Heat and Water Recovery From Oil Sands Waste Streams

a technology of waste streams and heat and water, which is applied in the direction of drying machines, lighting and heating apparatus, and steam generation using hot heat carriers, etc. it can solve the problems of ineffective tailings storage methods, significant increase in the cost associated with recovering petroleum from bitumen-laden oil sands, and difficulty in separating from extracted sands

Inactive Publication Date: 2011-03-17

EXXONMOBIL UPSTREAM RES CO

View PDF12 Cites 29 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

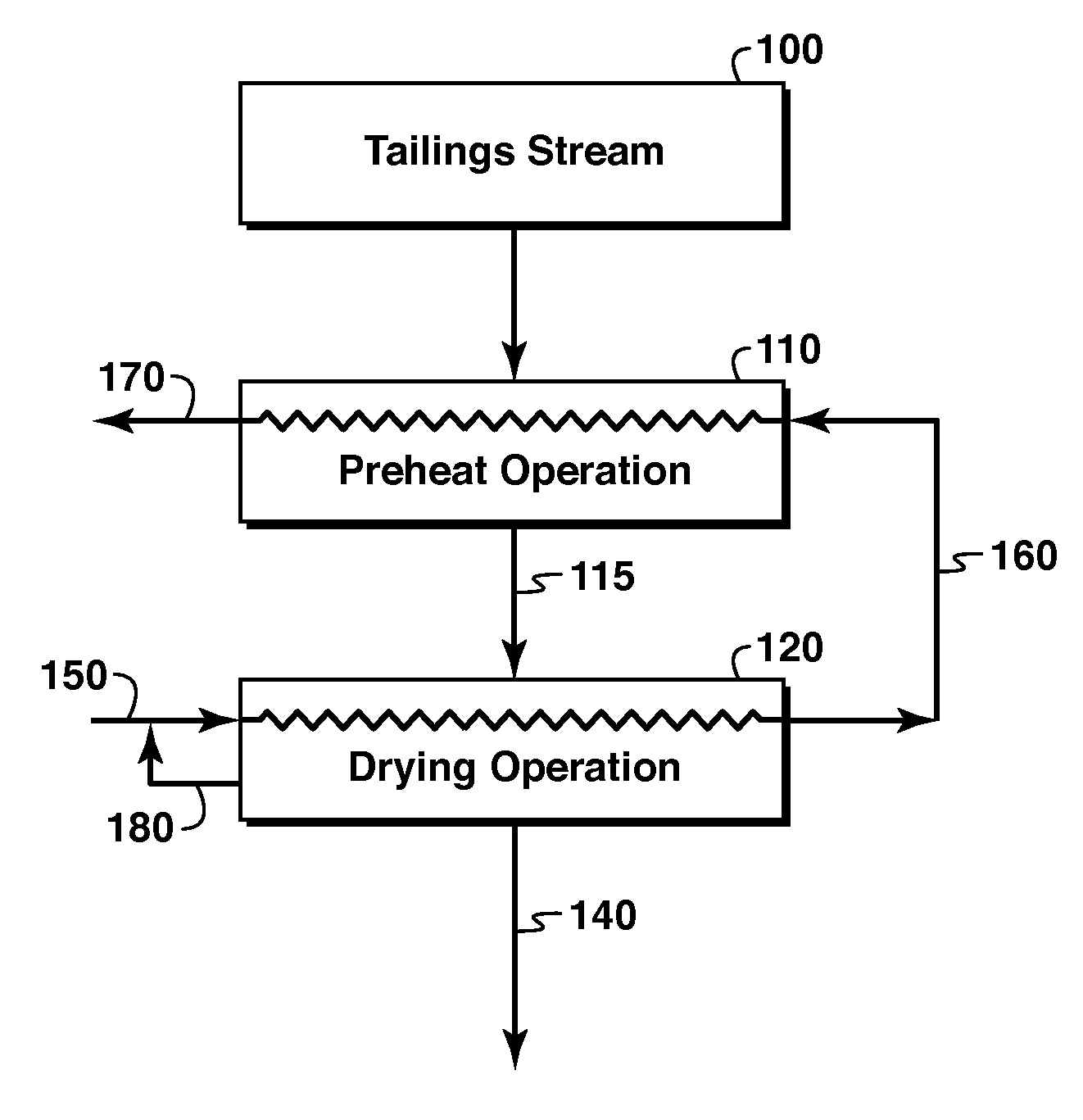

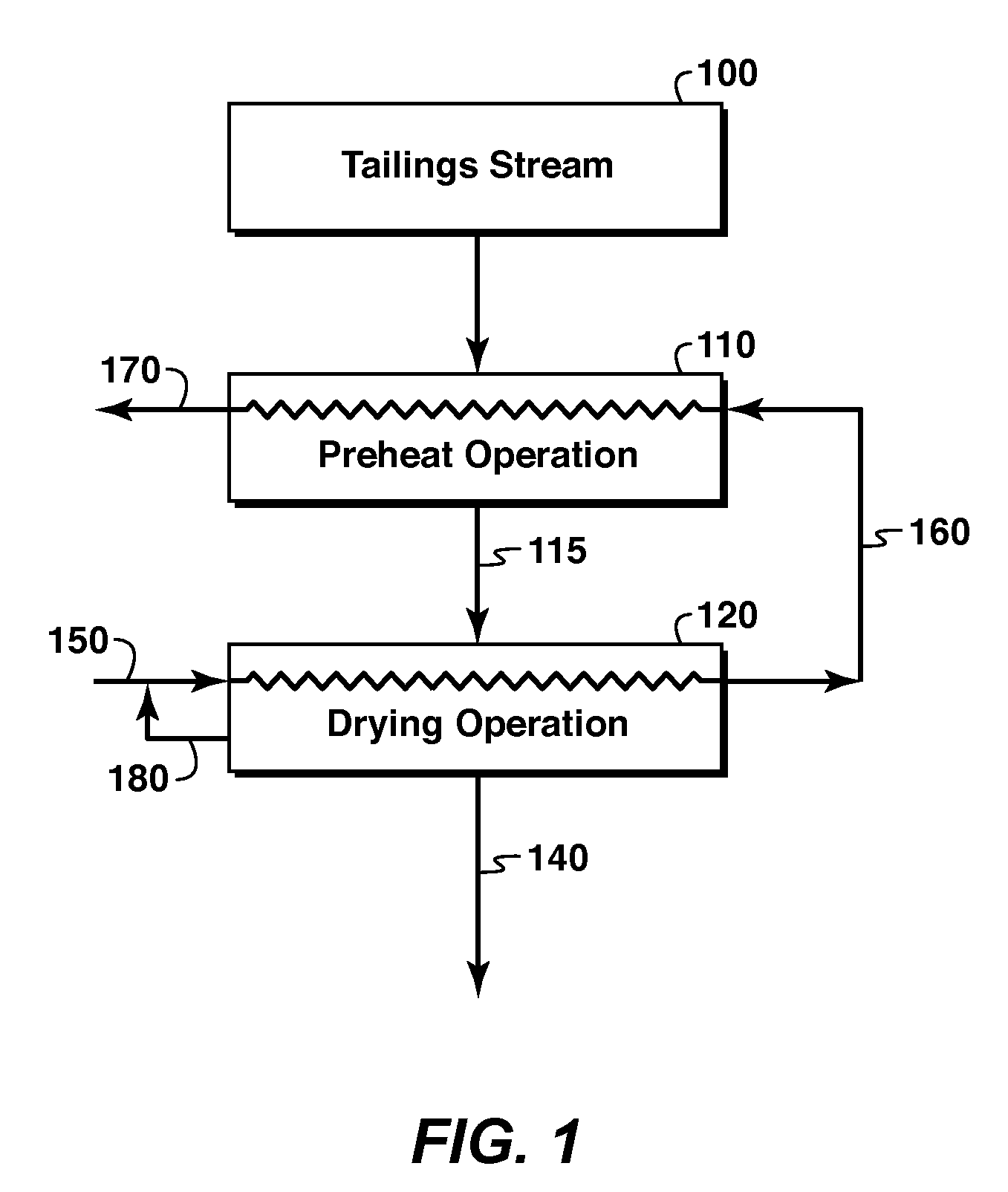

The present invention provides methods and systems for treating tailings produced during oil sands extraction. The invention involves preheating the tailings stream in a heat exchanger using heat from the input steam, and then drying the preheated tailings stream in a dryer using input steam and evaporated water from the preheated tailings. The recovered heat and water are re-used in the preheat operation or the oil sands extraction process, reducing the overall heat and water requirements. The invention also includes a system for recycling steam produced from the dryer back into the dryer. The technical effects of the invention include reducing energy requirements, reducing water requirements, and recycling of resources.

Problems solved by technology

Because the bitumen itself is a highly viscous material, separating it from the extracted sands poses certain practical difficulties.

While effective, the extraction treatment processes require the use of significant quantities of water, and heat to raise the temperature of the water, which significantly increases the cost associated with recovery of petroleum from the bitumen-laden oil sands.

This tailings storage method is ineffective for at least three reasons: firstly, it is not very efficient, as a significant amount of time is required for most of the solid materials to settle out of the tailings by operation of gravity alone; secondly, it does not allow for the recovery of any of the large amount of energy contained within the tailings stream in the form of heat, which is significant, as tailings are initially sent to the ponds for storage at temperatures between 20 and 90° C.; thirdly, the resulting tailings ponds are voluminous, occupying a large footprint of land that cannot be used for any other purposes during the settling process.

There has been, however, a lack of success in effective water and energy recovery.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

