Air bag with gas blocking sealant at sewn seams

A technology of airbags and sealants, which is applied in vehicle safety arrangements, pedestrian/passenger safety arrangements, vehicle components, etc., can solve expensive and difficult-to-implement problems, and achieve the effect of preventing gas leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

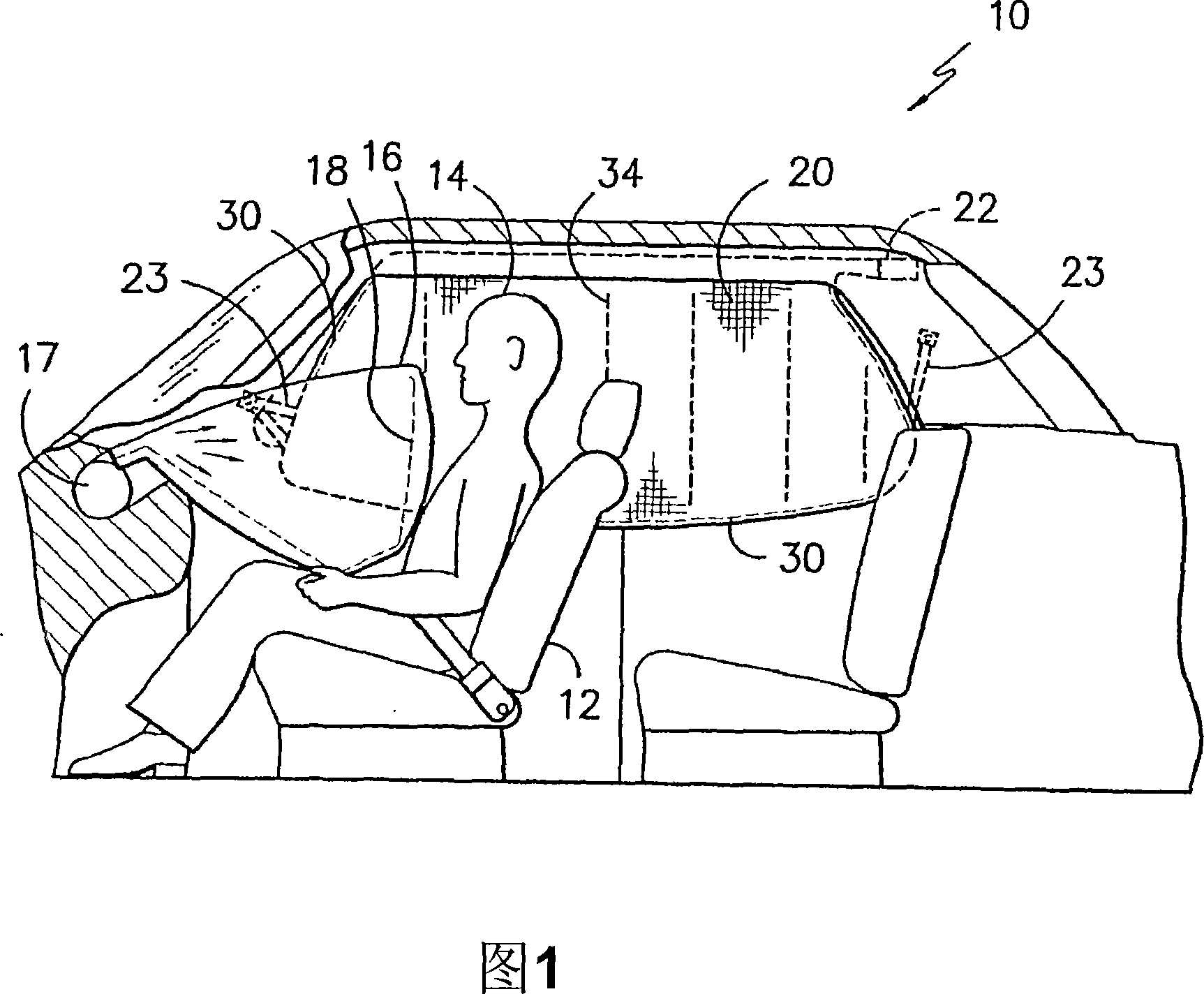

[0011] Referring now to the drawings, in which like parts in the different views are labeled with like legend numerals. Returning to FIG. 1 , the internal structure of the delivery vehicle 10 is shown. It is to be understood that the transportation vehicle may have various configurations, such as an automobile, truck, van, sport utility vehicle, or the like. Regardless of the actual vehicle configuration, one or more rows of seats 12 will be included to support passengers 14 .

