Environment-friendly transfer printing ink and preparing method and application thereof

An ink and environmental protection technology, applied in the direction of ink, application, printing, etc., can solve the problems of weak adhesion, etc., and achieve the effect of easy operation, low production cost and stable colloidal properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

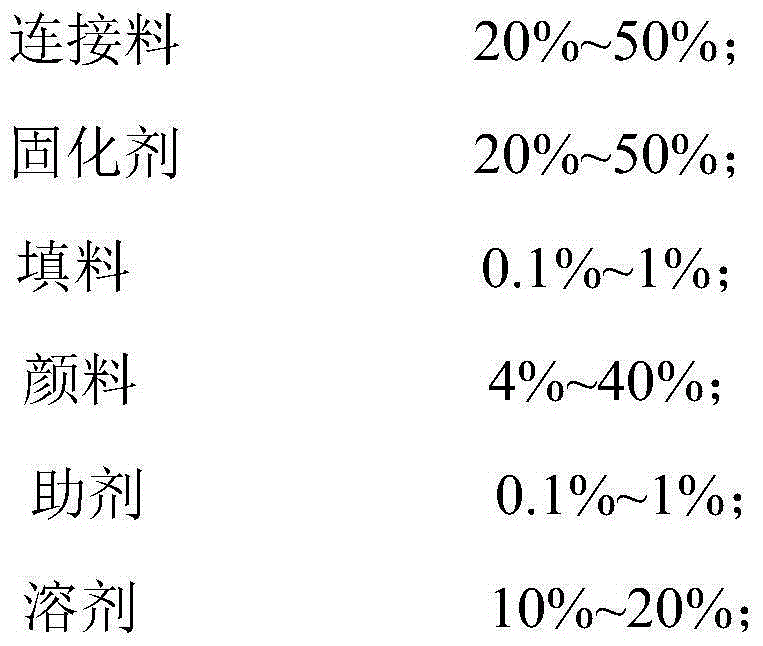

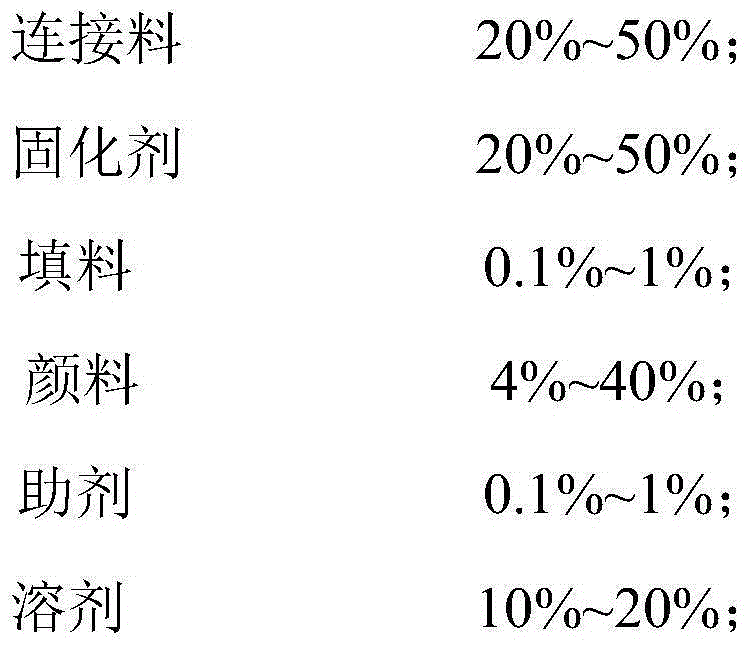

preparation example Construction

[0027] Correspondingly, on the basis of the formulation of the environmentally friendly pad printing ink in the above embodiment of the present invention, the embodiment of the present invention also provides a preparation method of the environmentally friendly pad printing ink. In one embodiment, the preparation method of the environmentally friendly pad printing ink specifically includes the following steps:

[0028] Step S01: weighing each component according to the above ink formula;

[0029] Step S02: Mix and fully wet the weighed components, and then grind to prepare the environmentally friendly pad printing ink of the embodiment of the present invention.

