Servo pressing machine

A technology of servo presses and servo motors, applied in presses, punching machines, manufacturing tools, etc., can solve problems such as difficult to obtain treatment policies, and achieve the effect of shortening inspection time, preventing motor out of control, and reducing the frequency of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings.

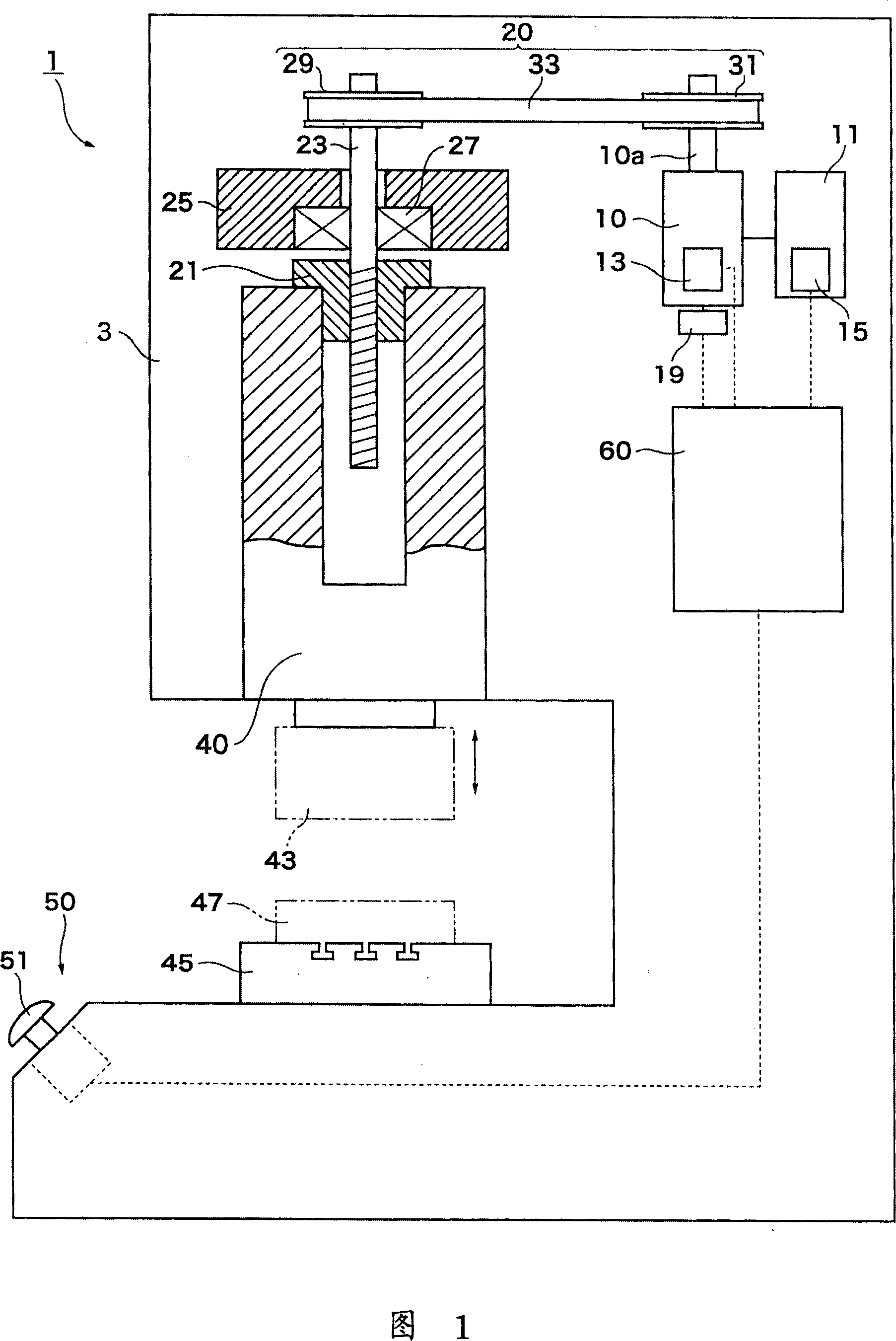

[0057] Fig. 1 is a diagram schematically showing the overall configuration of a servo press related to the first embodiment of the present invention.

