Intravenous medicine carrier material and its prepn process

A carrier material, intravenous drug technology, applied in the direction of non-active components of polymer compounds, etc., can solve problems such as limited application scope, and achieve the effects of easy to master, standardized equipment, and widely available sources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] The intravenous drug carrier material of this embodiment is made of commercially available gelatin (Wenzhou Huabao Gelatin Co., Ltd.) as the base material.

[0056] Its preparation method is:

[0057] 1) gelatin is formulated into an aqueous solution according to 3% by weight;

[0058] 2) According to the weight ratio of gelatin and proteolytic enzyme is 100:1, add neutral protease into gelatin solution, and degrade at 50° C. for 60 min;

[0059] 3) According to the weight ratio of gelatin and cross-linking agent of 100:2, the glutaraldehyde aqueous solution was added to the gelatin degradation solution, and the cross-linking reaction was carried out at 25° C. for 20 h;

[0060] 4) The cross-linking reaction product is filtered and dried at 45°C for 20 hours to form a material.

[0061] The material prepared by the above method was mixed with urokinase to prepare a solution as the injection of the test group, and the solution prepared with simple urokinase was used as...

Embodiment 2

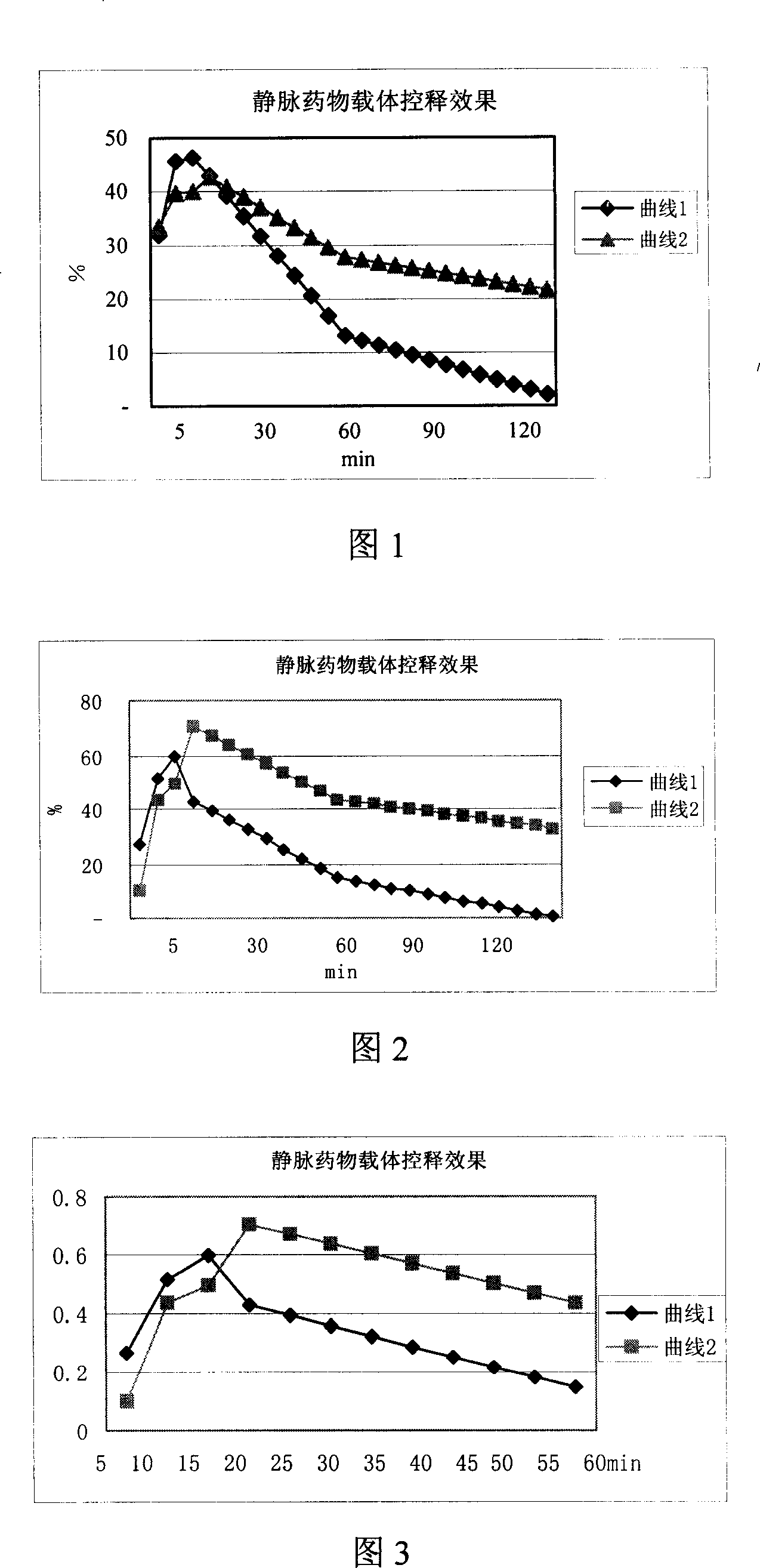

[0064] The method and equipment are basically the same as in Example 1, except that the gelatin in this example is formulated into an aqueous solution at 5% by weight; the crosslinking agent is a carbodiimide solution, and the crosslinking reaction is carried out at 5° C. for 12 hours. The measurement results of dynamic fibrinolysis rate are shown in curve 1 and curve 2 of Fig. 2 .

[0065] Figure 2 dynamic fibrinolysis rate

[0066] Curve 1 is the dynamic fibrinolysis rate of simple urokinase.

[0067] Curve 2 is the dynamic fibrinolysis rate of carrier-urokinase complex.

[0068] It can be seen from the figure that the intravenous drug carrier material of this embodiment has a good controlled release effect.

Embodiment 3

[0070] The method and equipment are basically the same as in Example 1, except that the gelatin in this example is formulated into an aqueous solution at 5% by weight; the crosslinking agent is a carbodiimide solution, and the crosslinking reaction is carried out at 15° C. for 18 hours. The measurement results of dynamic fibrinolysis rate are shown in curve 1 and curve 2 of Fig. 3 .

[0071] Figure 3 dynamic fibrinolysis rate

[0072] Curve 1 is the dynamic fibrinolysis rate of simple urokinase.

[0073] Curve 2 is the dynamic fibrinolysis rate of carrier-urokinase complex.

[0074] It can be seen from the figure that the intravenous drug carrier material of this embodiment has a good controlled release effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com