Double-motor mechanical coordination in-phase slider driven eight-bar servo pressure device

A servo press and double motor technology, applied in the field of servo-driven mechanical presses in mechanical engineering, can solve the problems of high manufacturing and installation accuracy requirements, low transmission efficiency, serious heat generation, etc., and achieve large tonnage stamping processing, low cost, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

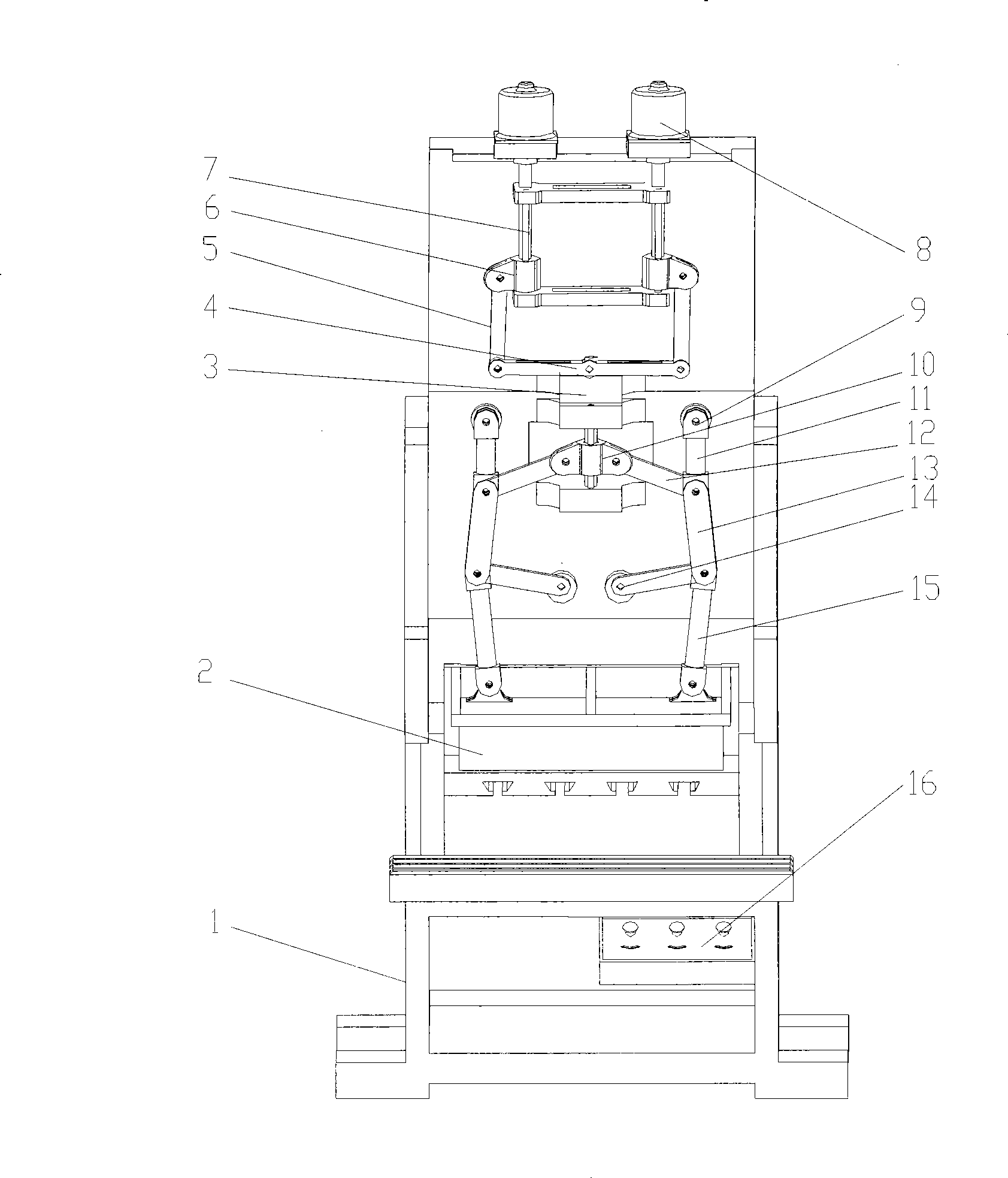

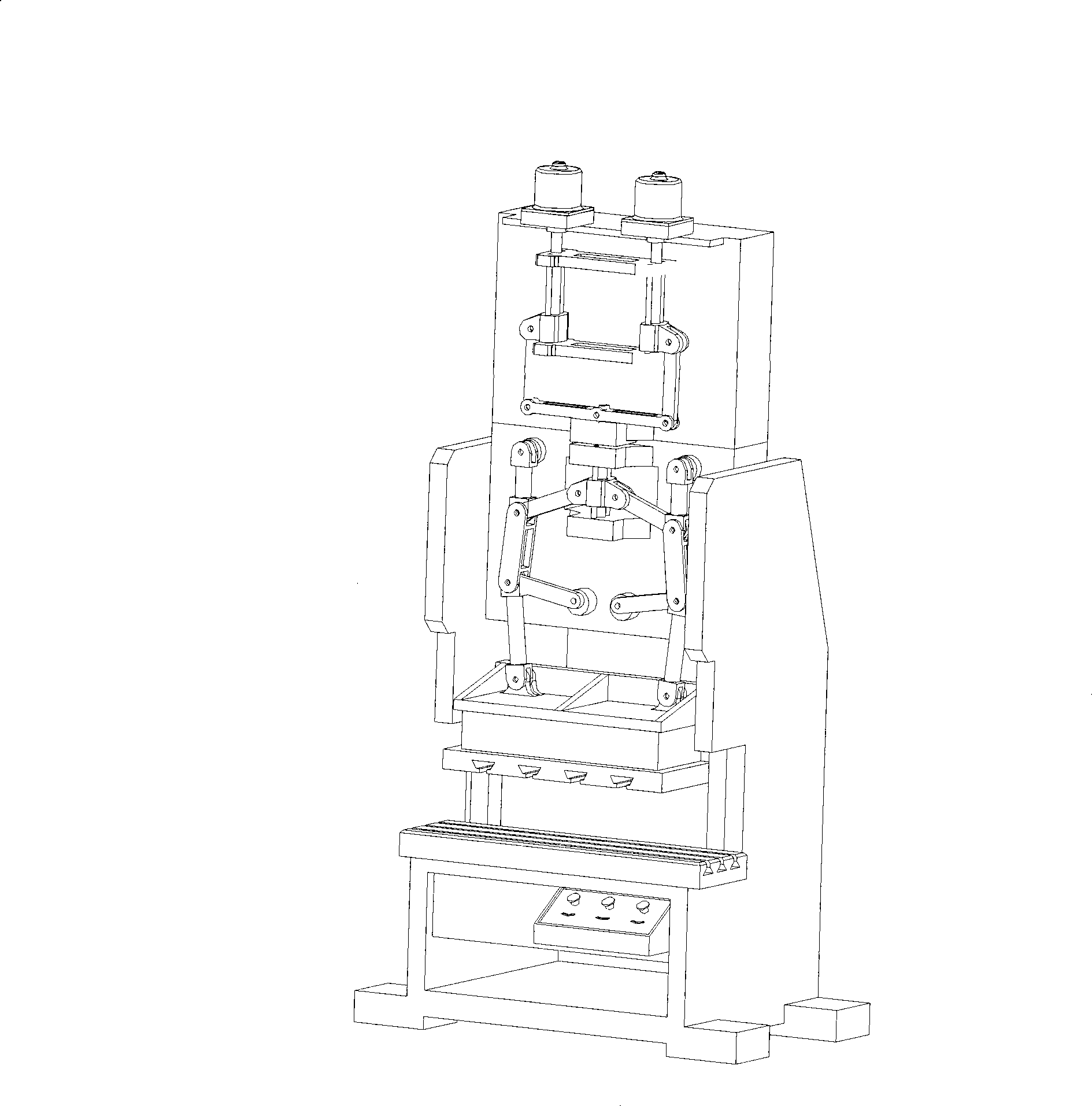

[0017] figure 1 It is a schematic diagram of the overall structure of the present invention.

[0018] Such as figure 1 As shown, the dual-motor mechanical coordination synchronous slider-driven eight-bar servo press designed by the present invention includes a servo motor 8, a driving slider 10, a stamping slider 2, a frame 1 and an operation box 16, and two symmetrically arranged servo presses. The motor 8 is connected to the driving slider 10 through a set of dual-motor mechanically coordinated synchronous slider driving mechanism, and the driving slider 10 is connected to the stamping slider 2 through two sets of left-right symmetrically arranged eight-linkage stamping mechanisms.

[0019] The dual-motor mechanically coordinated synchronous slider drive mechanism includes two lead screws 7, two movable nuts 6, two small connecting rods 5,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com