System and method for accurately measuring dynamic change of porosity of loaded coal rock

A technology of dynamic change and porosity, applied in the direction of measuring device, permeability/surface area analysis, suspension and porous material analysis, etc., can solve problems such as high maintenance and operating conditions, low measurement accuracy, and increased measurement error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

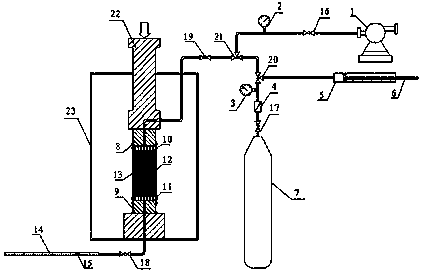

[0031] Such as figure 1 As shown, a system for accurately measuring the dynamic change of the porosity of loaded coal rocks includes a triaxial pressure chamber 23 and a triaxial servo press 22, the upper pressure head 8 of the triaxial servo press 22, the lower pressure The head 9 is located in the triaxial pressure chamber 23, which also includes a heat-shrinkable tube 13 between the upper pressure head 8 and the lower pressure head 9 for loading the coal rock sample 12; the bottom end of the upper pressure head 8, The top of the lower pressure head 9 is respectively blocked on the top and bottom of the heat shrinkable tube 13, the bottom surface of the upper pressure head 8 is provided with a first porous plate 10, and the top surface of the lower pressure head 9 is provided with a second porous plate 11 , the upper pressure head 8 is provided with an upper air channel, and the lower pressure head 9 is provided with a lower air channel, the upper air channel communicates w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com