Mobile grinding machine for repair of taper hole of machine tool spindle

A machine tool spindle and mobile technology, applied to grinding machines, machine tools designed for grinding the rotating surface of workpieces, grinding/polishing equipment, etc., can solve the problems of no way to guarantee the accuracy of the spindle, high maintenance costs, and long maintenance cycles. Achieve the effects of precise adjustment of rotation angle, low manufacturing cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

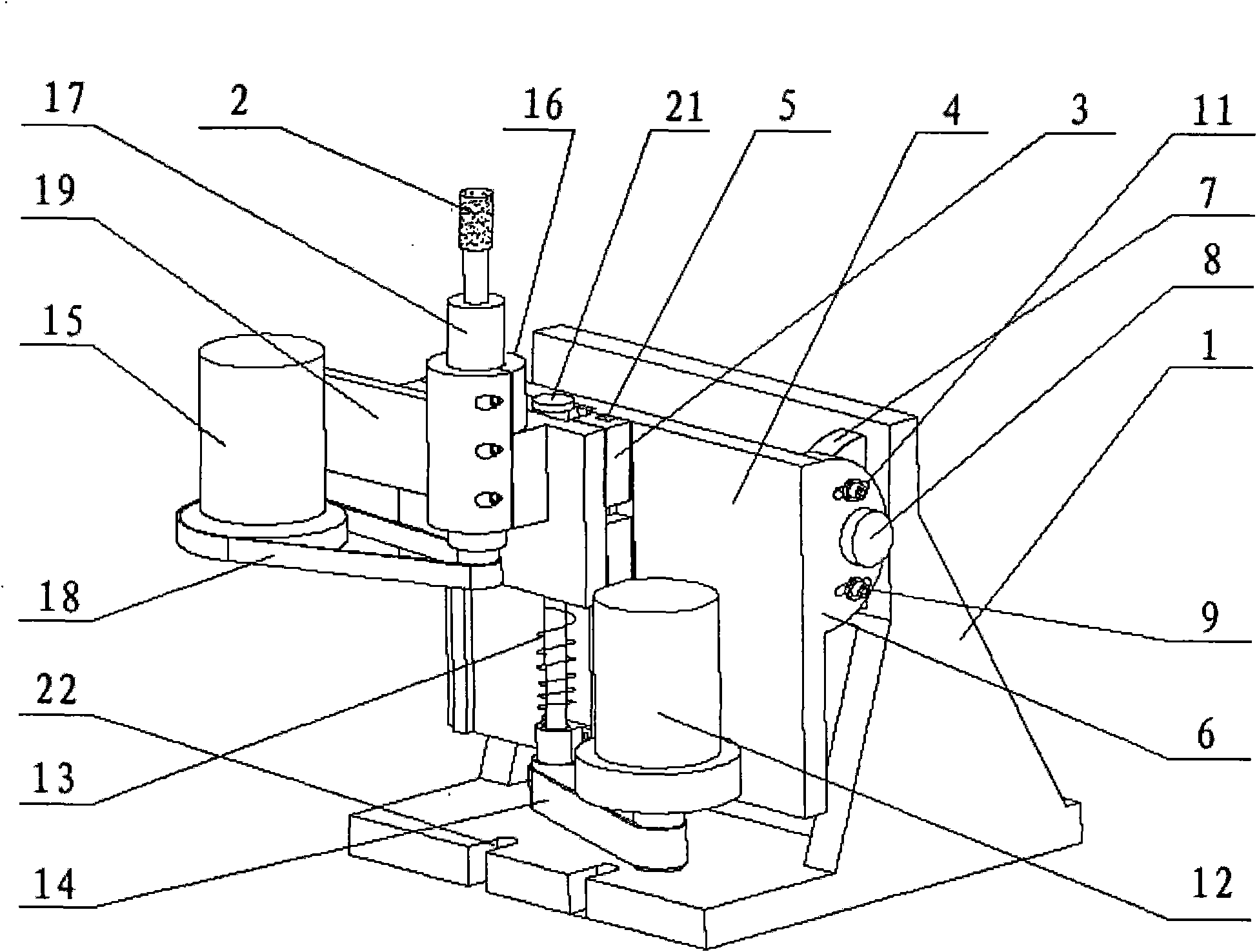