[0030] Specifically, in the above step S02, in order to make the components of the environmentally friendly pad printing ink uniform and the system stable, it should be fully stirred to make the mixture uniform, and then fully wetted.

[0031] In a specific embodiment, a three-roll machine may be used for grinding in...

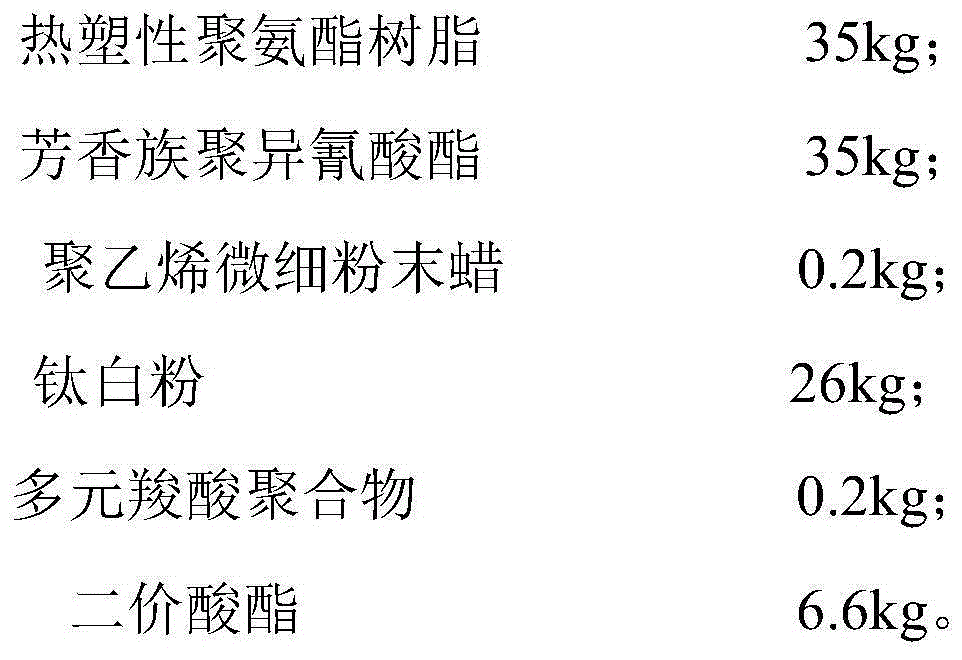

Embodiment 1

[0037] An environmentally friendly pad printing ink and a preparation method thereof. Among them, the environmentally friendly pad printing ink is composed of the following components by weight:

[0038]

[0039] The preparation method of this environment-friendly pad printing ink comprises the steps:

[0040] First, according to the weight of each component provided in Example 1, weigh thermoplastic polyurethane resin, aromatic polyisocyanate, polyethylene fine powder wax, titanium dioxide, polycarboxylic acid polymer and dibasic acid ester; secondly, weigh The components are fully stirred until they are evenly mixed and fully wetted; finally, they are ground with a three-roller machine to a fineness of 5um or less, and then white environmentally friendly pad printing ink can be made.

Embodiment 2

[0042] An environmentally friendly pad printing ink and a preparation method thereof. Among them, the environmentally friendly pad printing ink is composed of the following components by weight:

[0043]

[0044] The preparation method of this environment-friendly pad printing ink comprises the steps:

[0045] First, according to the weight of each component provided in Example 2, take thermoplastic polyurethane resin, aromatic polyisocyanate, polytetrafluoroethylene copolymer fine powder wax, carbon black, polysiloxane interpolymer and dibasic acid ester; Secondly, fully stir the weighed components until they are evenly mixed and fully wetted; finally, use a three-roll machine to grind to a fineness of 5um or below, and then the black environmentally friendly pad printing ink can be made.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com