Latent polythiol curing agent, and synthetic method and application of latent polythiol curing agent

A synthetic method, polythiol technology, applied in the direction of organic chemistry, can solve the problems of complex process, discomfort, low olfactory threshold, etc., and achieve the effect of simple synthesis process, wide application prospect and wide source

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

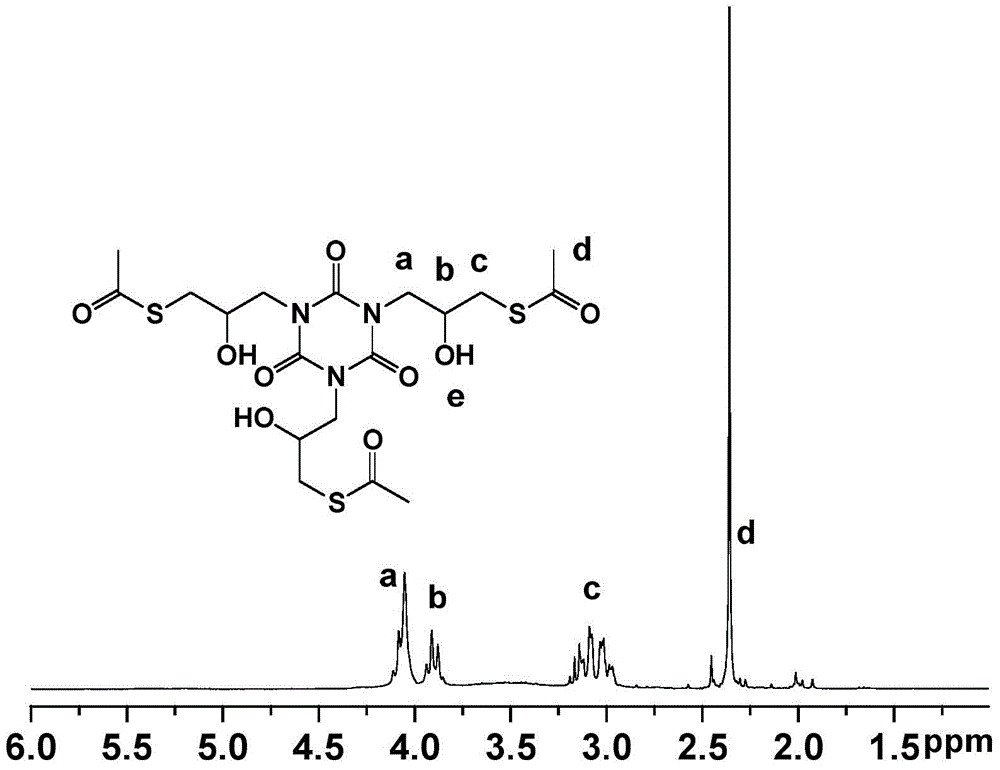

[0031] Into the reactor, successively add triglycidyl isocyanurate containing 1 mole part of epoxy group and 1.01 mole part of thioacetic acid, react at -10°C for 24 hours, and remove excess sulfur by evaporation under reduced pressure Substitute acetic acid, obtain latent polythiol curing agent, its 1 H NMR spectrum see figure 1 , the latent polythiol curing agent can be stored stably, is not easy to deteriorate, and has no sulfur odor.

