Sand screening device for bridge construction

A sand sieve and bridge technology, which is applied in the direction of sieving, solid separation, dry gas arrangement, etc., can solve the problems of sieve hole clogging, insufficient dispersion of sand, and low sieving efficiency, and achieve full sieving , Improve the screening efficiency and promote the volatilization of water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

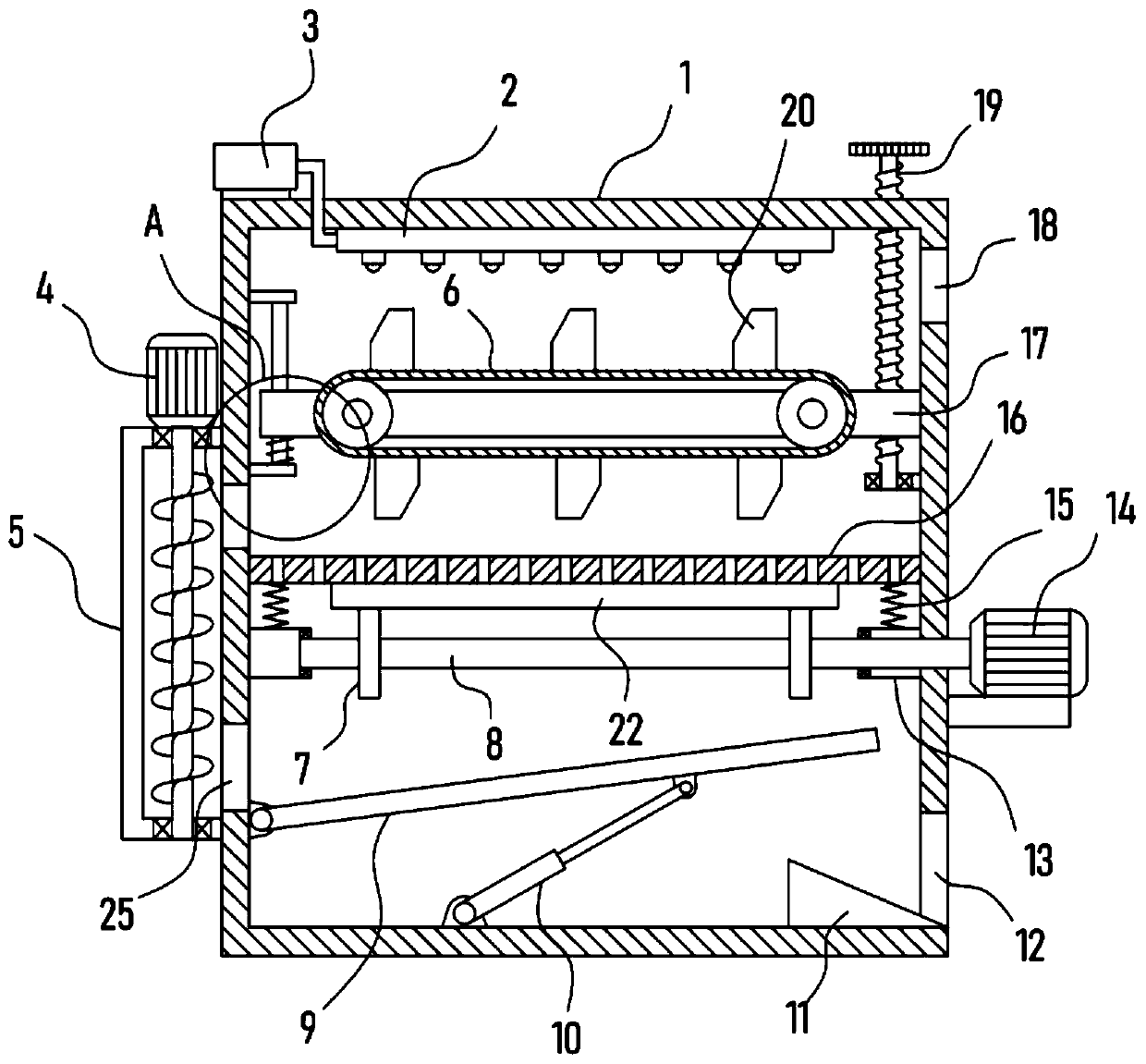

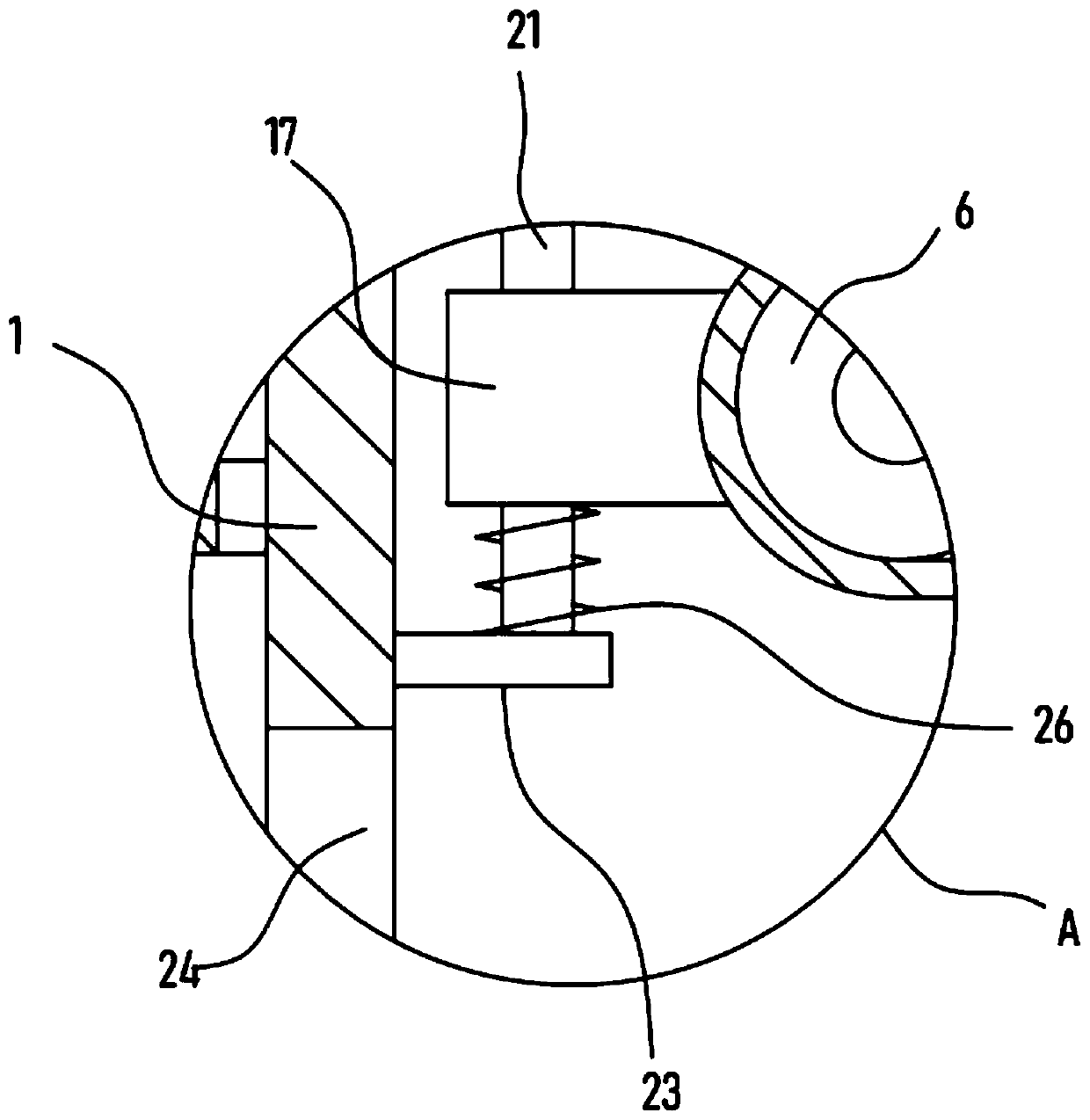

[0021] see Figure 1-3 , a sand screening device for bridge construction, comprising a screening box 1, a horizontally arranged sieve plate 16 is slidably installed in the screening box 1, and it is characterized in that a horizontal frame 17 is provided in the screening box 1, Rotate on the horizontal frame 17 and be provided with conveyor belt 6, the surface of conveyor belt 6 is evenly fixed with several sand taking tanks 20, and the drying mechanism vertically corresponding to conveyor belt 6 is fixed on the top of described screening box 1, and described sieve A servo motor II14 is fixed outside the sub-box 1, and the servo motor II14 is driven and connected with an exciting mechanism connected with the sieve plate 16 in transmission.

[0022] When screening the sand, the sand is placed on the sieve plate 16 in the screening box 1, and the relatively fine sand passes through the sieve holes to realize the screening and separation of the sand, and the rotation of the conve...