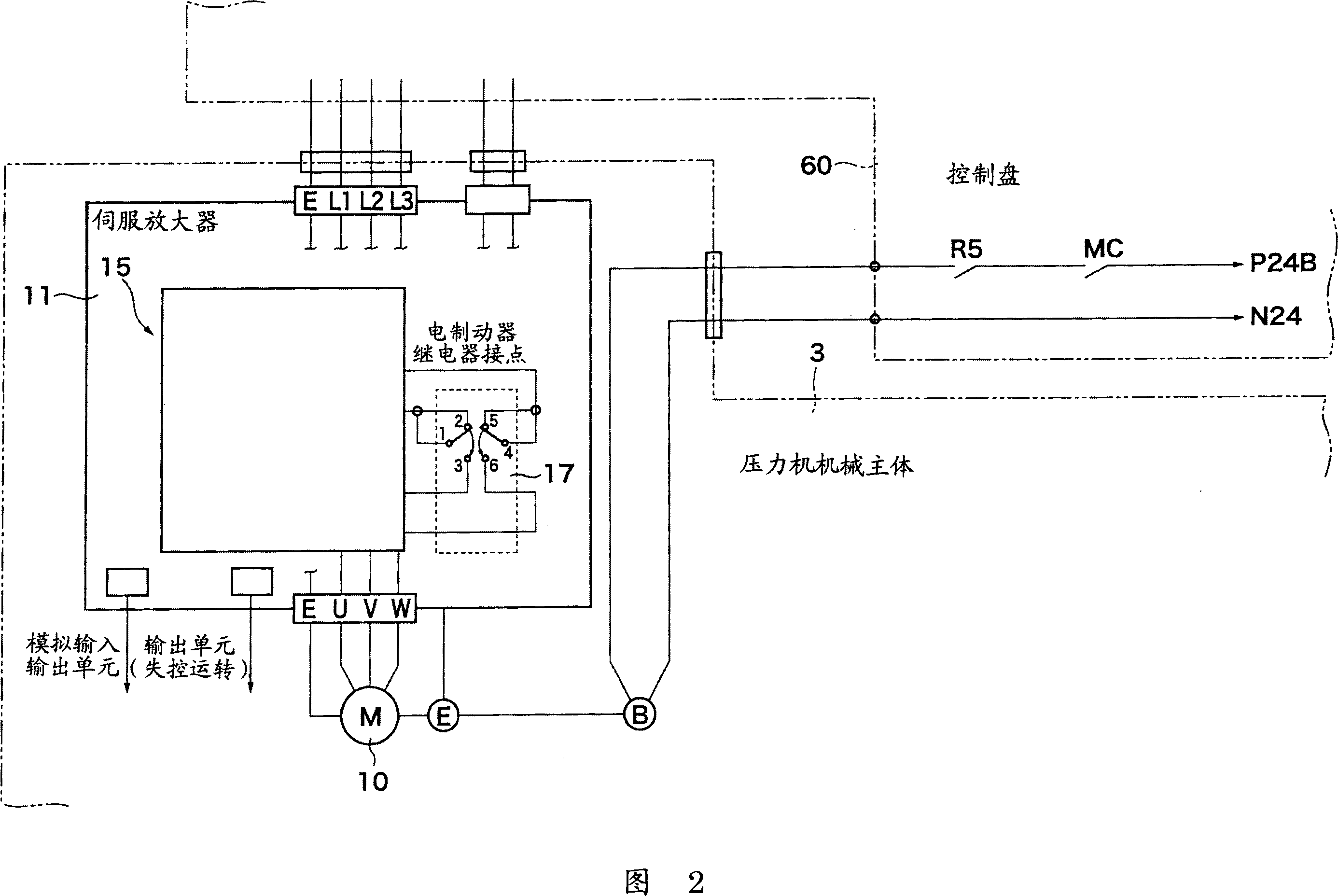

[0058] Fig. 2 is an example of the main part of the control circuit of the servo press of Fig. 1.

[0059] As shown in FIG. 1, the upper part of the main body box 3 of the servo press 1 is provided with a servo motor 10 and a motion conversion mechanism 20 that transmits the rotational motion of the motor 10 and converts it into linear motion. As the servo motor 10, for example, an AC servo motor can be used. The drive current of the servo motor 10 is controlled by a servo amplifier 11 electrically connected to the motor 10.

[0060] The motion conversion mechanism 20 has a ball screw 23 screwed with a nut 21 (of course, the conversion from rotational motion to linear motion may be performed by a crank mechanism or...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com