Ejector rod bottom rolling type bottom press device

A technology of rolling bottom and ejector, applied in the direction of containers, paper/cardboard containers, container manufacturing machinery, etc., can solve the problem that the bottom cover of square paper containers is not suitable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below in conjunction with accompanying drawing and embodiment the present invention is further described:

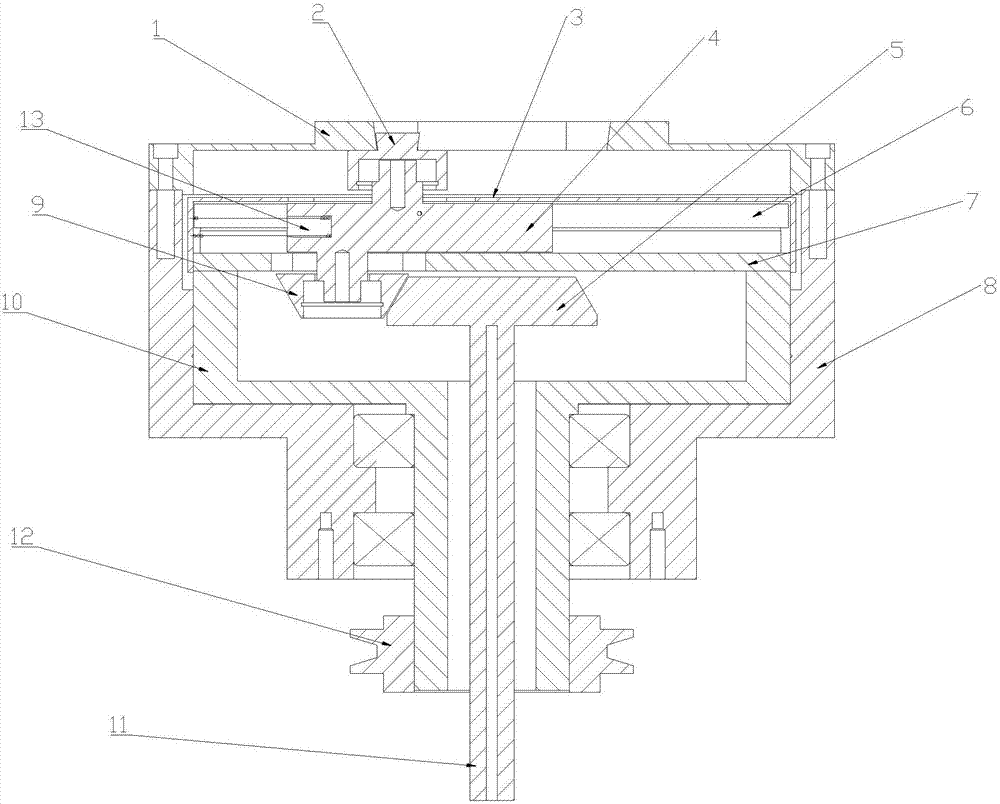

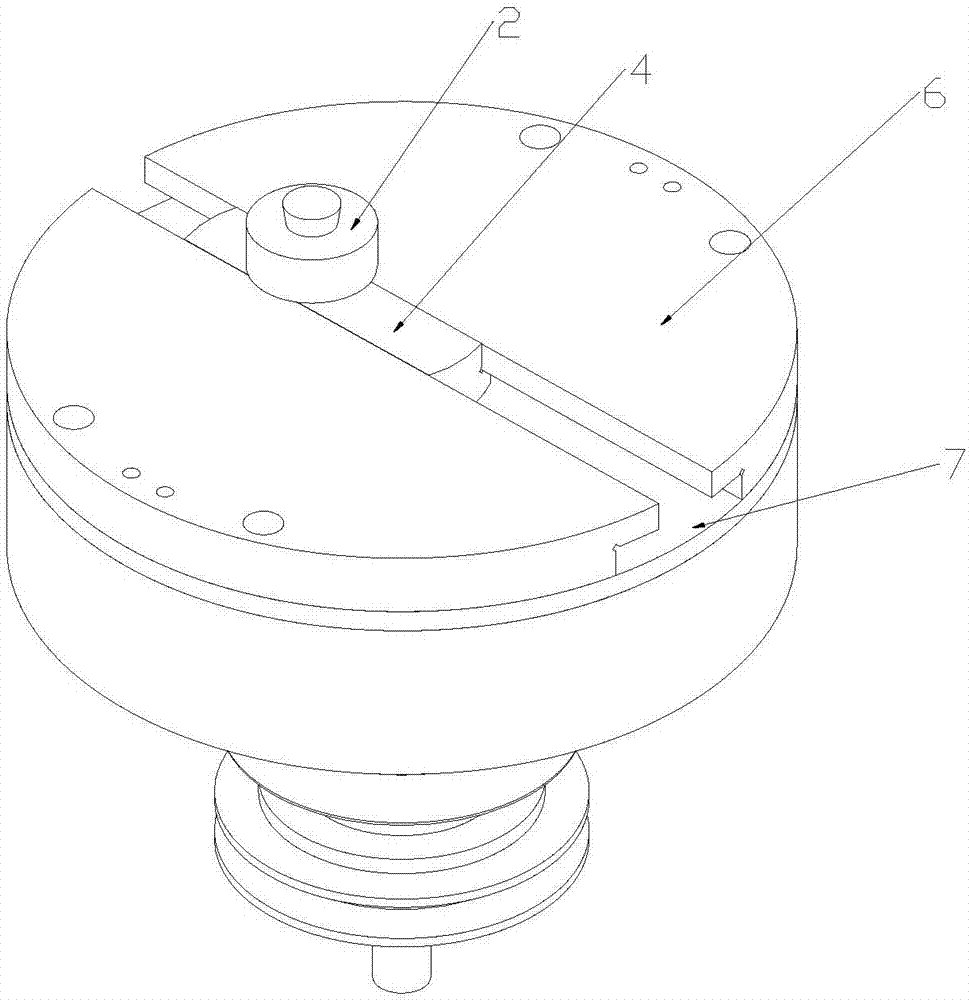

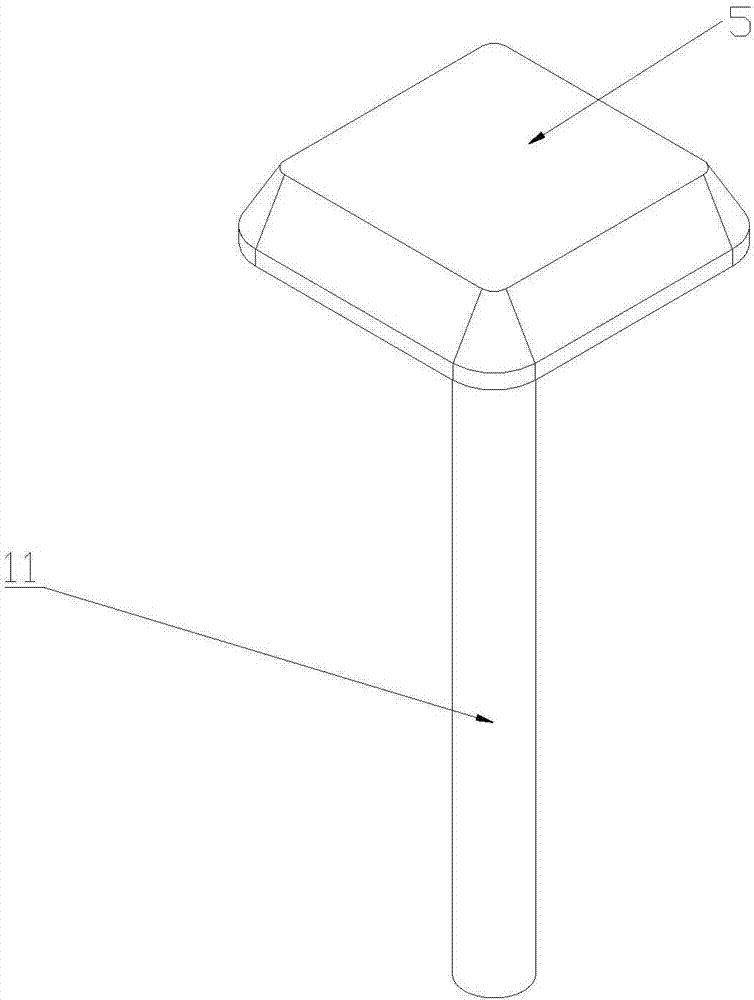

[0014] As shown in the figure, an embodiment of the push rod rolling bottom press of the present invention is provided, including a knurling outer mold 1, a knurling wheel 2, a lifting mechanism, a rotating mechanism, a rolling bottom outer mold base 8, and a slider base 10 , Ejector 11, described rolling bottom outer mold base 8 is arranged on the outside of slider base 10, described rolling bottom outer mold base 8 is provided with knurling outer mold 1, and described slider base 10 is provided with slider pad Plate 7, the slider backing plate 7 is provided with two outer sliders 6, the inner slider 4 is sandwiched between the two outer sliders 6, the inner slider 4 and the side of the slider seat 10 A spring 13 is provided between the walls, a knurling wheel 2 is provided on the upper side of the inner slider 4, and a thimble wheel 9 is provided on the lower si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com