Coal body and anchoring agent interface bonding strength testing method

A technology of strength testing and interfacial bonding, which is used in the testing of bonding strength and the bonding strength of coal and anchoring agent interfaces. Difficult to process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

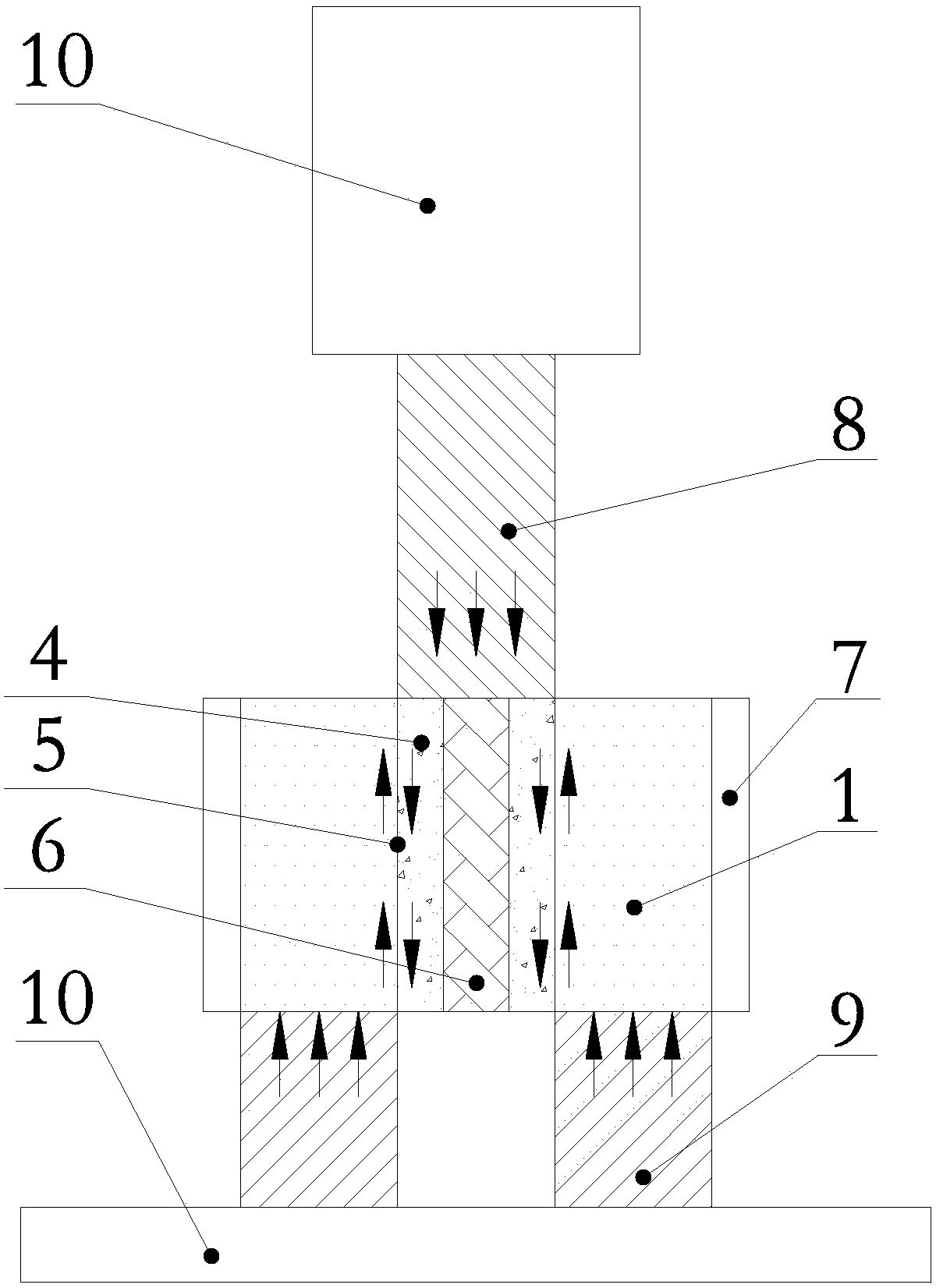

[0033] The invention will be described in further detail below in conjunction with the accompanying drawings.

