Jacquard black-out cloth and production method thereof

A manufacturing method and technology of shading cloth, applied in the direction of digging fabrics, textiles, papermaking, fabrics, etc., can solve the problems of monotonous organizational structure and style, low fastness to washing and sunlight, flat and single surface, etc., and achieve convenient Promotion and application, low cost, soft hand feeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

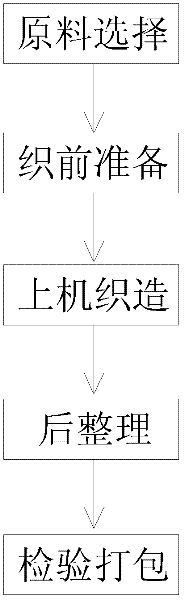

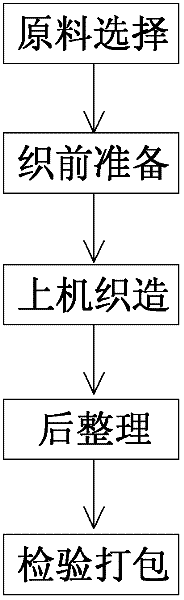

[0023] refer to figure 1 , the manufacture method of jacquard shade cloth, comprises the following steps successively:

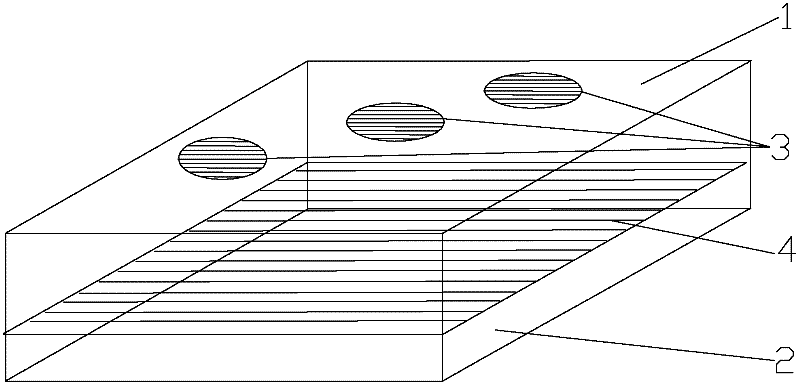

[0024] a) Selection of raw materials: 30D-600D polyester yarns are used for warp yarns, 100D-1000D polyester yarns are used for weft yarns, and the weft yarns have two or more colors; Dense, so when choosing the warp yarn, the finer the raw material, the better, but because the warp density is too high, the warp yarn is too fine to increase the breakage. In order to ensure normal weaving, 50D ~ 100D polyester filament is generally used to highlight the layering of jacquard patterns. , choose more than two kinds of weft yarns with different properties; the best choice is 75D / 288F polyester low-elasticity network yarn for warp yarns, and three sets of weft yarns of different colors for weft yarns. The first set of weft yarns is 300D / 96F black polyester low-elasticity yarns. The second set of weft yarns is 300D / 96F beige polyester low elastic yarn, and the thi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com