Heat transfer intensification and automatic cleaning mechanism of natural circulation evaporator

A technology of automatic cleaning and heat transfer enhancement, which is applied to cleaning heat transfer devices, flushing, lighting and heating equipment, etc. It can solve the problems of low natural circulation flow rate, difficult promotion, frequent parking and cleaning, etc., and achieves convenient manufacturing, installation and maintenance Easy, simple structure and reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

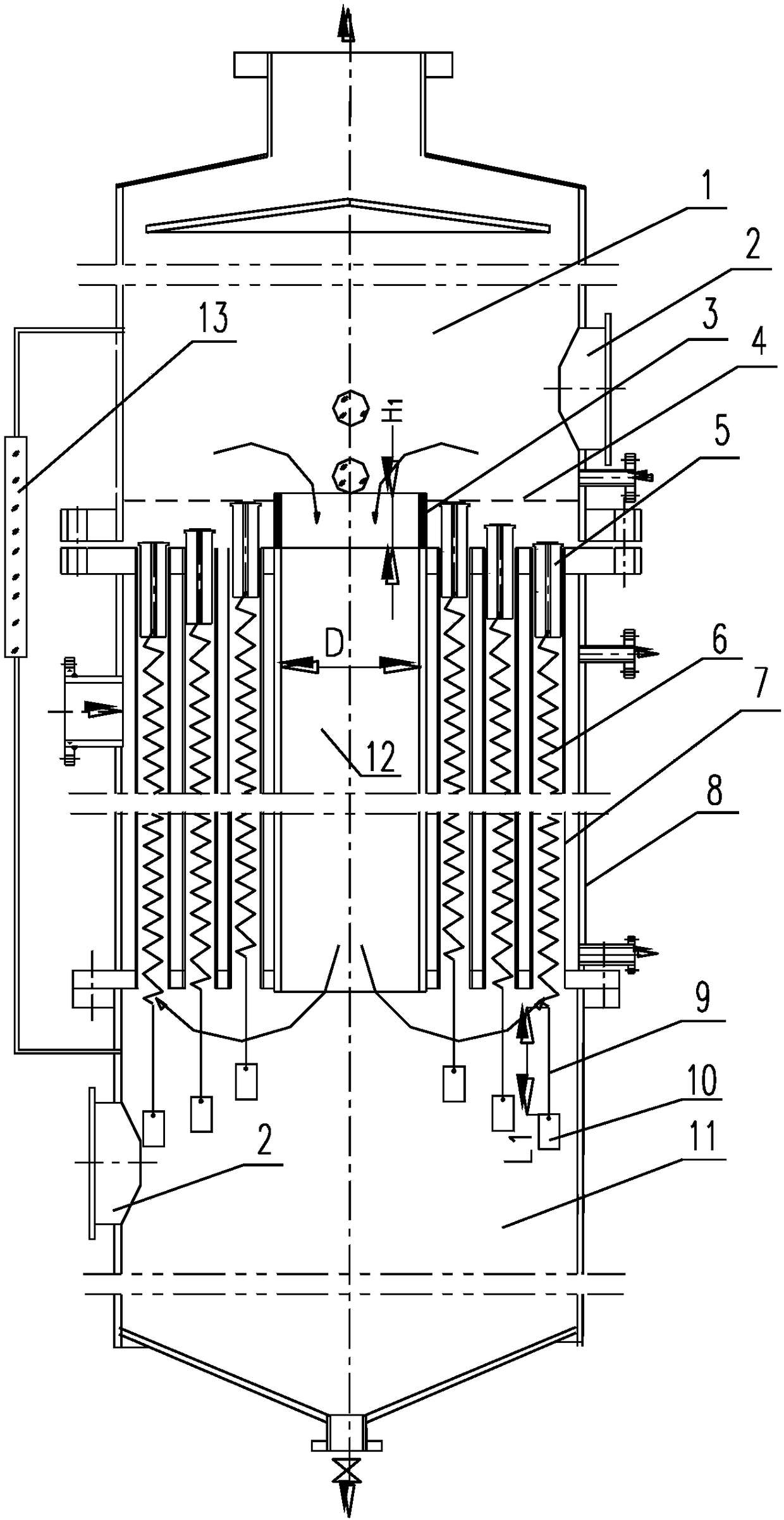

