Cam rotors for cam rotor vane hydraulic servomotors

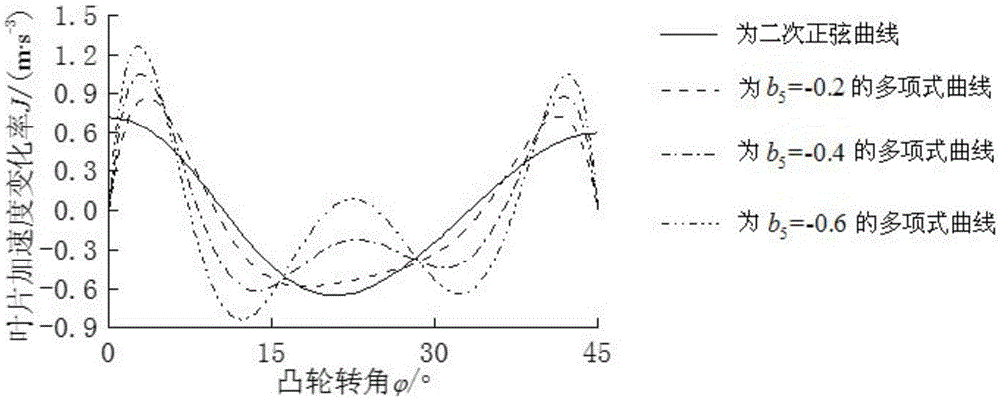

A cam rotor and hydraulic servo technology, which is applied in the field of servo motors, can solve the problems of unstable motor output torque, unstable radial motion of blades, sudden changes in acceleration, etc., and achieve small torque ripple, good servo performance, and stable operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The following is a detailed description of the embodiments of the present invention: this embodiment is implemented on the premise of the technical solution of the present invention, and provides detailed implementation methods and specific operation processes. It should be noted that those skilled in the art can make several modifications and improvements without departing from the concept of the present invention, and these all belong to the protection scope of the present invention.

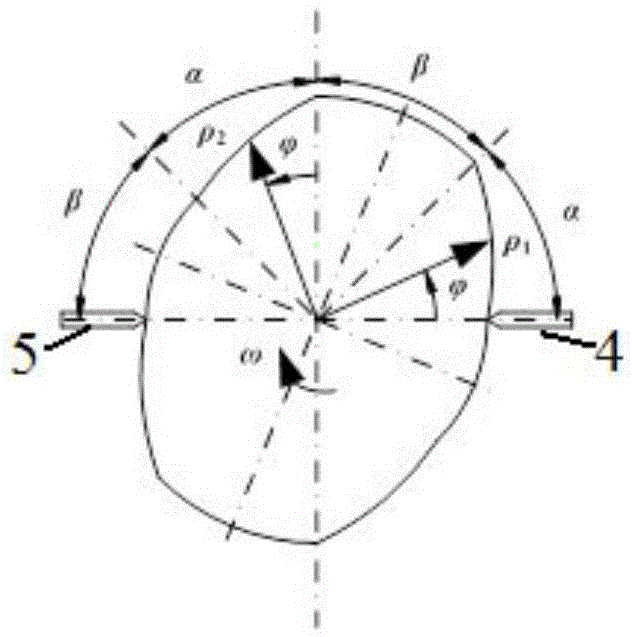

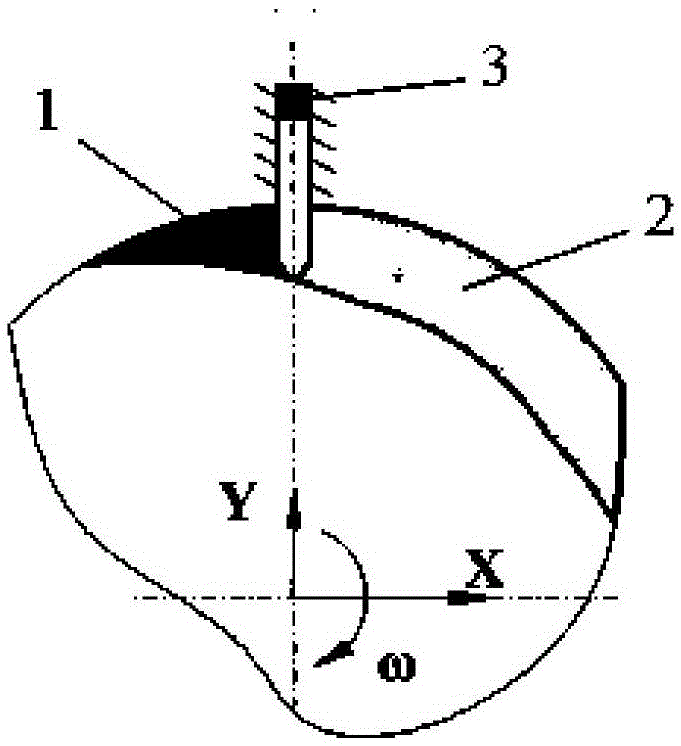

[0024] This embodiment provides a cam rotor for a cam rotor vane hydraulic servo motor, including a cam, the cam includes a cam major diameter R, a cam minor diameter r, and a transition curve between the cam major diameter and the cam minor diameter, the The transition curve between the cam major diameter and the cam minor diameter of the cam is a polynomial curve cluster, and its mathematical expression is:

[0025]

[0026] In the formula, is the transition curve with the small ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com