Full-automatic glue brushing line for shoemaking

A fully automatic, glue brushing technology, applied in the direction of pretreatment surface, coating, surface coating liquid device, etc., can solve the problems of easy glue blocking, insufficient glue adhesion, uneven glue quantity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

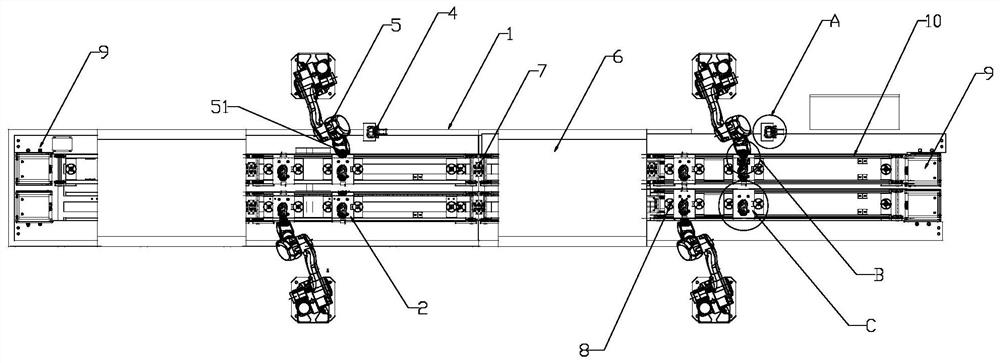

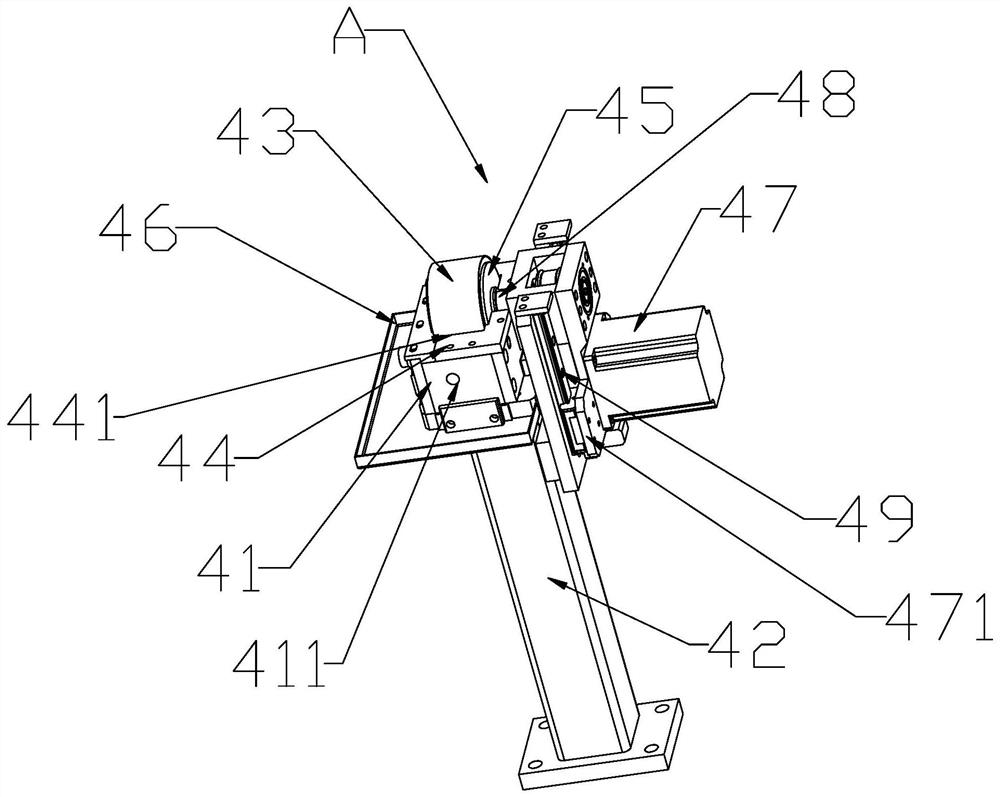

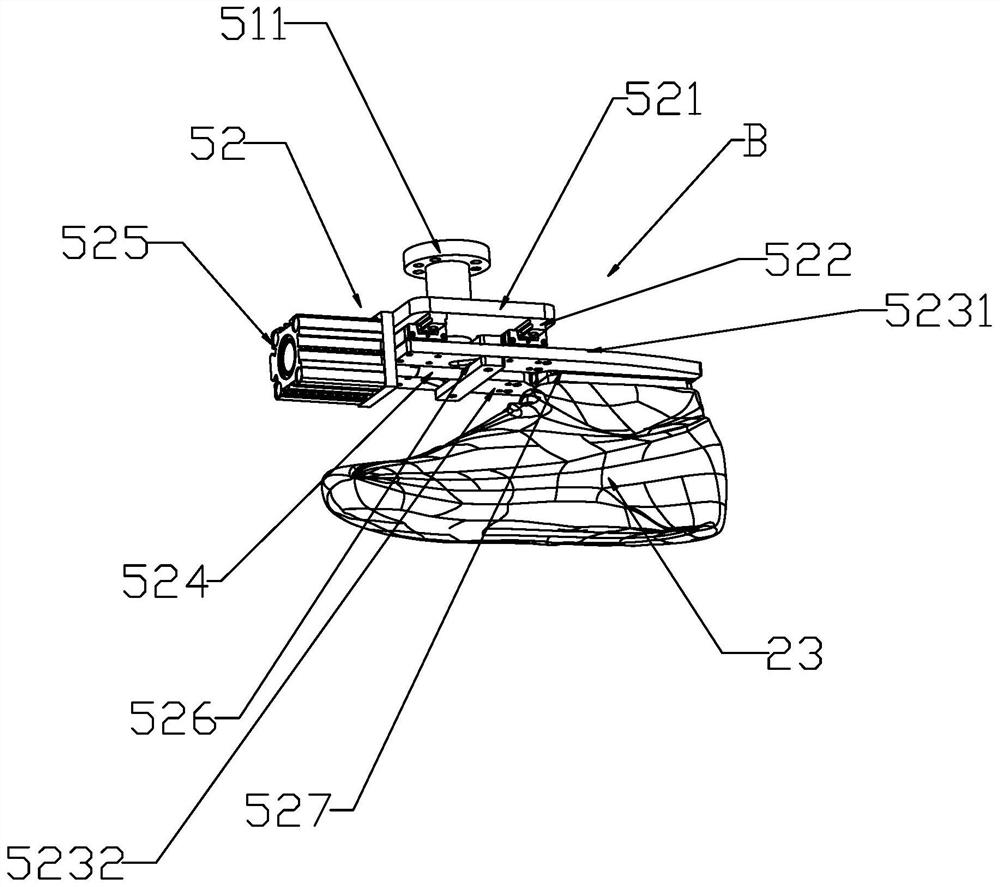

[0089] A fully automatic glue brushing line for shoemaking, such as Figure 1-5 As shown, it includes: a frame 1, a shoe last positioning plate 2, a positioning mechanism 3, a robot assembly 5, a glue brushing system 4, and a control system; the control system is used to control the transmission device 10, the positioning mechanism 3, and the robot Component 5 and gluing system 4. The frame 1 is provided with a conveying device 10 for conveying the shoe last positioning board 2. The conveying device 10 includes transmission chains or belts respectively arranged on both sides of the machine tool. The length direction of the shoe last positioning plate 2 is set across the transmission chains or belts on both sides for transmission. The shoe last positioning plate 2 is used for positioning the shoe last 23; the positioning mechanism 3 is arranged on the frame 1, the positioning mechanism 3 is used for positioning the shoe last positioning plate 2, and the conveying device 10 wil...

Embodiment 2