Embodiment 2

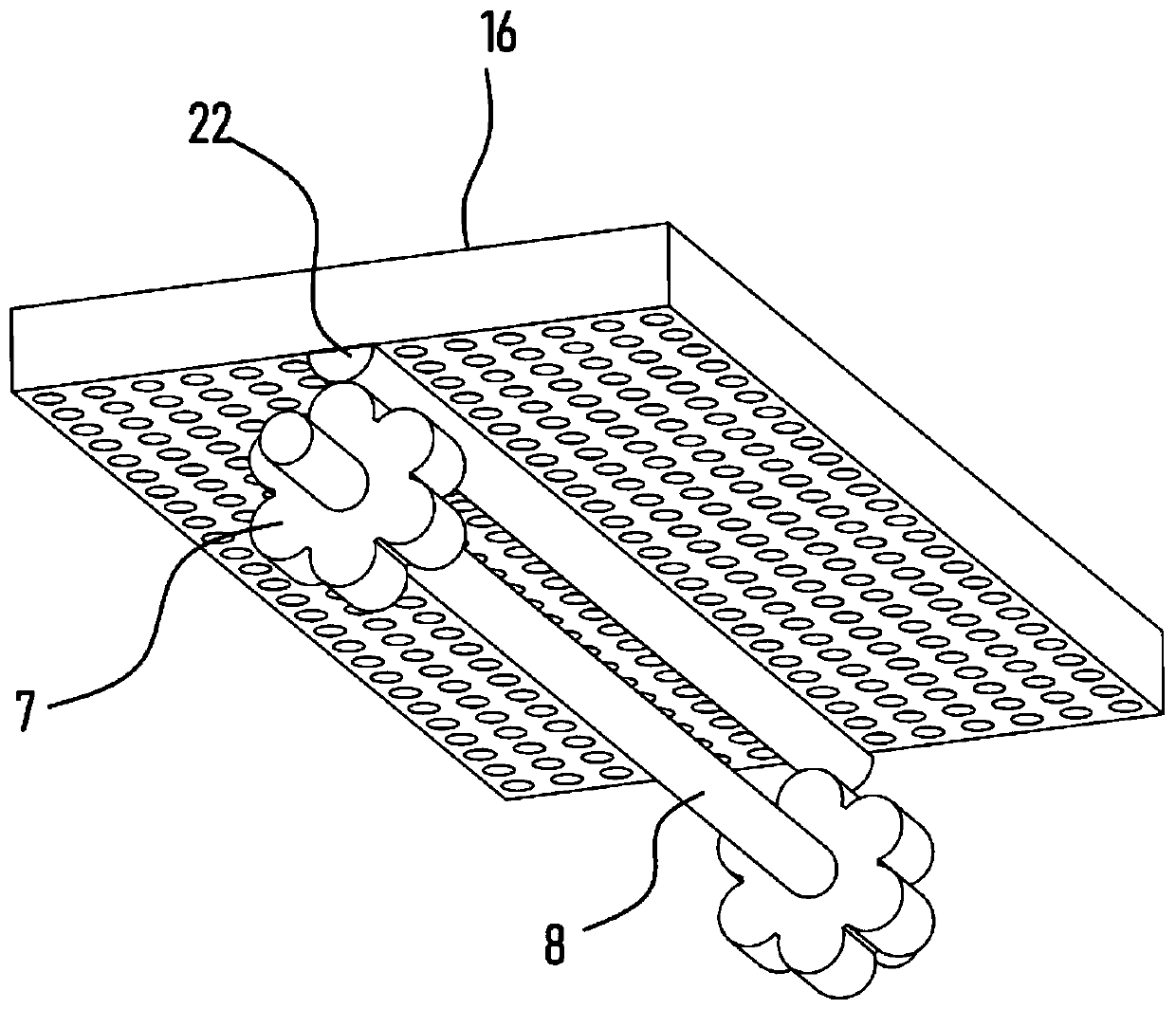

[0029] In order to further accelerate the sand screening efficiency of the screening box 1, on the basis of Embodiment 1, the vibration excitation mechanism includes a rotating shaft 8 coaxially fixed with the output shaft of the servo motor II14, and the surface of the rotating shaft 8 is evenly distributed in the circumferential direction. Several transmission blocks 7 are fixed, and the bottom of the sieve plate 16 is fixed with a convex line 22 abutting against the transmission blocks 7, and the sieve plate 16 is vertically slidingly connected with the screening box 1 through an elastic connection assembly.

[0030] The servo motor II14 is used to drive the rotating shaft 8 to realize its rotation, and the rotating shaft 8 drives the transmission block 7 on it to rotate, and the transmission block 7 and the convex strip 22 contact and drive to realize the sieve plate 16 under the elastic action of the elastic connection assembly. Vibrating up and down accelerates the vibrat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com