Novel horizontal pressure casting machine

A horizontal die-casting machine and a new type of technology, applied in the field of die-casting equipment, can solve the problems of oil pollution, poor working environment, high noise, etc., and achieve the effects of improving the working environment, saving energy and environmental protection, and having a simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described below in conjunction with specific embodiments.

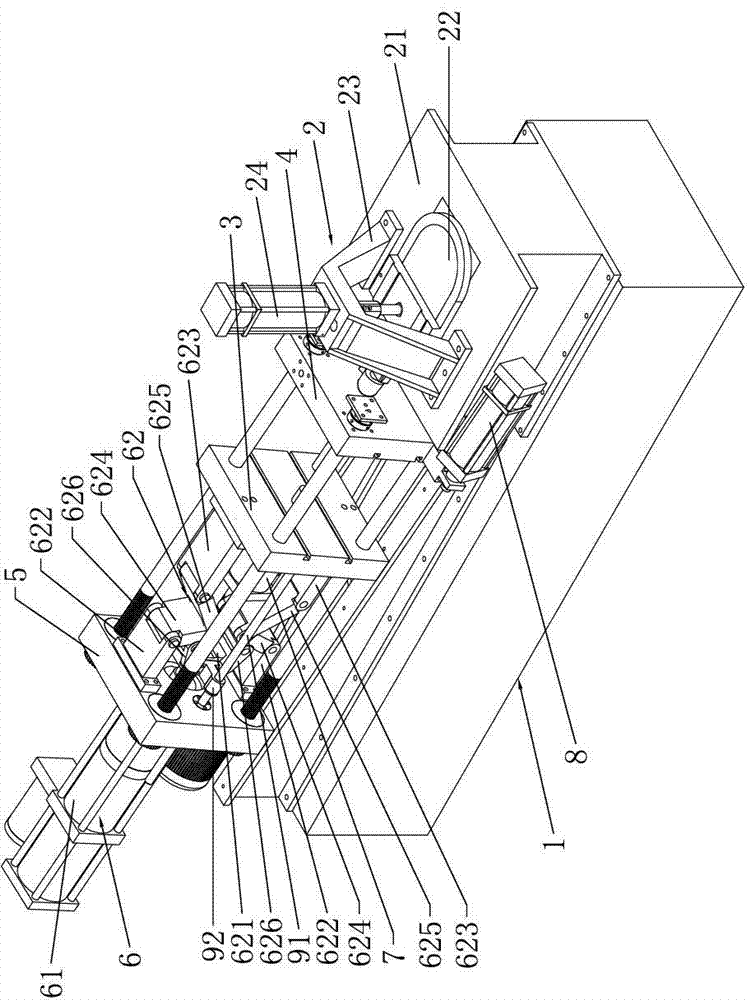

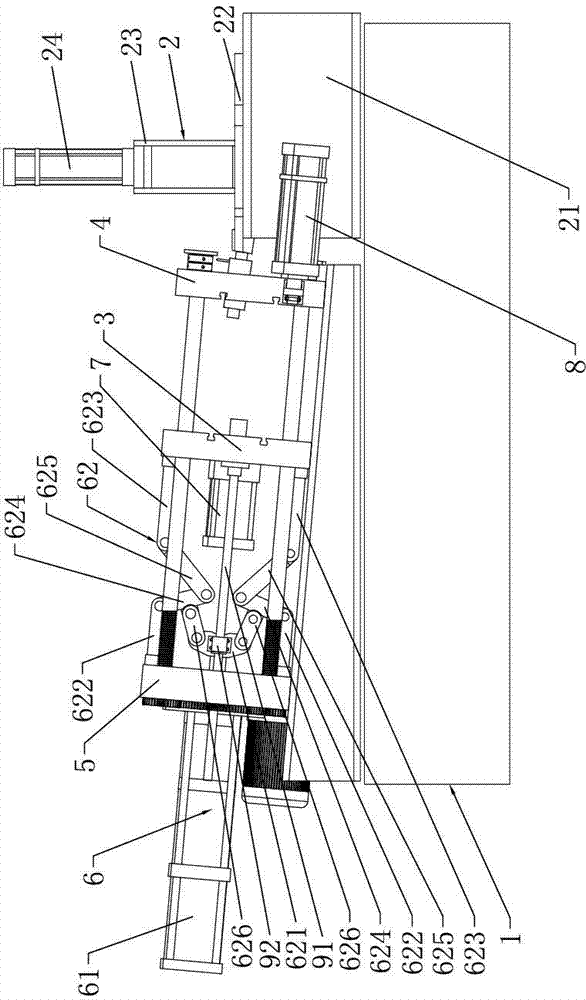

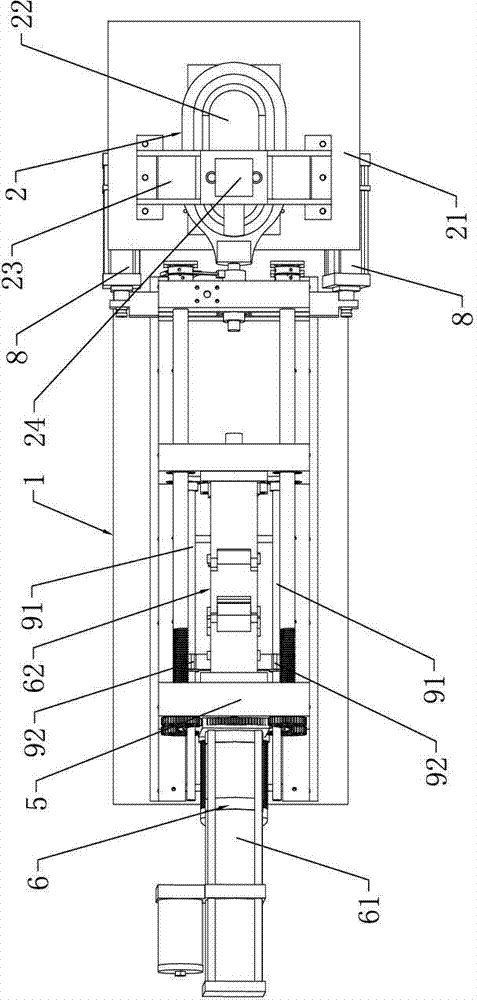

[0028] Such as Figure 1 to Figure 3 As shown, a new type of horizontal die-casting machine includes a frame 1, a feeding assembly 2 is installed above the right end of the frame 1, and the feeding assembly 2 includes a melting furnace 21 and a feeding pot installed in the melting furnace 21 22 and the pressurized cylinder support frame 23 installed above the melting furnace 21, the lower end of the melting furnace 21 is installed on the right end of the frame 1, and the pressurized support frame is equipped with a vertically moving material booster cylinder 24; the frame Above 1, on the left end side of the beating assembly 2, a movable seat plate 3 and a front seat plate 4 facing and arranged at intervals in parallel can be relatively movably installed. The front seat plate 4 is located at the right end side of the movable seat plate 3, and the frame Above 1, on the left end sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com