Mechanical multi-link servo press driven by six parallelly-connected motors

A technology of servo press and driving machinery, applied in the field of forging machinery, can solve the problems such as the failure of the driving mechanism to work normally, the deterioration of the control stability, and the increase of the forming pressure of the press, so as to improve the anti-eccentric load capacity and easy control. , the effect of reducing wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The following is a detailed description of the embodiments of the present invention. This embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following implementation example.

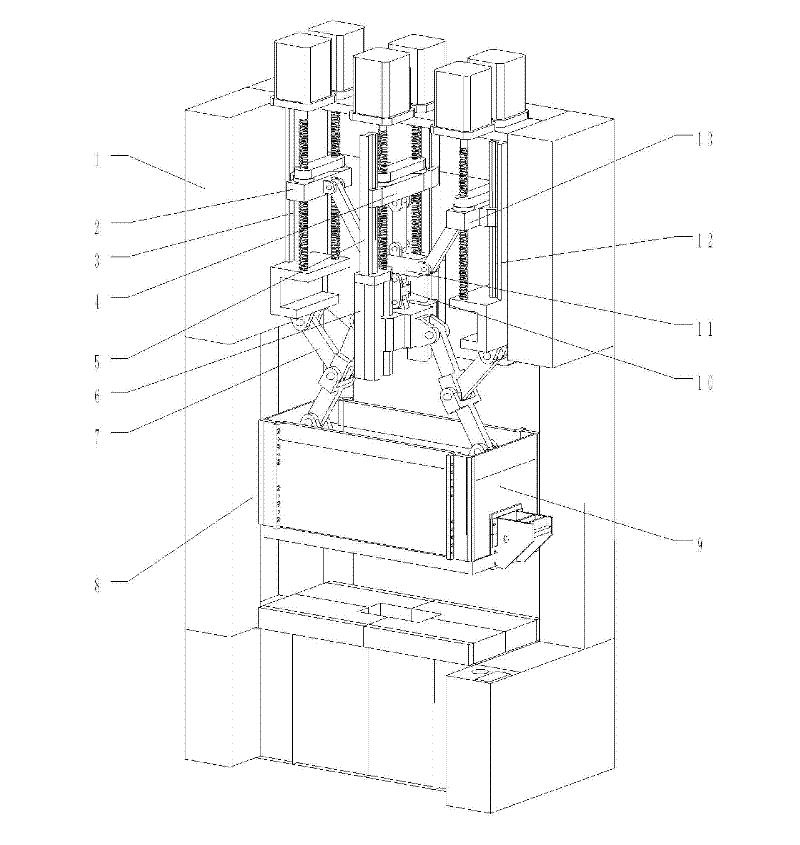

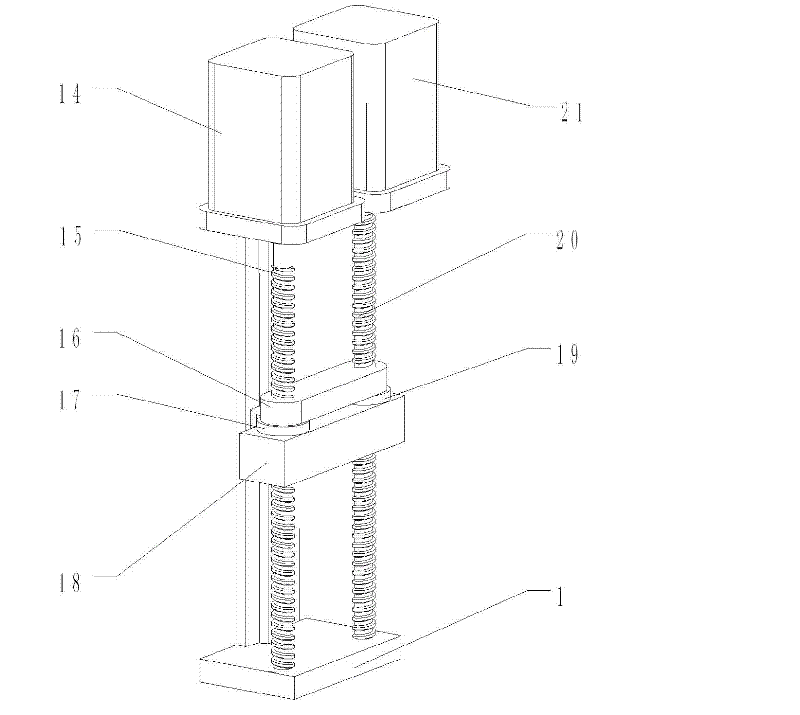

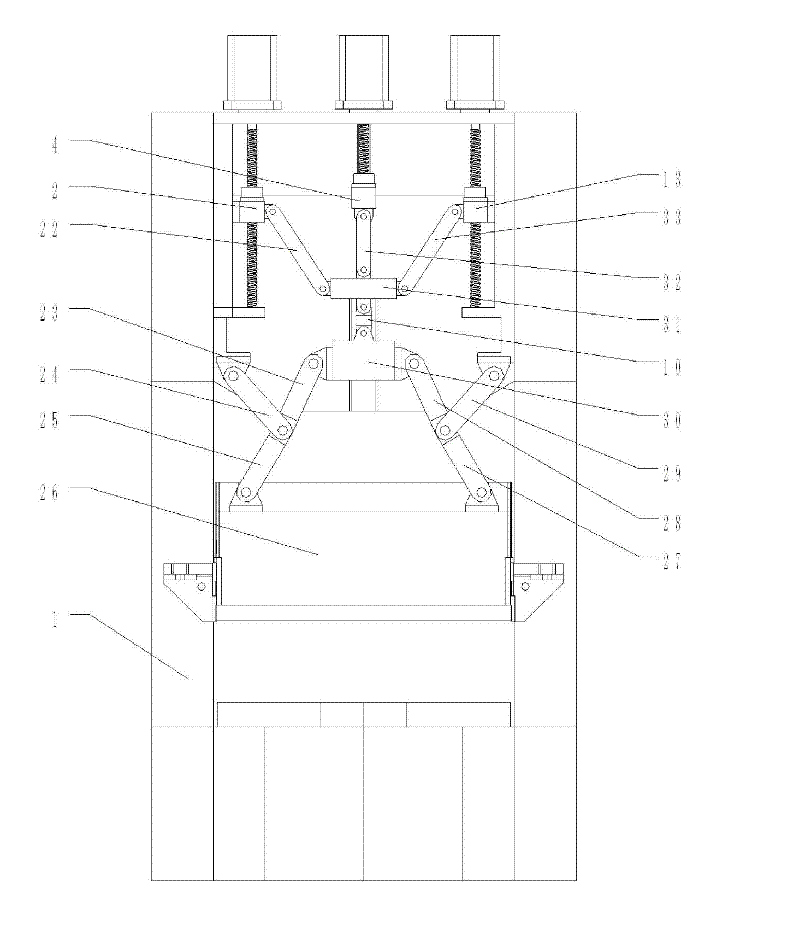

[0019] Such as figure 1 As shown, this embodiment includes: frame 1, first linear drive mechanism 2, first guide rail 3, second linear drive mechanism 4, second guide rail 5, fourth guide rail 6, toggle mechanism 7, fifth guide rail 8. Stamping slider 9, slider connecting rod 10, parallel mechanism 11, third guide rail 12 and third linear drive mechanism 13, wherein: first linear drive mechanism 2, second linear drive mechanism 4, third linear drive mechanism The output end of the mechanism 13 is used as the input end of the parallel mechanism 11 respectively, the slider connecting rod 10 is used to c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com