Direct connection heating self-compressing unit for high-rise building

A technology for high-rise buildings and heating units, used in hot water central heating systems, household heating, heating methods, etc., can solve the problem of high-area backwater potential energy consumption, failure to meet energy-saving requirements, and insufficient use of high-area backwater pressure, etc. problem, to achieve the effect of low cost, easy popularization and easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

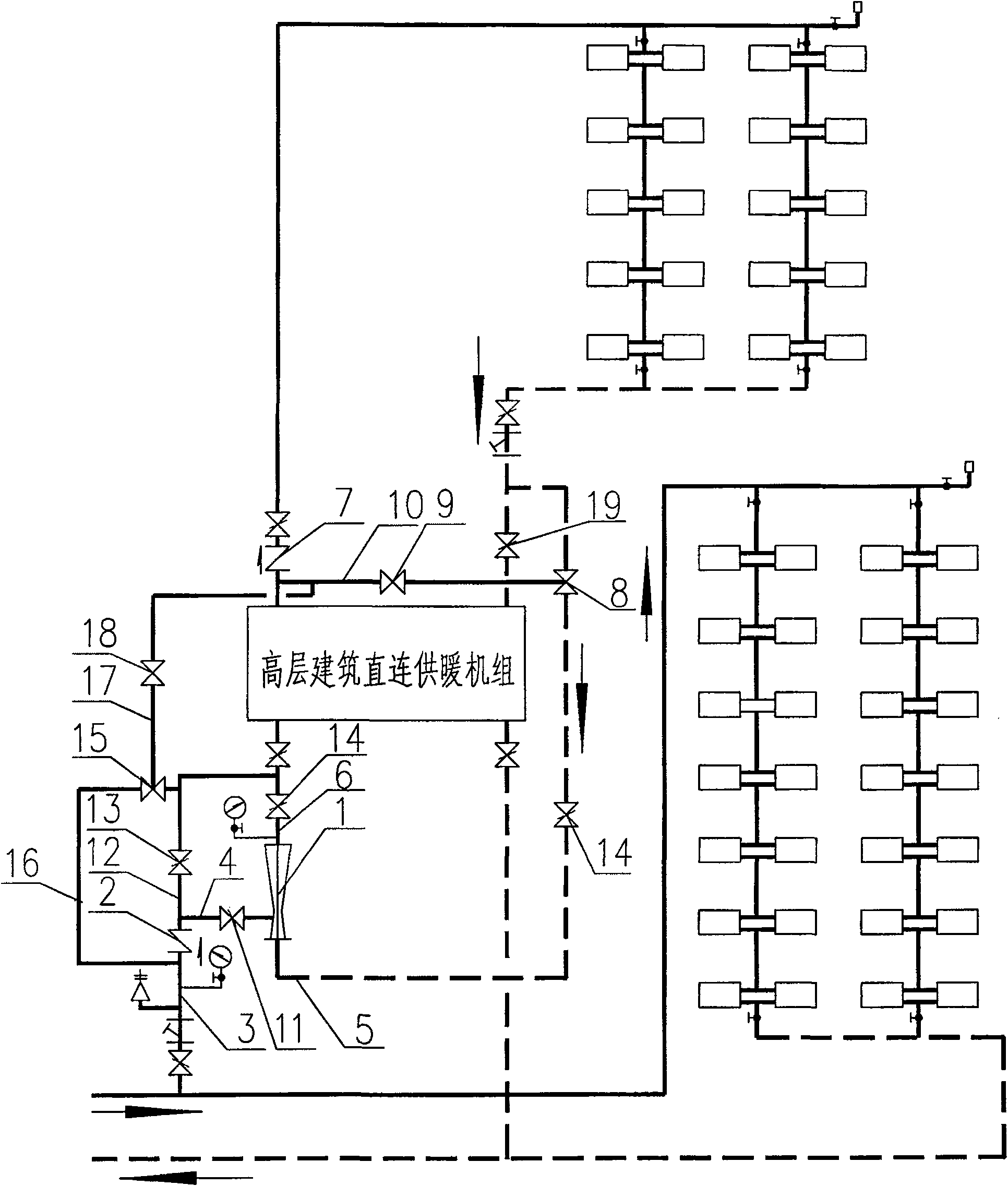

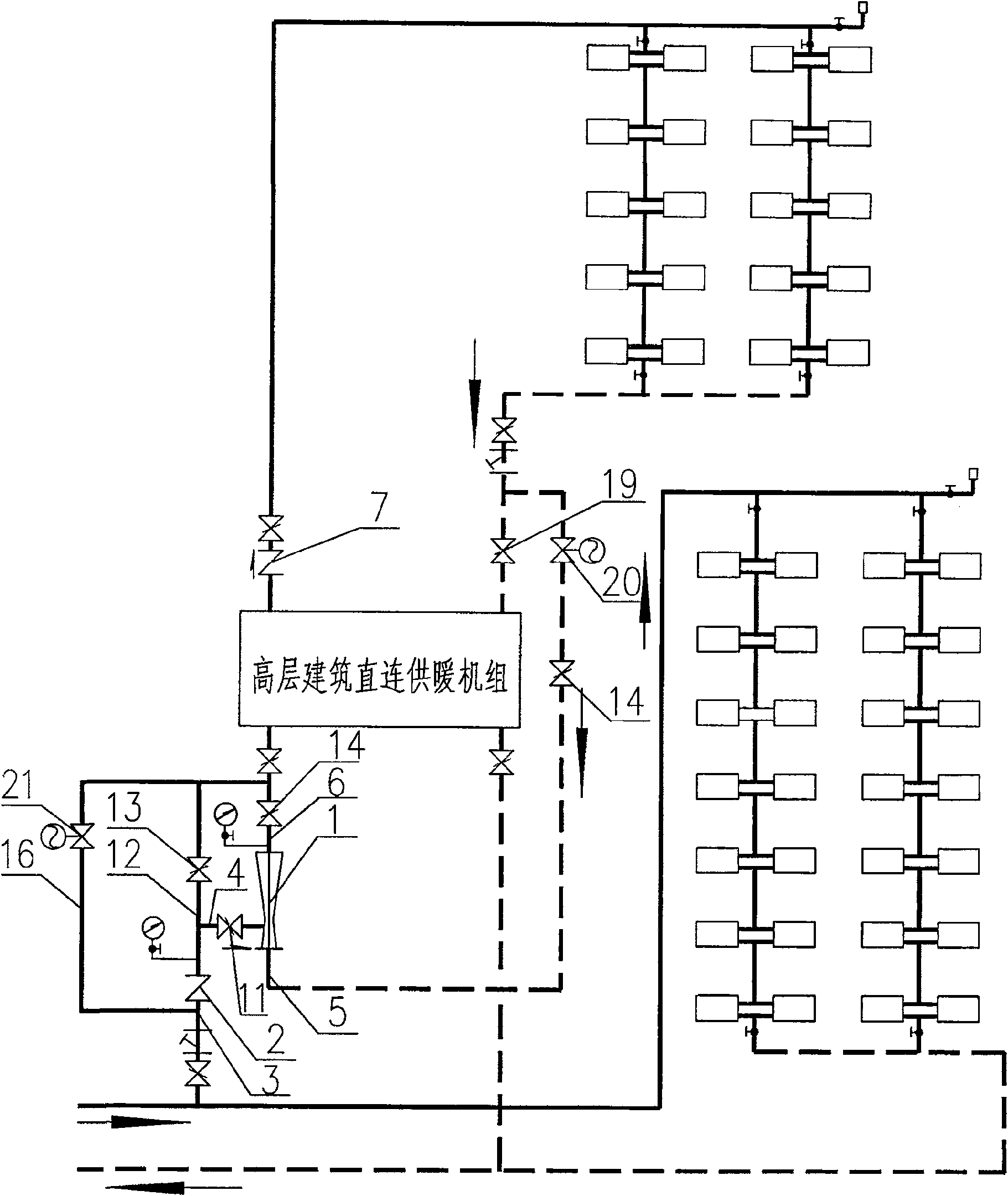

[0009] Now in conjunction with accompanying drawing, the present invention will be further described: figure 1 It is the first structure schematic diagram of the direct-connected heating self-pressurization unit for high-rise buildings of the present invention. The water injector 1 injects the water supply in the low area to start the check valve 2, and the water supply pipe section 3 of the check valve 2 is connected to the water supply pipe of the municipal heating pipe network, and the water outlet pipe 4 behind the check valve 2 can pass through the water injector 1 and High-rise buildings are directly connected to the suction pipes of the heating units. The water injector 1 is connected to the main return pipe of the heating system in the high area through the water inlet pipe section 5, and the outlet pipe section 6 of the water ejector 1 is connected to the water suction pipe directly connected to the heating unit of the high-rise building, and the pipe section 5 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com