Inkjet transfer printing and dyeing paper used for nylon-containing fabrics, and making method and use method thereof

A nylon fabric, transfer printing and dyeing technology, applied in the field of printing and dyeing, can solve the problems of low pass rate of printing and dyeing, prone to color difference, cumbersome process, etc., achieve bright color, simplify production process, and improve the effect of pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

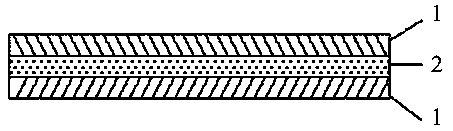

Image

Examples

preparation example Construction

[0034] The following introduces a specific embodiment of the preparation method of the inkjet transfer printing and dyeing paper used for nylon fabrics of the present invention. In this embodiment, the method includes the following steps:

[0035] Provide the substrate;

[0036] The functional material is coated on the substrate to form a functional coating covering the substrate.

Embodiment 1

[0039] Configure functional material water-based glue, which contains 5% sodium alginate, 5% polyvinyl alcohol, 2% sodium carboxymethyl cellulose, 1% sodium polyacrylate, 2% maleic acid, 2% % of glacial acetic acid, 1% of polyurethane, 0.5% of silicon dioxide; a layer of functional material is coated on the base paper of 75g / m2, and after drying, it is made into the spray coating for nylon-containing fabric described in this embodiment. Ink transfer dyed paper.

[0040] The method of using the above-mentioned printing and dyeing paper is as follows: load the dye ink in the inkjet printer, and print the color pattern in a mirror image on the functional coating for the digital printing and dyeing paper containing nylon fabric described in this embodiment; For nylon fabrics, use a flat heat press at a temperature of 100°C and 10kg / cm 2 Heat pressing under high pressure for 30 seconds; then put the nylon fabric bonded by the printing and dyeing paper in a steamer, steam at 105°C...

Embodiment 2

[0042] Configure functional material water-based glue, which contains 5% sodium alginate, 5% polyvinyl alcohol, 2% sodium carboxymethyl cellulose, 1% sodium polyacrylate, 2% maleic acid, 2% % of glacial acetic acid, 1% of polyurethane, 0.5% of silicon dioxide; a layer of functional material is coated on the base paper of 100g / m2, and after drying, it is made into the spray coating for nylon-containing fabric described in this embodiment. Ink transfer dyed paper.

[0043] The method of using the above-mentioned printing and dyeing paper is as follows: load the dye ink in the inkjet printer, and print the color pattern in a mirror image on the functional coating for the digital printing and dyeing paper containing nylon fabric described in this embodiment; For nylon-wool blended fabrics, use a flat-bed heat press at a temperature of 100°C and a pressure of 10kg / cm2 for 30 seconds; Steam for 15 minutes, then peel the printed paper from the nylon wool blend to complete the transf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com