A method for testing the strength of coal body reinforced by jet grouting

A technology of strength testing and grouting reinforcement, which is applied in the direction of testing material strength by applying stable shear force, testing material strength and strength characteristics by applying stable tension/pressure, and can solve the problem of difficult-to-loose coal roadway control, lack of Quantitative evaluation, lack of coal strength characteristics, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0041] A method for testing the strength of a jet grouting reinforced coal body, comprising the following steps:

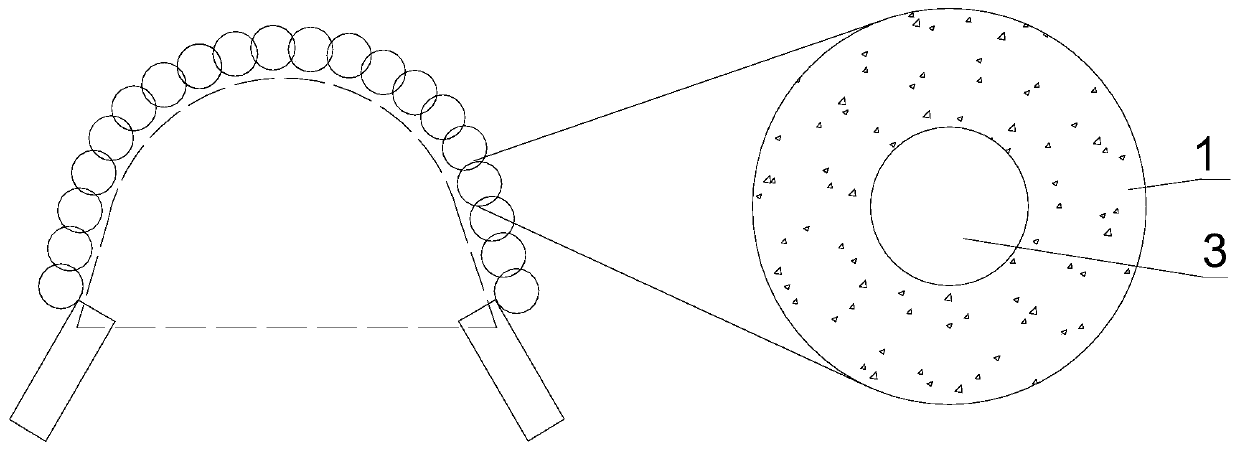

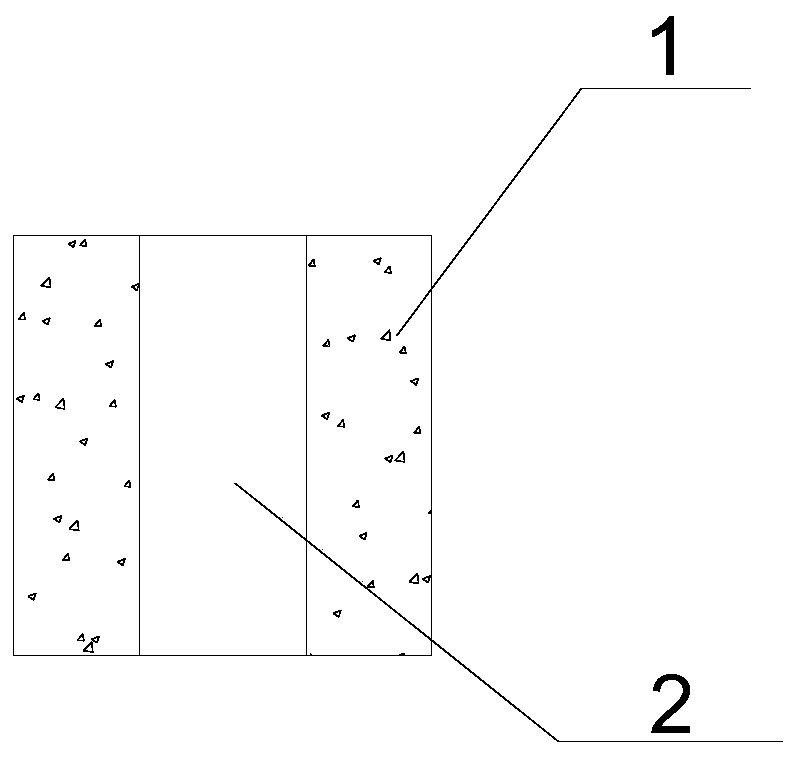

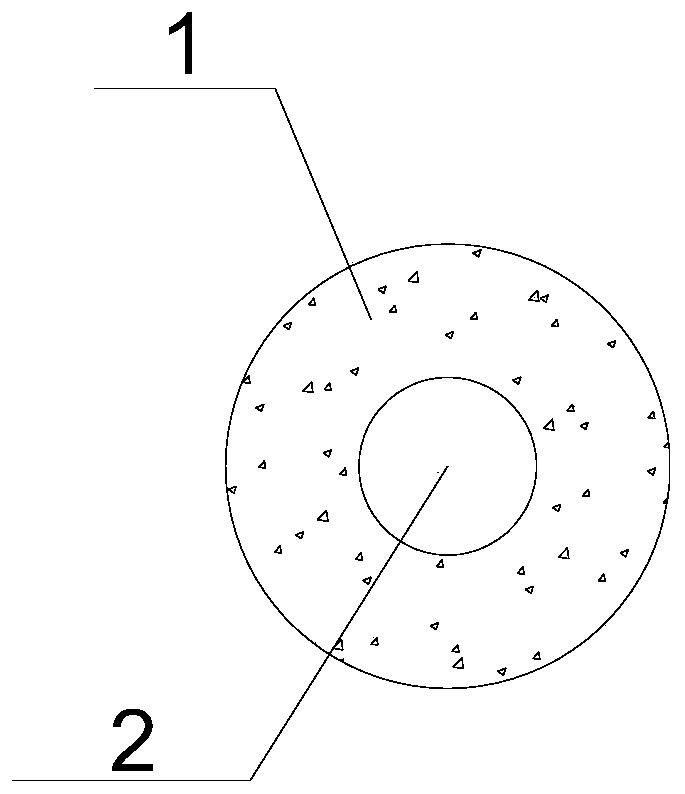

[0042] (1) Making the coal matrix 1: taking coal samples on site, and pressing the coal body into the coal matrix 1 according to the on-site coal occurrence state, and forming a circular through hole 2 in the middle of the coal matrix 1, such as figure 2 and image 3 As shown, the coal matrix 1 is the size required for the experiment;

[0043] Due to poor coal strength, loose and broken, especially soft coal, it is difficult to process into complete and regular-shaped specimens, so it is processed by pressing; under different buried depth conditions, the physical properties of coal are quite different, so When pressing the coal matrix 1, factors such as the depth of burial should be considered; for the convenience of pressing and subsequent te...

PUM

| Property | Measurement | Unit |

|---|---|---|

| friction angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com