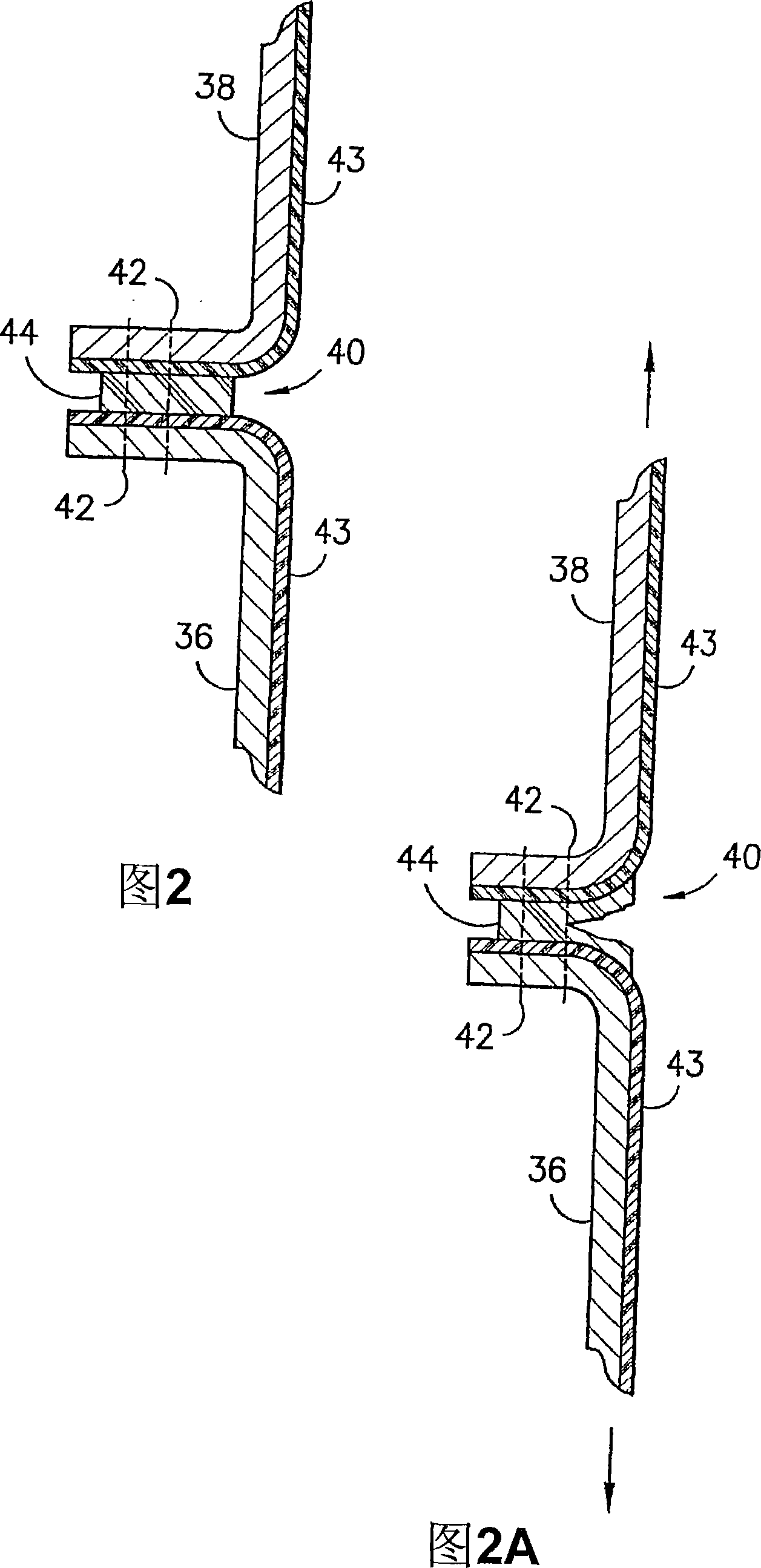

[0012] As shown, the vehicle 10 includes an impact absorbing airbag 16 that is used with an inflator 17 to rapidly deploy toward the occupants. Impact absorbing airbag 16 may be formed from one or more blanks, such as fabric or the like, joined together along seam 18 . According to the present invention, at least part of the seam 18 may be a seam seam formed by passing sewing thread through a stitch arrangement between opposing sheets of material. Of course, it is to be understood that the illustrat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| coating mass | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com