Transmission system of servo-driven double-angle lever mechanical press of switch magnetic reluctant motor

A technology of mechanical presses and switched reluctance, applied in the directions of presses, punching machines, manufacturing tools, etc., can solve problems such as the inability to meet the requirements of economy, green manufacturing, and inability to drive mechanical presses, so as to improve market competitiveness and simplify the structure. , the effect of reducing the cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

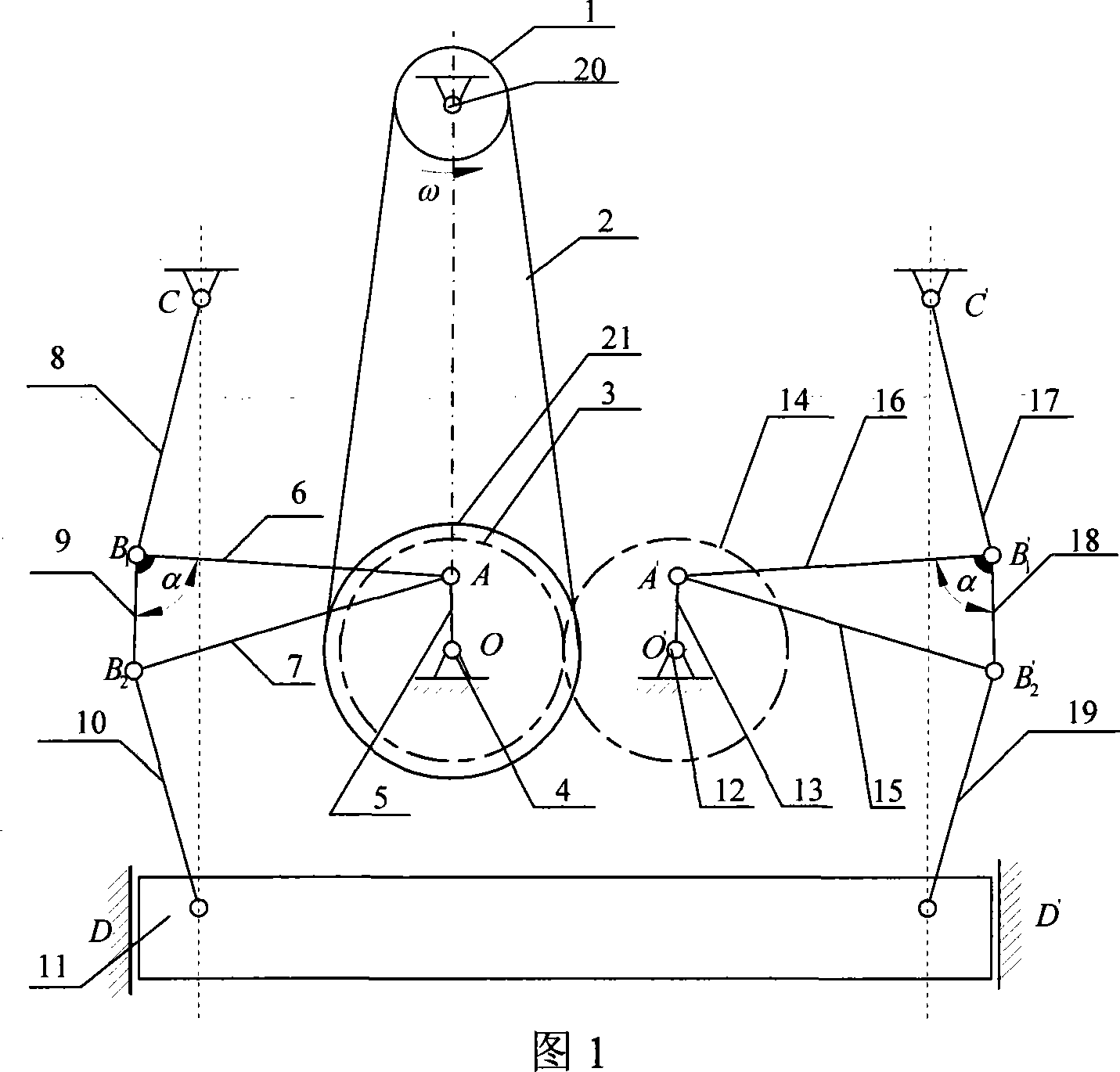

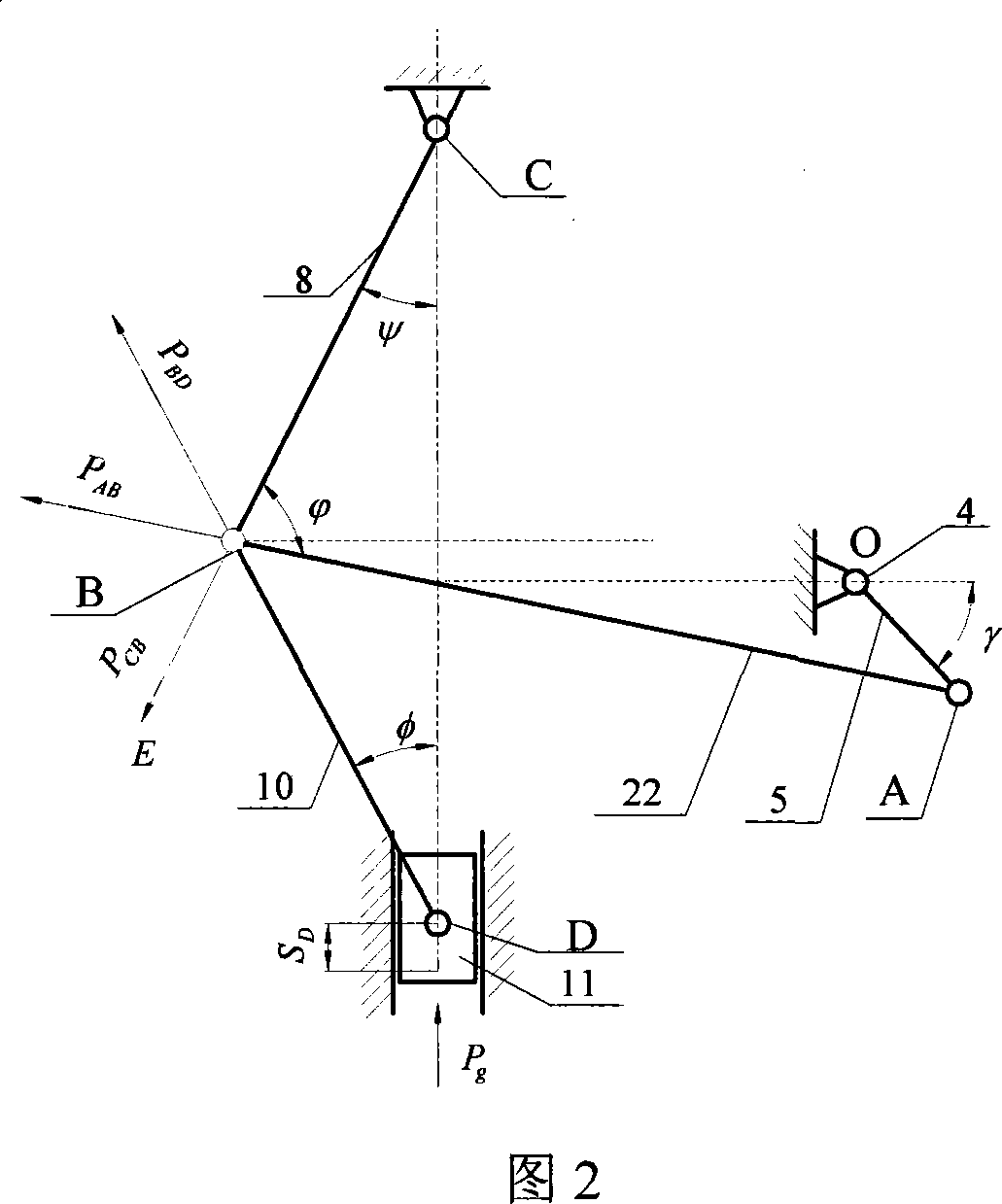

[0026] 1, the switched reluctance motor transmission shaft 20 is keyed to the small pulley 1, the small pulley 1 is connected to the large pulley 21 through the belt 2, and the large pulley 21 is keyed to the main transmission shaft 4; the main gear 3 is connected to the main transmission shaft 4 key link, pinion gear 14 and counter drive shaft 12 key link; the various parameters of main gear 3 and pinion gear 14 are completely equal, and the two mesh to make main drive shaft 4 and counter drive shaft 12 synchronously drive; one end of main crank 5 is connected to main drive The shaft 4 is fixedly connected, and the secondary crank 13 is fixedly connected with the secondary transmission shaft 12; the rigid body AB 1 B 2 Respectively at point A and the main crankshaft 5-pin link, at point B 1 Linked with the 8 pins of the main upper toggle, at point B 2 is linked with the main lower toggle 10 pin; the rigid body triangle A′B 1 'B 2 ′ length of three sides and the rigid body...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com