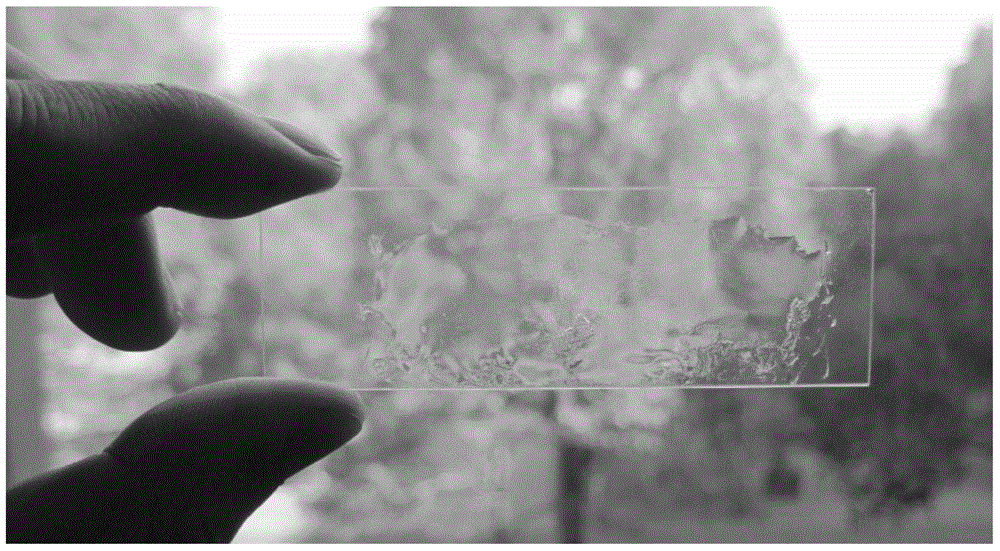

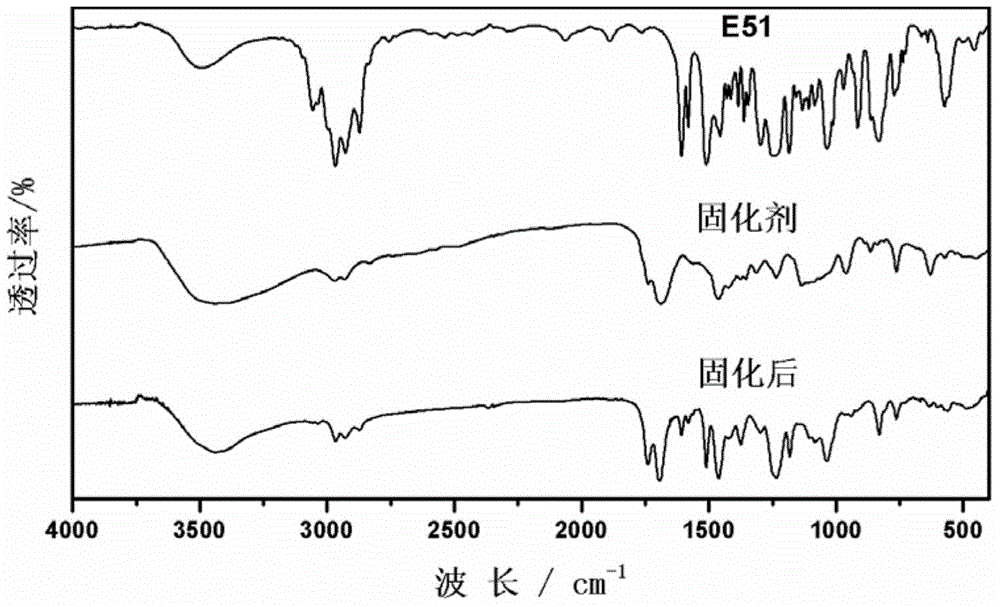

[0032] Mix the obtained latent polythiol curing agent containing 1 mole of β-hydroxy thiocarboxylate and bisphenol A epoxy resin (E51) containing 0.6 mole of epoxy group evenly, and react at 100°C for 10 minutes to obtain Polymer, the transparent coating formed on transparent glass by this polymer can refer to figure 2 , and its infrared spectrum can be found in image 3 .

Embodiment 2

[0034] Into the reactor, successively add triglycidyl isocyanurate containing 1 mole part of epoxy group and 1.5 mole parts of thiobenzoic acid, react at 30 ° C for 1 hour, and remove excess sulfur by column chromatography Substitute benzoic acid to obtain latent polythiol curing agent.

[0035] The resulting latent polythiol curing agent containing 1 mole of β-hydroxythiocarboxylate, bisphenol A epoxy resin containing 1.2 moles of epoxy groups and 0.05 moles of N,N-dimethylaminopyridine were mixed Uniform, reacted at 0°C for 48 hours to obtain a polymer.

Embodiment 3

[0037] Add bisphenol A type epoxy resin containing 1 mole of epoxy group and 1.1 mole of monothiobenzoic acid to the reactor successively, react at -5°C for 22 hours, and remove excess monothiobenzoic acid by column chromatography. Benzoic acid, latent polythiol curing agent.

[0038] Mix the obtained latent polythiol curing agent containing 1 mole of β-hydroxy thiocarboxylate, bisphenol F type epoxy resin containing 0.7 mole of epoxy group and 0.005 mole of triethylamine, and mix them uniformly at 10°C The reaction was carried out for 10 hours to obtain a polymer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com