Press machine with a servo-drive system and a continuous process system

A technology of servo drive and servo motor, which is applied in the direction of stamping machines, presses, mechanical equipment, etc., can solve the problem of high peak power of the control circuit, achieve the effect of no transmission delay, no control delay, and prevent deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] Embodiments of the present invention will be described below with reference to the drawings.

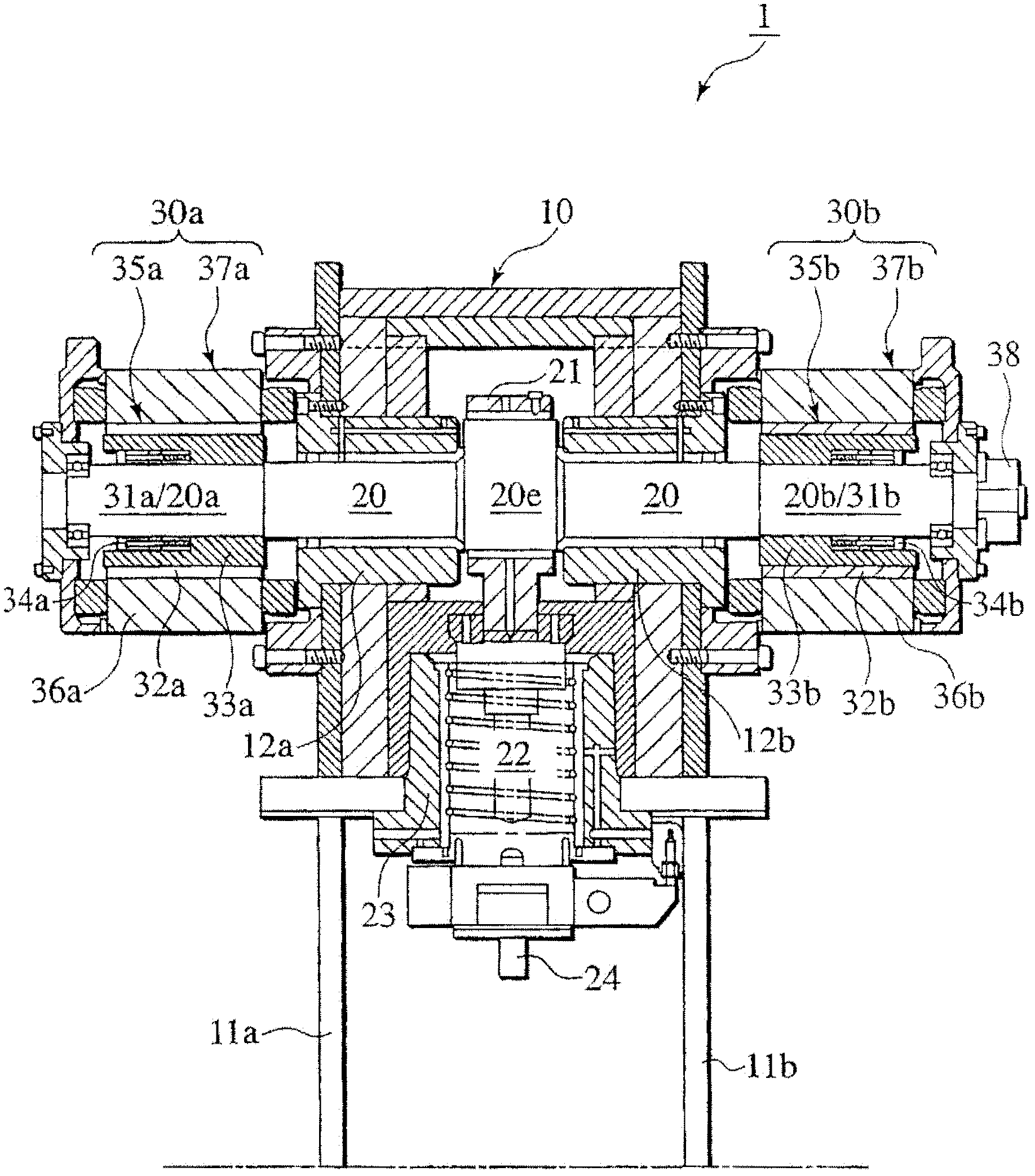

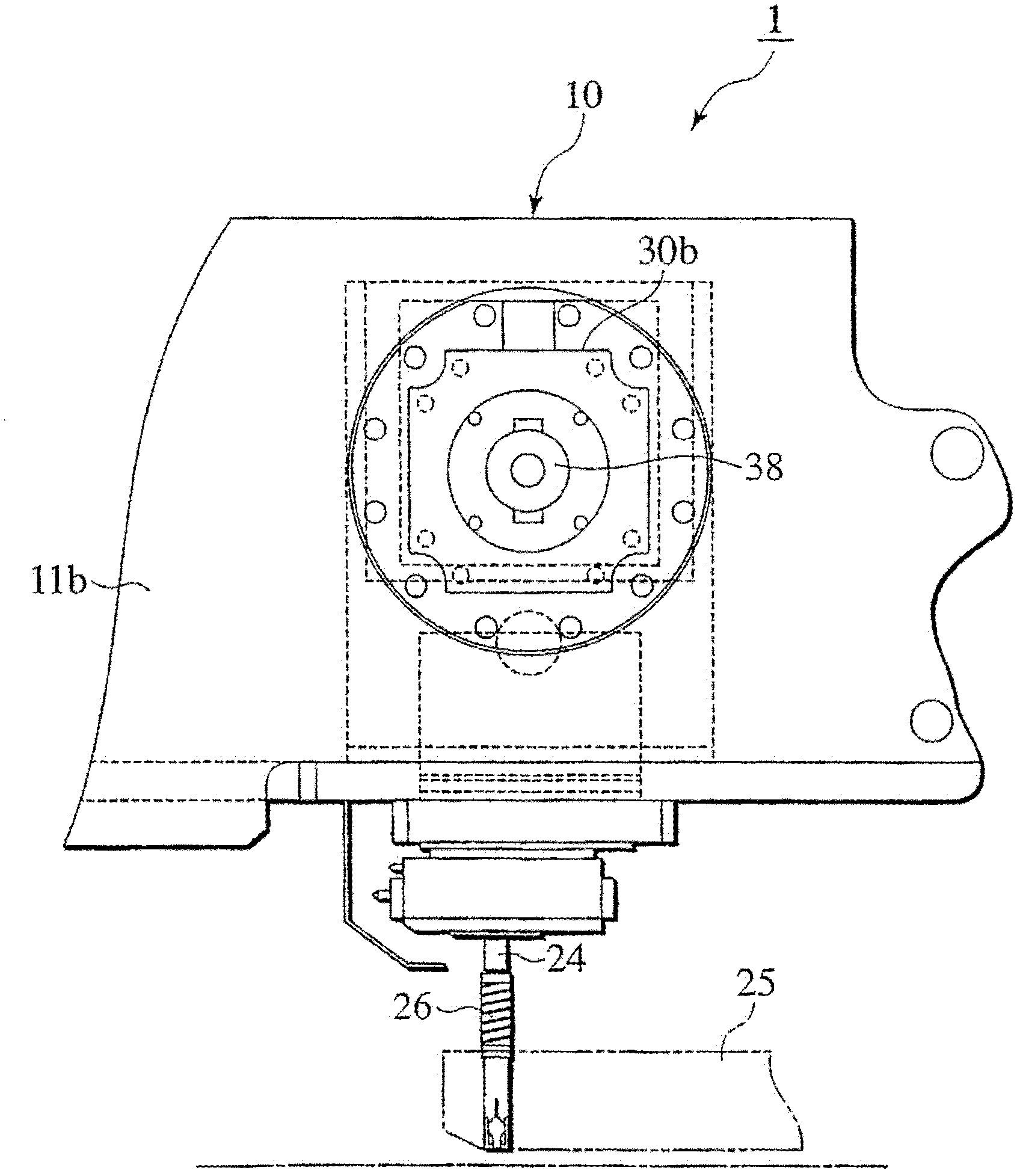

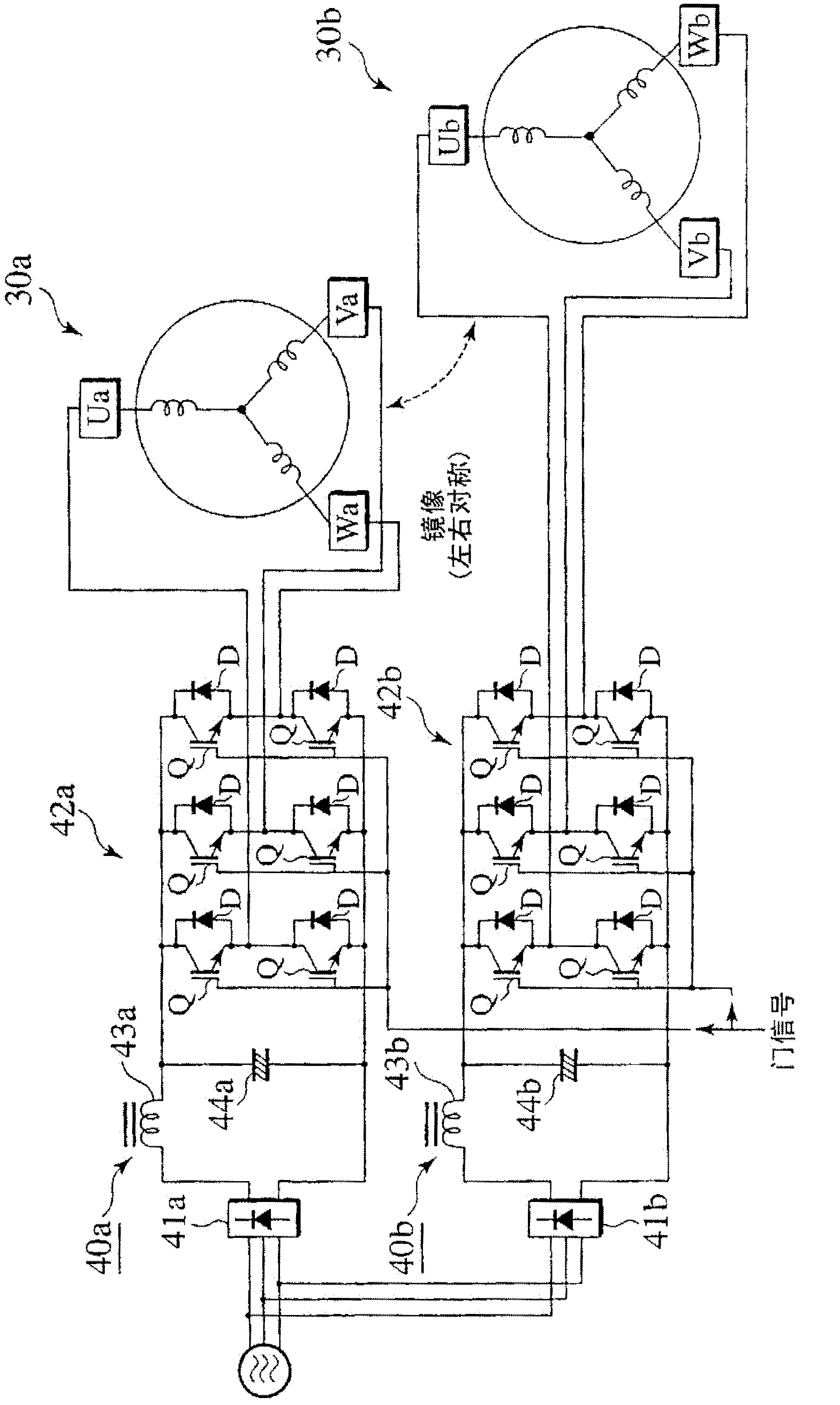

[0059] figure 1 It is a longitudinal sectional view showing an essential part of an embodiment of a servo drive system (continuous processing system) of a press machine according to the present invention, figure 2 It is the right side view, and the servo drive system (continuous processing system) 1 of this press machine is used in the turret press machine 10 .

[0060] In the turret press machine 10, an eccentric shaft 20 is pivotally supported on bearing portions 12a, 12b provided on brackets 11a, 11b erected in parallel. On the eccentric shaft portion 20e of the eccentric shaft 20 located approximately in the center between the brackets 11a, 11b, the punch 22 is installed through the connecting rod 21, and by the rotation or rotation of the eccentric shaft 20, the punch 22 is moved along the punch through the connecting rod 21. The conduit 23 moves up and down, and the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com