[0034] A method for testing the interface bond strength between a coal body and an anchoring agent provided by the invention comprises the following steps:

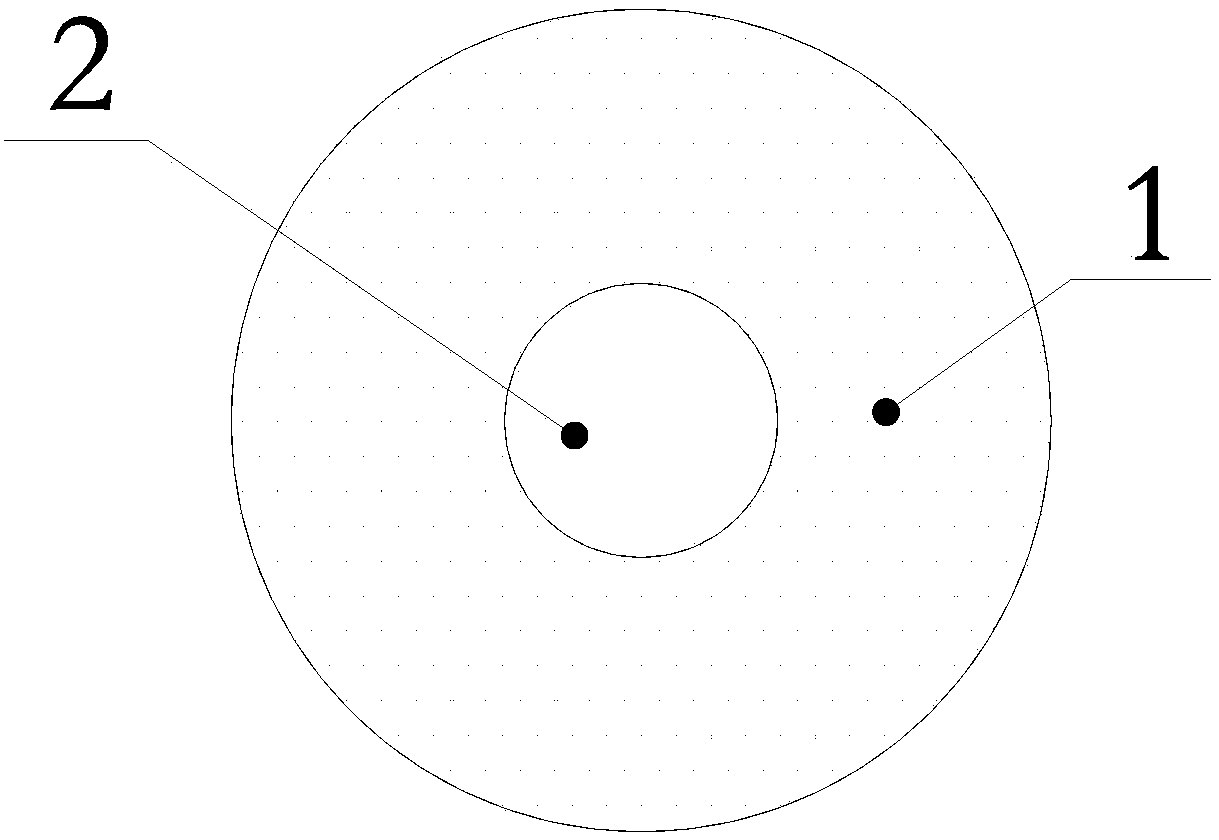

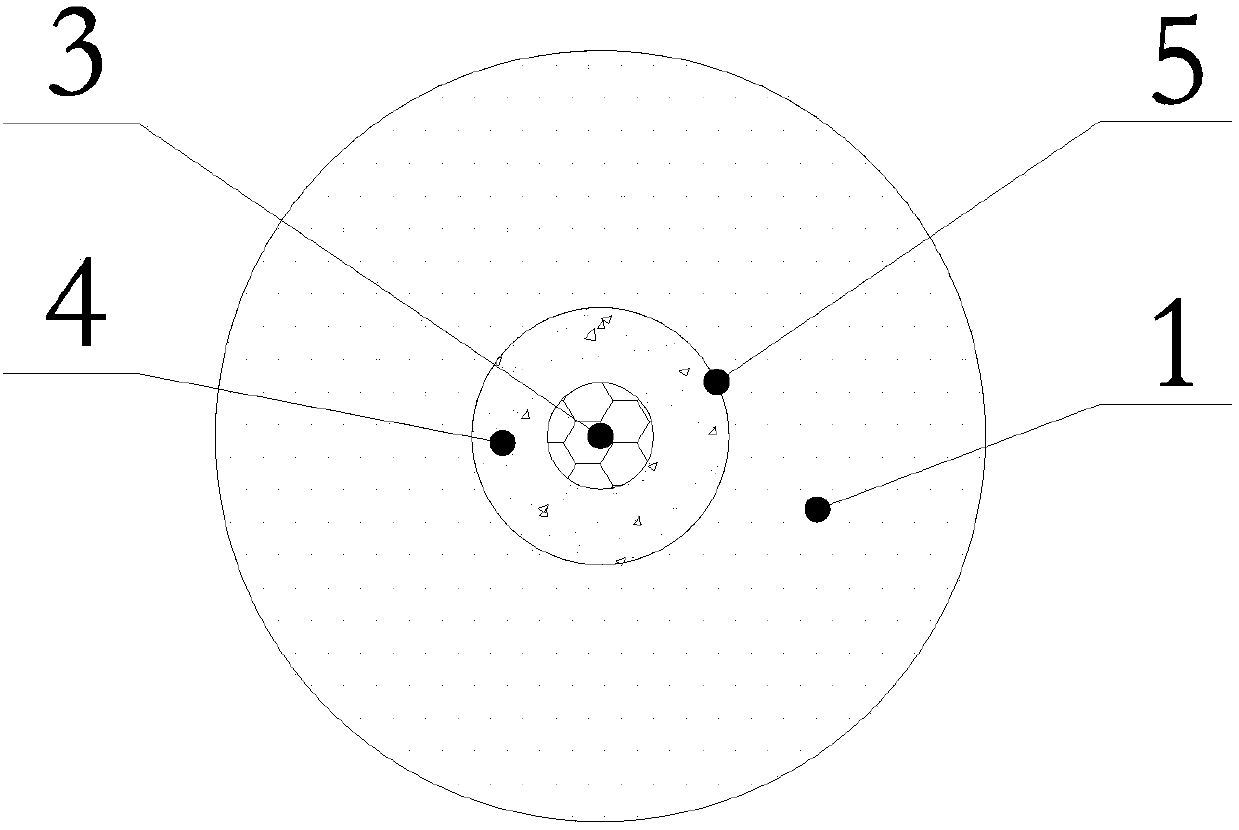

[0035] (1) Production of coal matrix 1: Take coal samples on site, and press the coal body into coal matrix 1 according to the occurrence status of the coal body on site, and form a circular through hole 2 with a diameter equal to that of the drilled hole in the middle of coal matrix 1 ,Such as figure 1 As shown, the coal matrix 1 is the size required for the experiment;

[0036] Due to poor coal strength, loose and broken, especially soft coal, it is difficult to process into complete and regular-shaped specimens, so it is processed by pressing; under different buried depth conditions, the physical properties of coal are quite different, so When pressing the coal matrix 1, factors such as burial depth should ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com