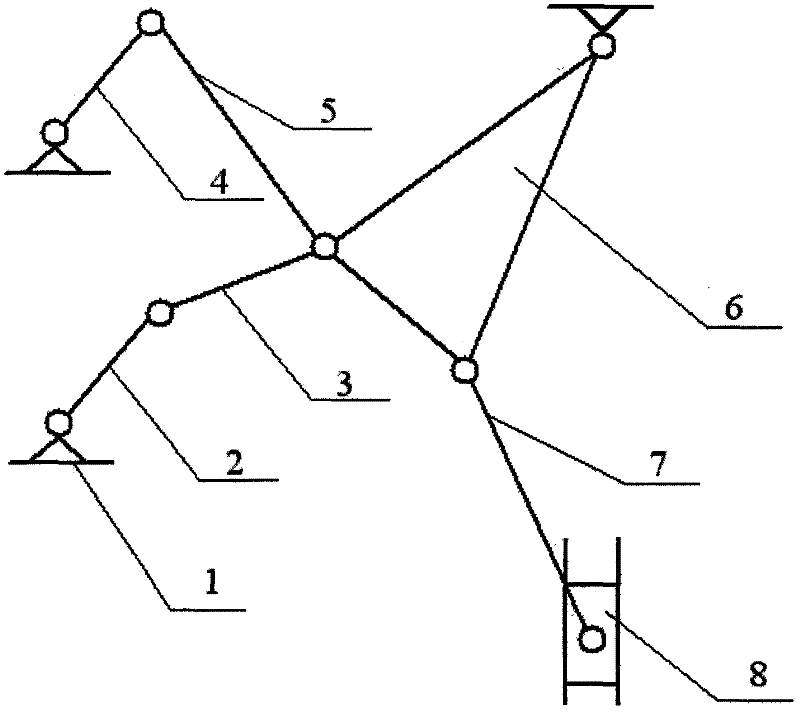

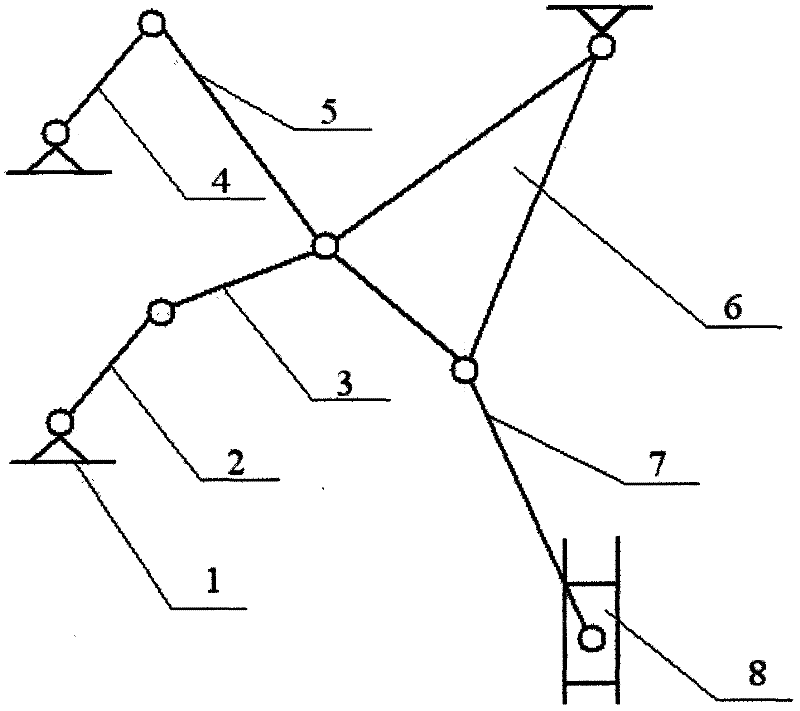

Eight-bar servo press with triangular pendulum

A technology of servo press and triangular pendulum, which is applied in the field of mechanical presses, can solve the problems of poor flexibility, low forming quality, and low quality of stamping forming, and solve the problems of poor flexibility, good force transmission characteristics, and various pressure working curves effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0007] Such as figure 1 The specific embodiment of the present invention shown is an eight-bar servo press with a triangular pendulum. The press includes a frame 1, a first crank 2, a second crank 4, a first connecting rod 3, a second crank Two connecting rods 5, a triangular pendulum 6, a hammer connecting rod 7 and a hammer 8, the first crank 2 and the second crank 4 are respectively connected with the frame 1 through a rotating pair; the first crank 2 is connected with the servo motor, and The first crank 2 is driven to rotate by the servo motor; the first connecting rod 3 is connected with the first crank 2 through a rotating pair, the second connecting rod 5 is connected with the second crank 4 through a rotating pair, the first connecting rod 3, the second The connecting rod 5 and the triangular pendulum 6 are connected at the same point through the rotating pair; the triangular pendulum 6 is respectively connected with the frame 1 and the hammer connecting rod 7 through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com