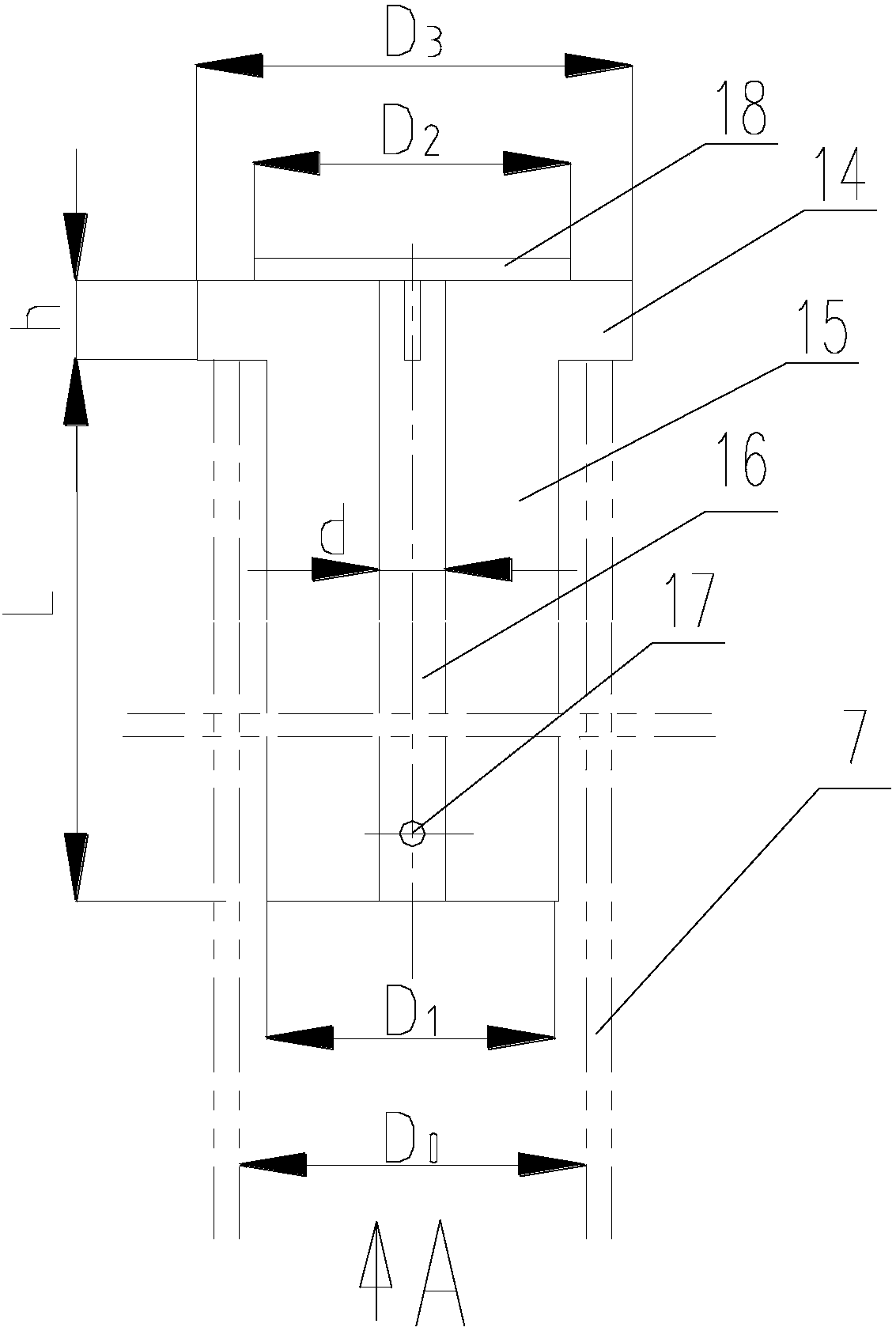

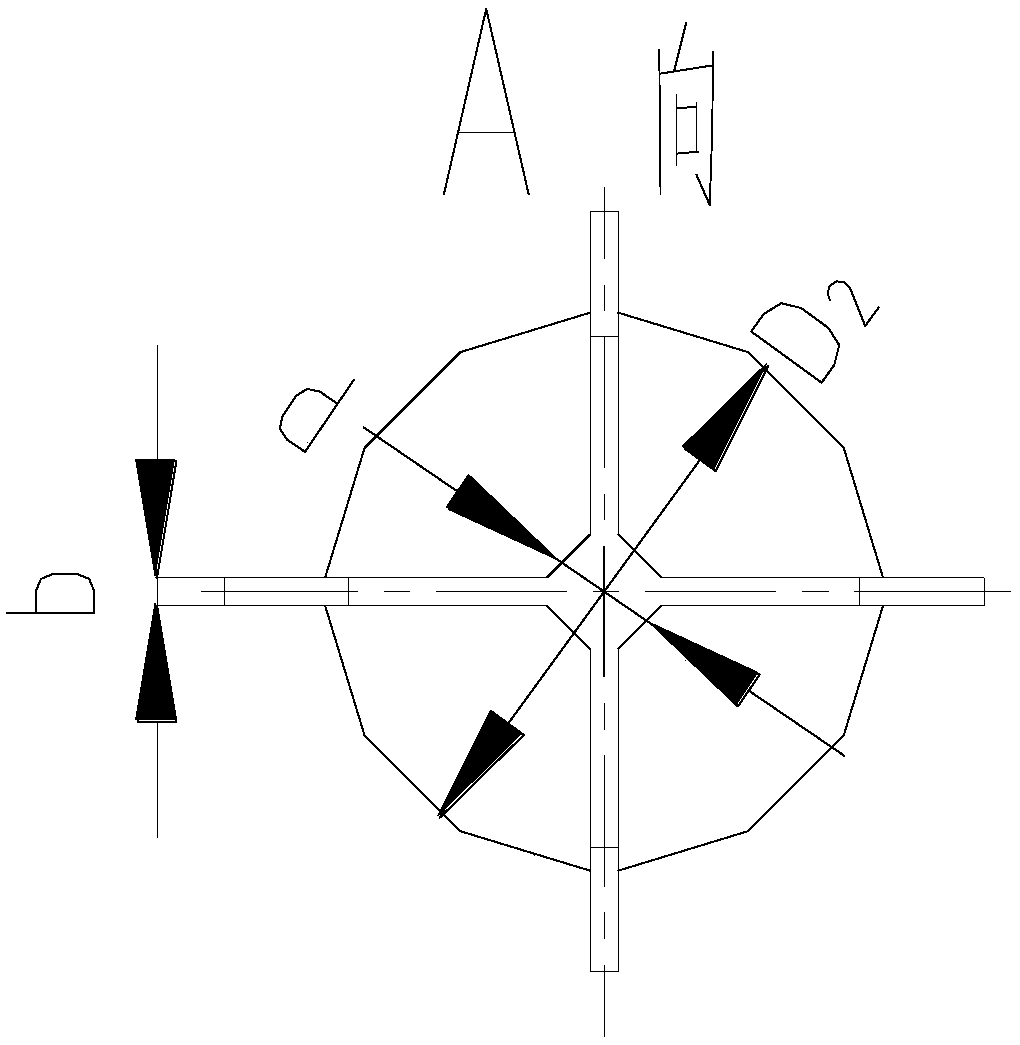

[0014] Attached below figure 1 , figure 2 , image 3 , the present invention is described in further detail.

[0015] In the figure, 1 evaporation chamber 2 manhole 3 top weir 4 limit screen 5 straight leaf disk 6 function spiral 7 heating pipe 8 heating chamber 9 straight section steel wire 10 hanging weight 11 bottom tank 12 central circulation pipe 13 communication pipe liquid level gauge 14 Hook shoulder 15 Straight leaf 16 Cylindrical shaft 17 Hanging hole 18 Impact plate

[0016] A heat transfer enhanced automatic cleaning mechanism for a natural circulation evaporator, the main structural components include an evaporation chamber 1, a heating pipe 7, a heating chamber 8, a bottom tank 11, a straight leaf disc 5, a functional spiral 6, and a hanging weight 10.

[0017] The natural circulation evaporator is at least composed of an evaporation chamber 1 , a central circulation pipe 12 , a heating chamber 8 and a bottom tank 11 . The heating tube 7 is equipped with a h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com