Water-proof self-luminous printing film

A self-illuminating and waterproof technology, applied in the chemical industry, can solve the problems of impossibility of waterproofing, large absorption capacity, long drying time, etc., and achieve good color reproduction effect, true image color and fast drying speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

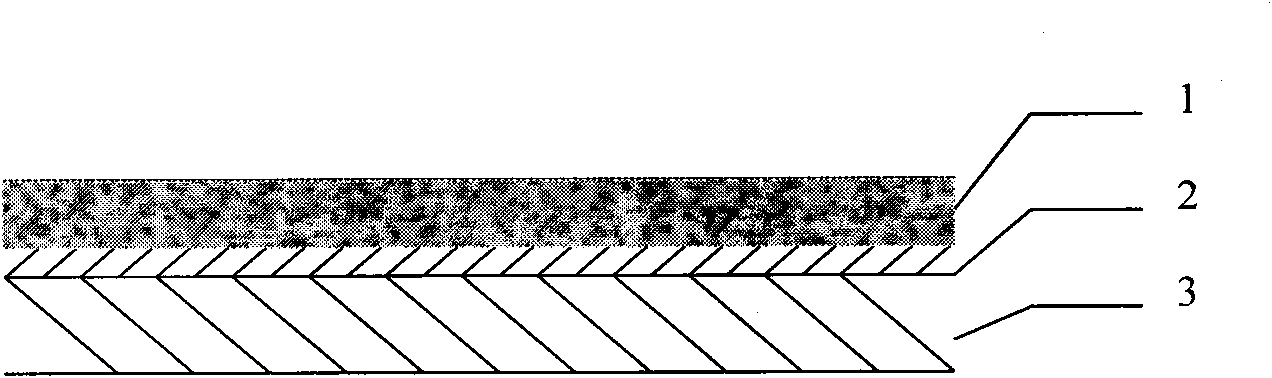

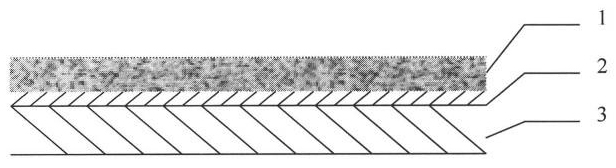

Image

Examples

Embodiment 1

[0037] Light-storing photoluminescent film:

[0038] Plastic film containing aluminate-type light-storing luminescent material emitting yellow-green light

[0039] Ink Receiving Layer Formulation:

[0040] Inorganic filler Aluminum hydroxide 27.4%

[0041] Binder Polyvinyl Alcohol 2.7%

[0042] Fixing agent Dimethyl diallyl ammonium chloride 11.7%

[0043] Coupling agent 3-aminopropyltriethoxysilane 1.5%

[0044] Surfactant Nonylphenol ethoxylate 0.9%

[0045] Cross-linking agent boric acid 0.9%

[0046] Fluorescent whitening agent TA (stilbene type) 0.1%

[0047] Water 54.8%

[0048] operate:

[0049] 1) Stir the adhesive with water until it is uniformly dissolved, and prepare an aqueous adhesive solution with a mass concentration of 10%;

[0050] 2) Add inorganic fillers, color fixing agents, coupling agents, surfactants, crosslinking agents, and fluorescent whitening agents into water and mix evenly, and disperse at a speed of 2000r / min for 4 hours;

[0051] 3) Sl...

Embodiment 2

[0055] Light-storing photoluminescent film:

[0056] Plastic film containing aluminate-type light-storing luminescent material emitting yellow-green light

[0057] Ink Receiving Layer Formulation:

[0058] Inorganic filler Aluminum hydroxide 13.7%

[0059] Silica 13.7%

[0060] Binder Polyvinyl Alcohol 2.75%

[0061] Fixing agent Dimethyl diallyl ammonium chloride 11.65%

[0062] Coupling agent 3-glycidyl etheroxypropylmethyldiethoxysilane 1.46%

[0063] Cationic surfactant dosage: benzalkonium chloride (geeramine) 0.95%

[0064] Cross-linking agent boric acid 0.9%

[0065] Fluorescent whitening agent TA (stilbene type) 0.09%

[0066] Water 54.8%

[0067] operate:

[0068] 1) Stir the adhesive with water until it is uniformly dissolved, and prepare an aqueous adhesive solution with a mass concentration of 10%;

[0069] 2) Add inorganic fillers, color fixing agents, coupling agents, surfactants, crosslinking agents, and fluorescent whitening agents int...

Embodiment 3

[0074] Light-storing photoluminescent film:

[0075] Plastic film containing aluminate-type light-storage-type luminescent material emitting blue-green light

[0076] Ink Receiving Layer Formulation:

[0077] Inorganic filler Silica 27.7%

[0078] Binder Polyvinyl Alcohol 2.75%

[0079] Fixing agent Dimethyl diallyl ammonium chloride 11.9%

[0080] Coupling agent 3-glycidyloxypropylmethyldiethoxysilane 1.5%

[0081] Cross-linking agent Glutaraldehyde 0.9%

[0082] Water 55.25%

[0083] operate:

[0084] 1) Stir the adhesive with water until it is uniformly dissolved, and prepare an aqueous adhesive solution with a mass concentration of 10%;

[0085] 2) Add inorganic fillers, color fixing agents, coupling agents, surfactants, crosslinking agents, and fluorescent whitening agents into water and mix evenly, and disperse at a speed of 3000r / min for 4 hours;

[0086] 3) Slowly add the aqueous binder solution, continue to stir at a speed of 3000r / min for 1 hour, and let it s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com