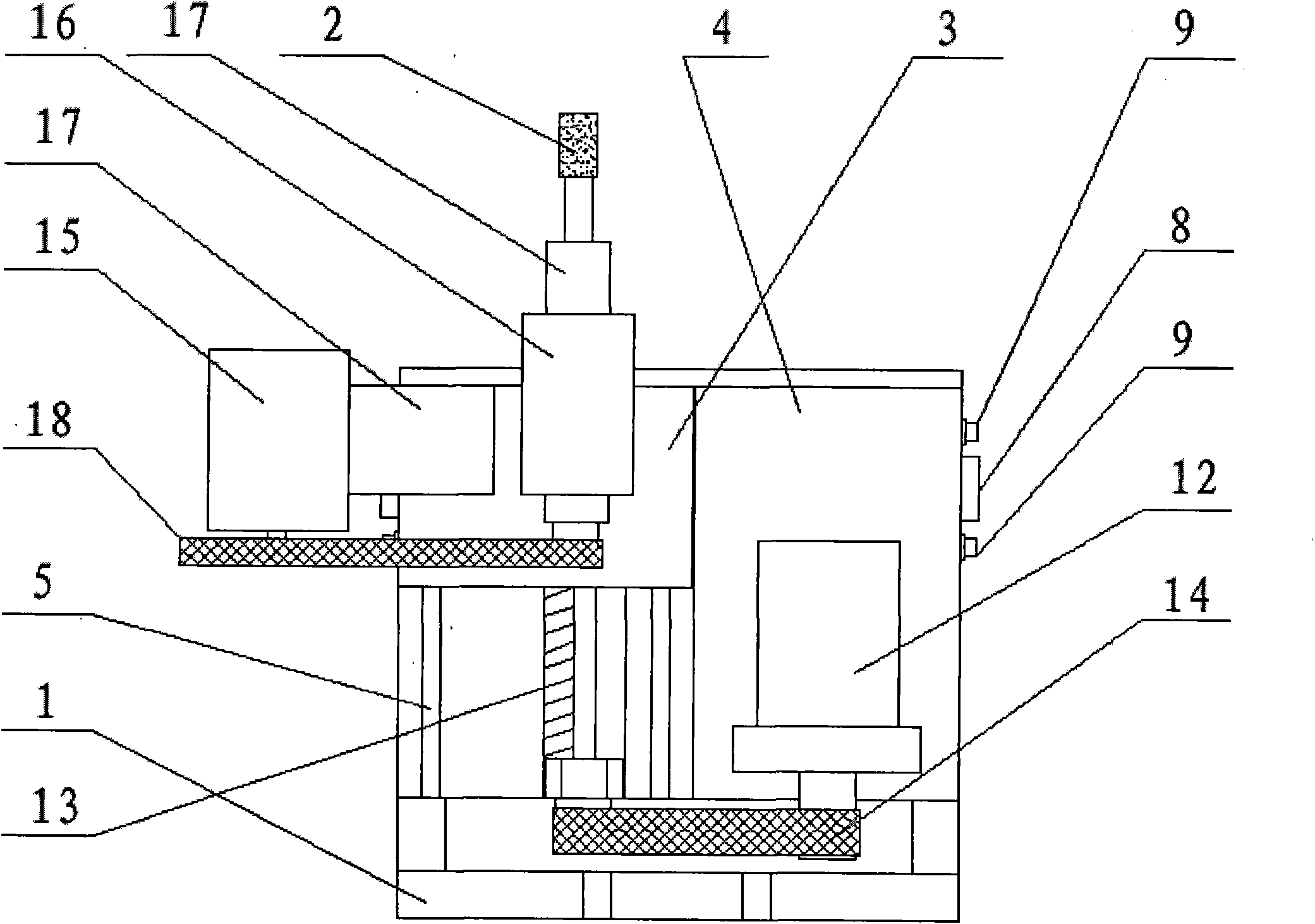

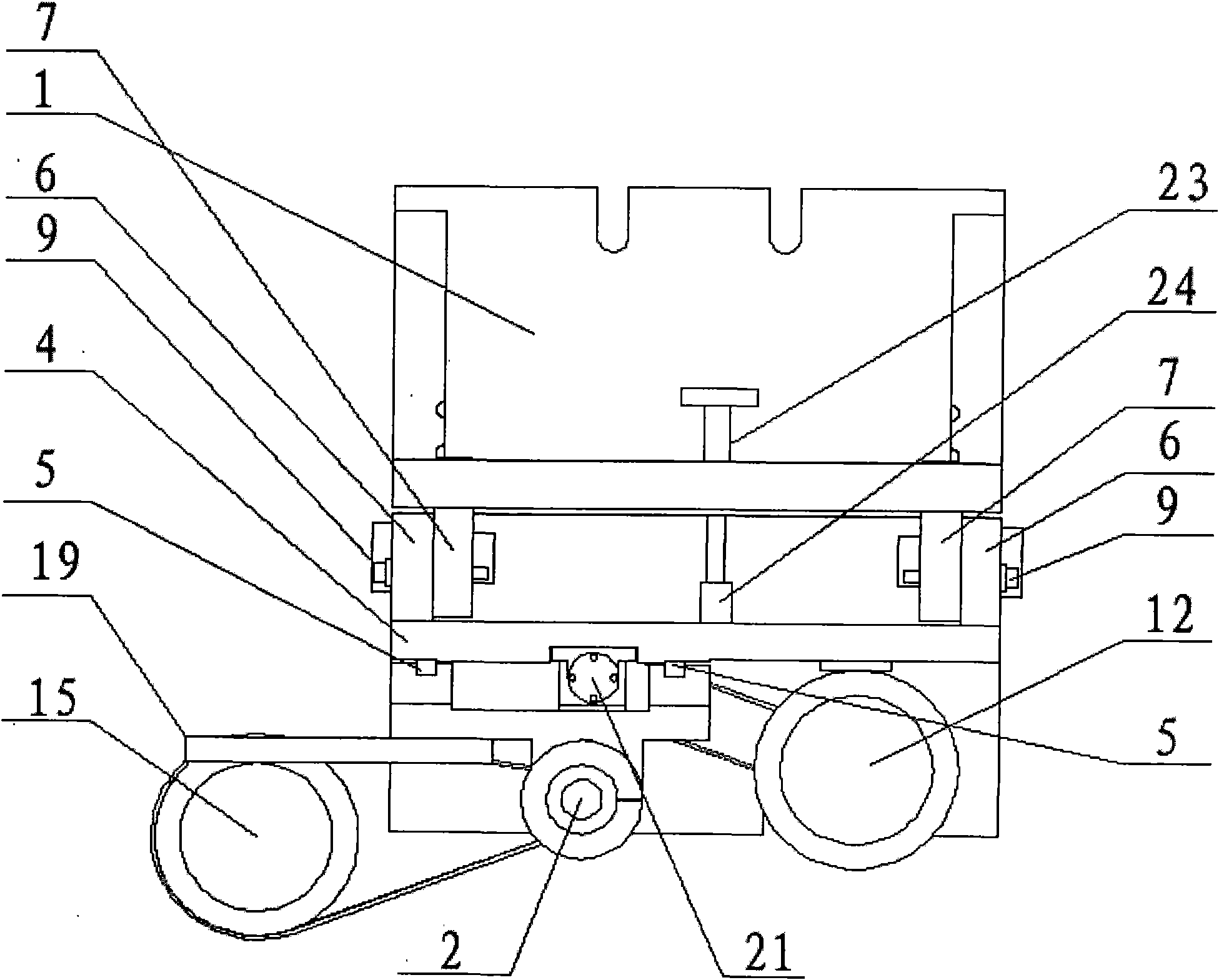

[0033] The design concept of the present invention is to add an angle adjusting device to make the grinding head have the same angle as the taper of the machine tool spindle to be repaired, and then realize the grinding and repairing of the taper hole through the feed of the grinding head along the angle. The design concept of the present invention will be further described in detail below in conjunction with the specific structure description.

[0034] by Figure 1-Figure 5 It can be seen that the mobile machine tool spindle taper hole repair grinder of the present invention includes a base 1, a grinding head 2, a grinding head rotation driving device that fixes the grinding machine on a worktable surface 20, and the grinding head 2 and the grinding head rotation driving device pass through and The two fixed sliding blocks 3 and the supporting plate 4 are connected in cooperation. The horizontal support surface of the base 1 is provided with a connecting half hole 22 connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com