example

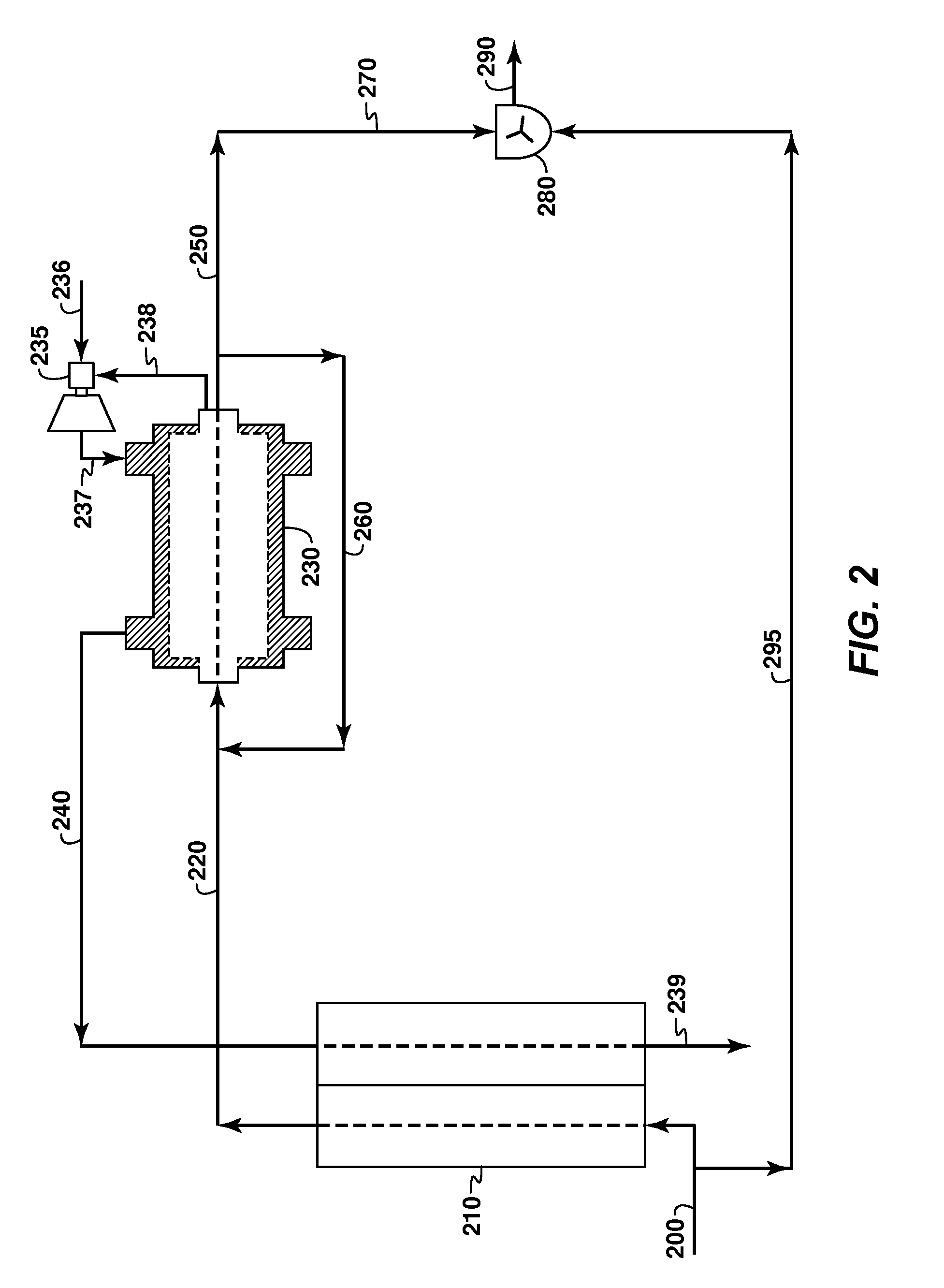

With reference to FIGS. 2 and 3, Table 1 provides flow rates and temperatures, according to one embodiment, for certain streams identified by their reference numbers.

TABLE 1Flow rates and TemperaturesReferenceFlow rateTemperaturenumber (stream)tons per hour(° C.)FIG. 2200282036220254055236100147240205583270580952908657529528036239205560FIG. 322025409023612.51472391950642401950993002820363022540603051100150313103040239 and 312203563together

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

Methods and systems for recovering heat and water from waste streams produced during oil sands extraction to form dry, stackable tailings. A tailings stream is preheated in a heat exchanger, thereby reducing the energy required to dry the tailings. The preheated tailings are then dried, thereby reducing the tailings to dry stackable tailings or thickened tailings suitable for mine backfill. Heat and high-quality water are recovered from the drying operation and re-used in the preheat operation, or in other steps of oil sands extraction or treatment processes, thereby reducing the overall heat and water requirements.

Description