[0120] This embodiment only describes the differences from the above-mentioned embodiments, and the similarities between this embodiment and the above-mentioned embodiments will not be repeated. In this embodiment, the limiting plate 24 is a straight plate, and one end of the straight plate extends upwards. out of the upper surface of the shoe last positioning plate 2, the other end of the straight plate extends downward and is placed outside the transmission chain or belt in the conveying device 10, and the limiting plate 24 is positioned with the shoe last The connection position of the plate 2 is close to the upper end of the limiting plate 24, the positioning sensor 22 is arranged on the upper end of the limiting plate 24, or the positioning sensor 22 is arranged on the upper end of the limiting plate 24 and Between the joint of the limiting plate 24 and the shoe last positioning plate 2 .

Embodiment 3

[0122] This embodiment only describes the differences from the above-mentioned embodiments, and the similarities between this embodiment and the above-mentioned embodiments will not be repeated. In this embodiment, the bottom of the stop roller 8 is connected to a cylinder device. When the shoe last positioning plate 2 After completely passing the stop roller 8 on one side of the positioning mechanism 3, that is, after detecting that both sides of the shoe last positioning plate 2 have passed the stop roller 8, the stop roller 8 rises, thereby limiting the subsequent shoe last positioning plate 2 to continue to Front conveying ensures that there is only one shoe last positioning plate 2 above each positioning mechanism 3. When the shoe last positioning plate 2 leaves the positioning mechanism 3, the stop roller 8 descends, and the shoe last positioning plate 2 passes through the stop on the other side of the positioning structure. The rollers 8 continue to be transported forwar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com