Hydraulic control apparatus for internal mixer

A technology of control device and internal mixer, which is applied to fluid pressure actuating devices, presses, manufacturing tools, etc., can solve the problems of large jitter, large impact, and oil leakage of superimposed valve blocks, so as to simplify hydraulic control. equipment, improve the quality of rubber mixing, and solve the effect of high failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

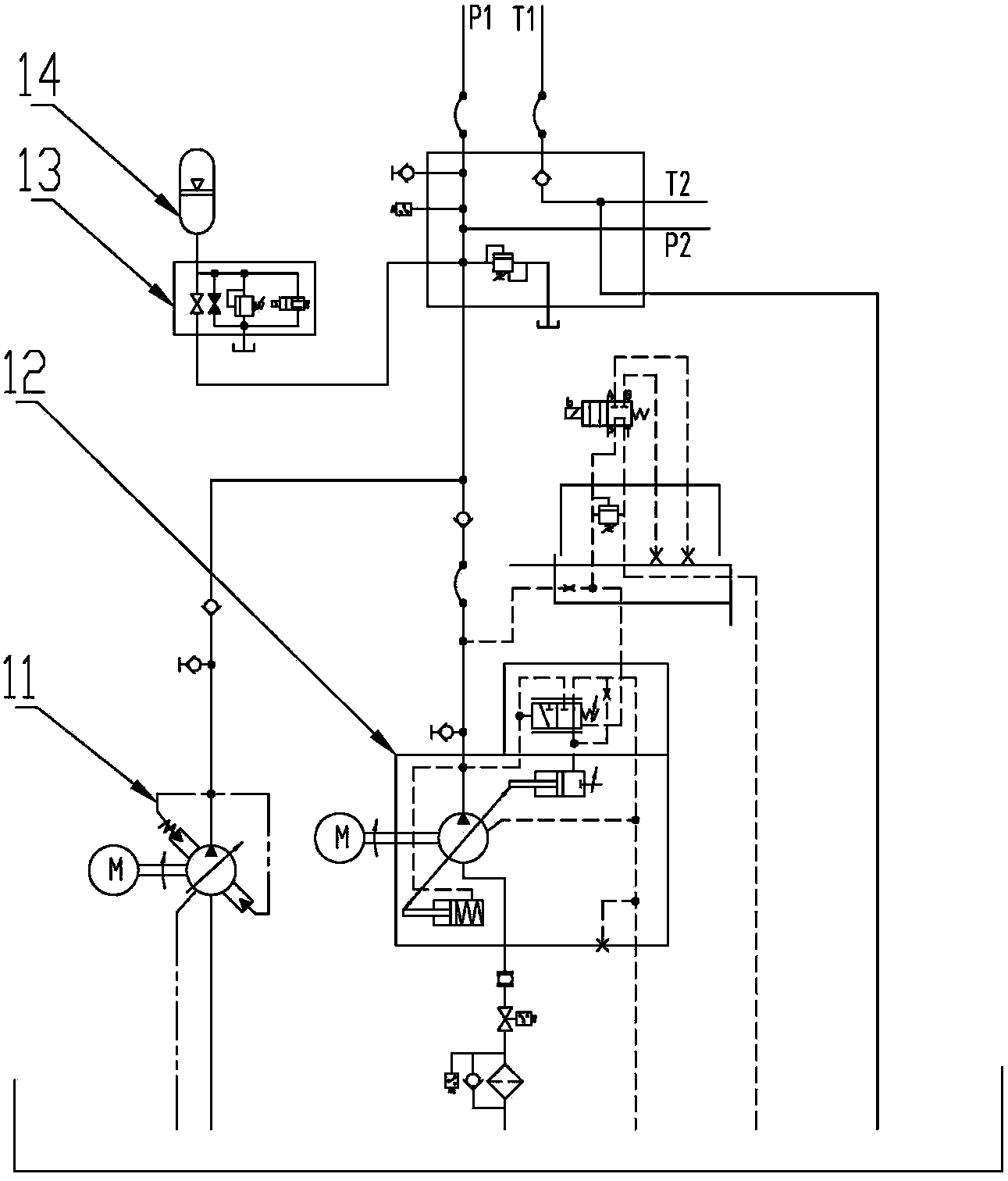

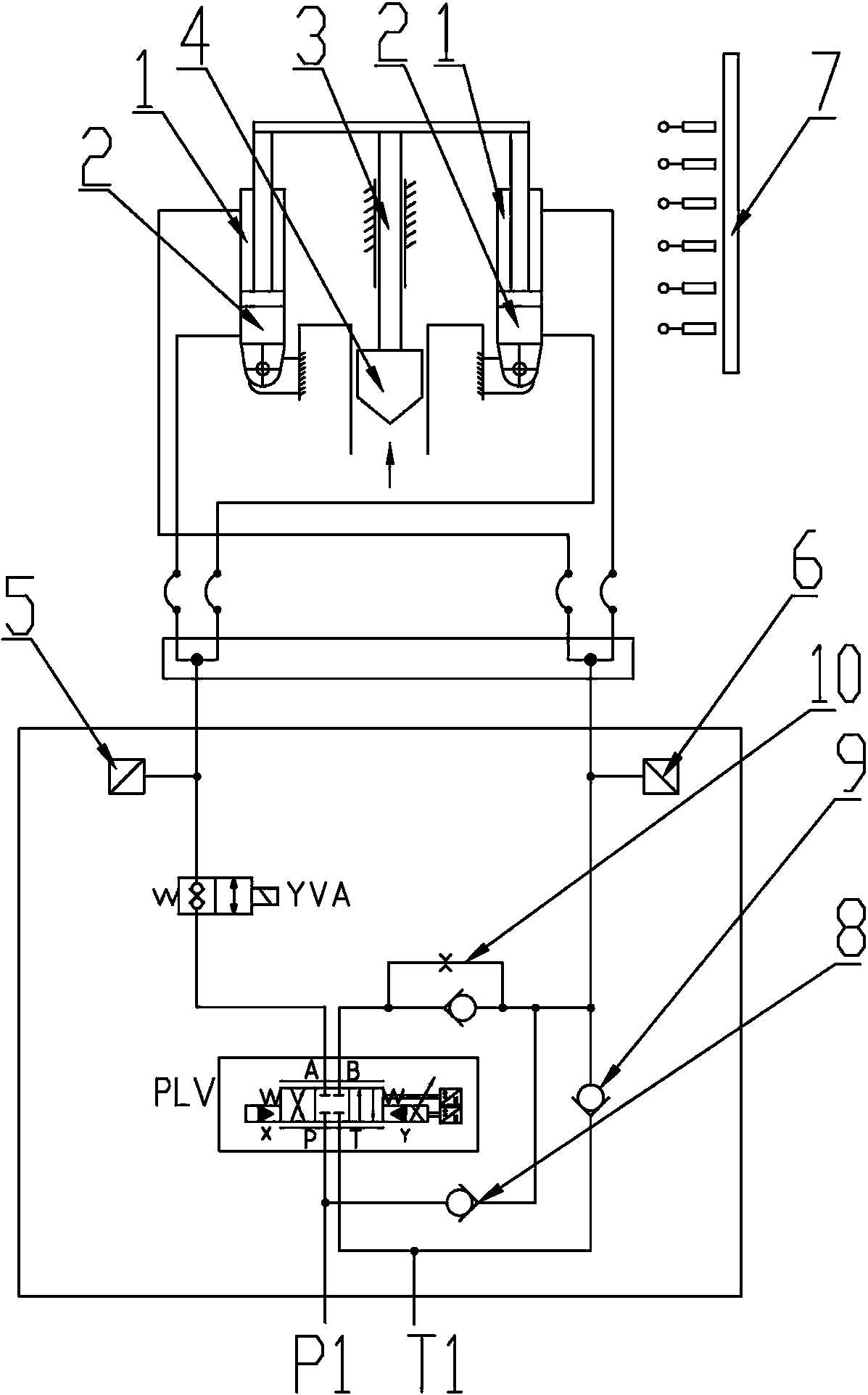

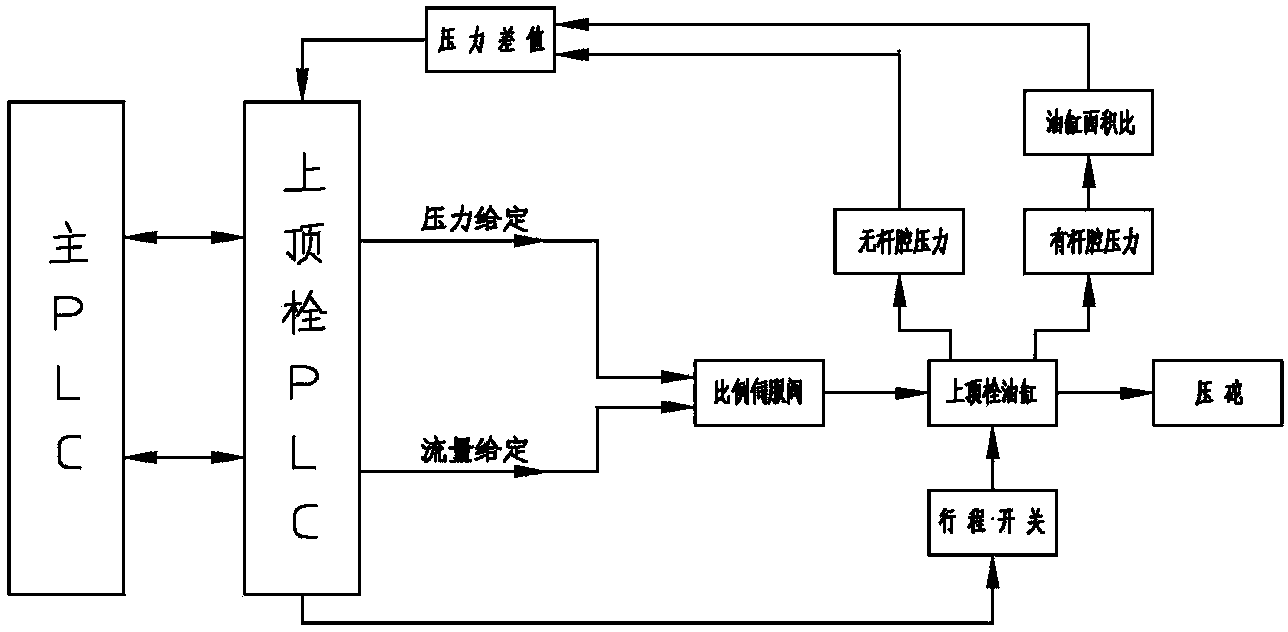

[0021] Depend on figure 1 It can be seen that at present, the feeding and pressing device and unloading device of the internal mixer often adopt hydraulic control mode, and the existing hydraulic pump stations are all driven by high-pressure variable-variable plunger pump 12 and high-pressure small-variable plunger pump 11 with remote setting Including the action of all oil cylinders such as the top bolt cylinder and the rotary cylinder. Through the computer (main PLC) control of the internal mixer, the combination of the high-pressure variable plunger pump 12, the accumulator safety valve block 13, and the accumulator 14 can accurately and reliably complete the lifting, lowering and pressurization of the upper jackbolt ; Another part of the pressure oil produced by the high-pressure variable plunger pump 12 enters the auxiliary control part to complet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com