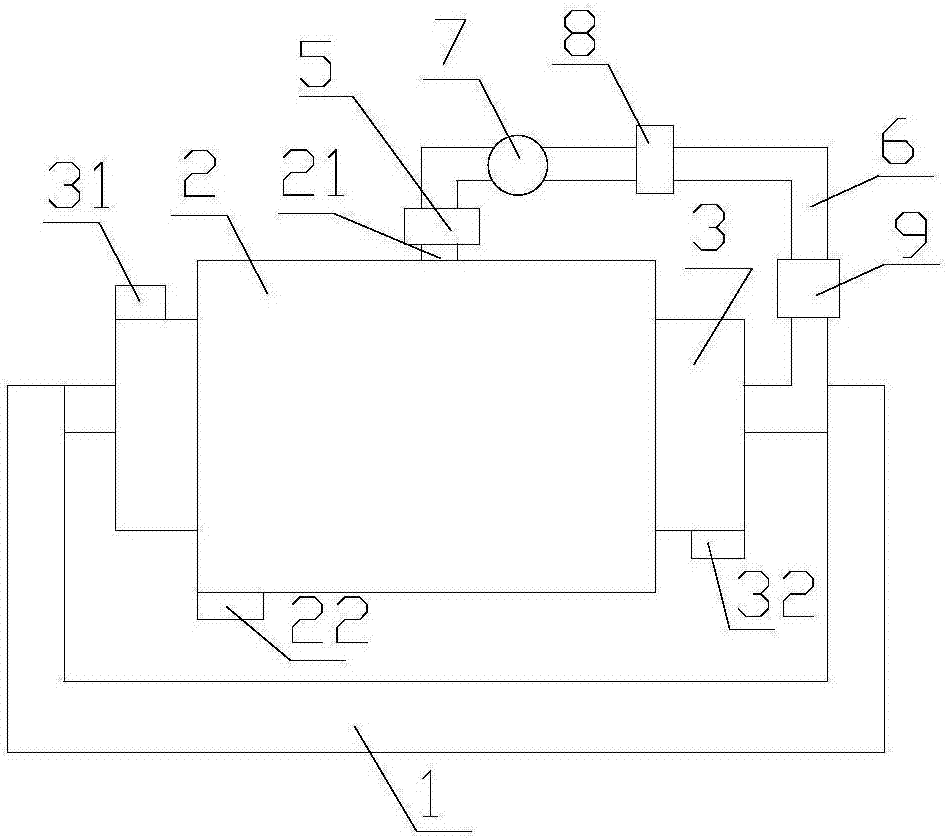

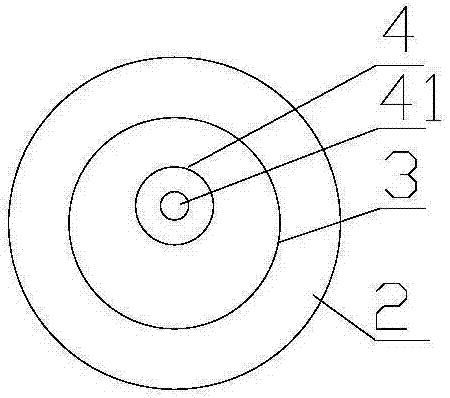

[0016] refer to figure 1 , figure 2 , a sleeve-type silica sand drying device proposed by the present invention includes: a bracket 1, an outer cylinder 2, a rotating cylinder 3 and an inner cylinder 4.

[0017] The rotating cylinder 3 is rotatably installed on the bracket 1 and connected with a driving mechanism. The rotating shaft of the rotating cylinder 3 is parallel to its central axis and arranged eccentrically with the central axis. The outer cylinder 2 is sleeved on the outer circumference of the drum 3 and is sealed with the drum 3. A transition chamber is formed between the outer drum 2 and the drum 3. The drum 3 is provided with a plurality of second tubes connecting the inside of the drum 3 and the transition chamber. Vent. The drum 3 is provided with a feed port 31 and a discharge port 32 which are both located outside the outer cylinder 2, and the feed port 31 and the discharge port 32 are respectively provided with a feed valve and a discharge valve. The out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com