Filling paint transportation device

A transportation device and paint technology, applied in the direction of transportation and packaging, packaging, packaging items, etc., can solve the problems of paint leakage, paint bucket crushing, affecting the later use of paint, etc., to prevent deformation and damage, easy installation and disassembly, reduce The effect of heat transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

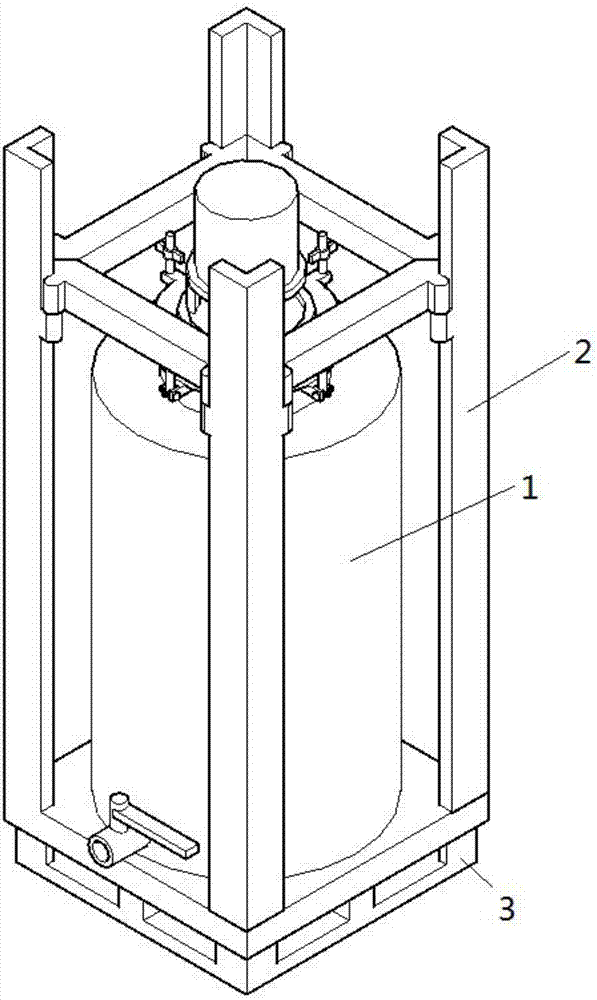

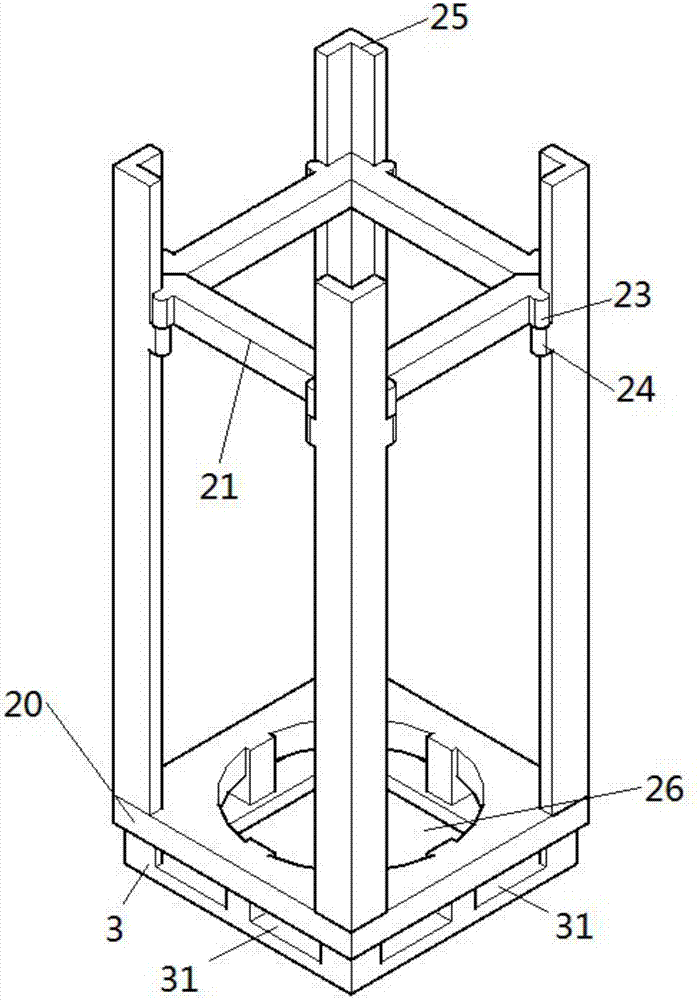

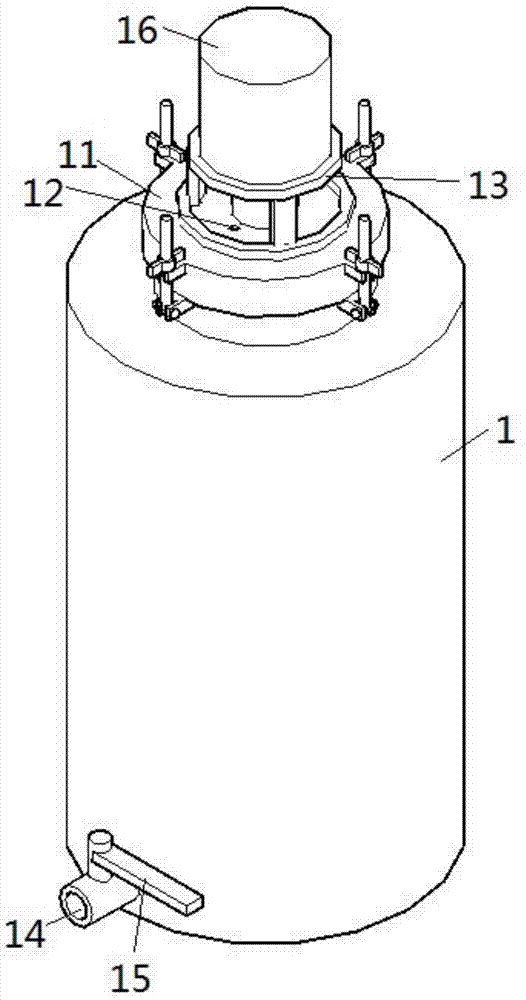

[0027] Figure 1 to Figure 6 As shown, it relates to a filling paint transportation device, including a loading and unloading rack, and a paint bucket arranged in the loading and unloading rack; wherein, the loading and unloading rack includes a base 20 arranged in a square shape, and is arranged on the base 20 The barrel guard 2; wherein the bottom of the base 20 is provided with a forklift fixed seat 3, the interior of the forklift fixed seat 3 is in a hollow state, and its surroundings are respectively provided with sockets 31 matching the forks of the forklift; Wherein, the barrel protection frame 2 includes a right-angle pillar 25 that is perpendicular to the base 20 and extends upwardly installed at the four corners of the base 20; the bottom of each right-angle pillar 25 passes through a screw structure ( Not shown) is screwed to the base 20; between the right-angle pillars 25, located on the upper part of the paint bucket 1 is provided with a support for limiting the ne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com