CROSS-REFERENCE TO RELATED APPLICATIONThis application claims priority from Canadian Patent Application 2,677,479 filed 16 Sep. 2009 entitled HEAT AND WATER RECOVERY FROM OIL SANDS WASTE STREAMS, the entirety of which is incorporated by reference herein.FIELD OF THE INVENTIONThe present invention relates generally to recovery of heat and water from waste streams produced during oil sands extraction.BACKGROUND OF THE INVENTIONOil sands are deposits comprised of bitumen, clay, sand, and connate water, and make up a significant portion of North America's naturally-occurring petroleum reserves. To produce a marketable hydrocarbon product from the oil sands, the bitumen must be recovered from the oil sands matrix. Depending on geographic location, bitumen may be recovered by surface mining or in-situ thermal methods, such as steam assisted gravity drainage (SAGD), cyclic steam stimulation (CSS), vapor extraction process (VAPEX), liquid addition to steam for enhancing recovery (LASER) or ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(United States)

IPC IPC(8): F22B1/02

CPCC10G1/045C10G1/047F26B2200/14F26B23/002F26B1/00Y02P70/10

Inventor SPEIRS, BRIAN C.ESMAEILI, PAYMANDUNN, JAMES A.

Owner EXXONMOBIL UPSTREAM RES CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com