Triangular connecting rod-toggle rod transmission mechanism with large force magnification ratio for servo press

A technology of servo presses and triangular connecting rods, applied in the directions of presses, punching machines, manufacturing tools, etc., can solve the problems of non-optimal force increase ratio, insufficient force increase ratio, small pressure stroke, etc., so as to reduce the driving torque. , The effect of sufficient slider stroke and low speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

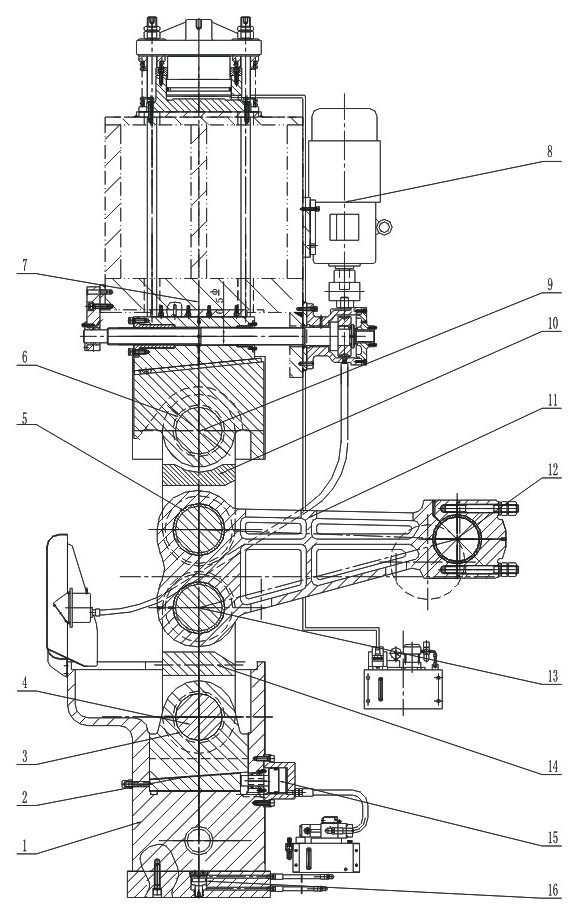

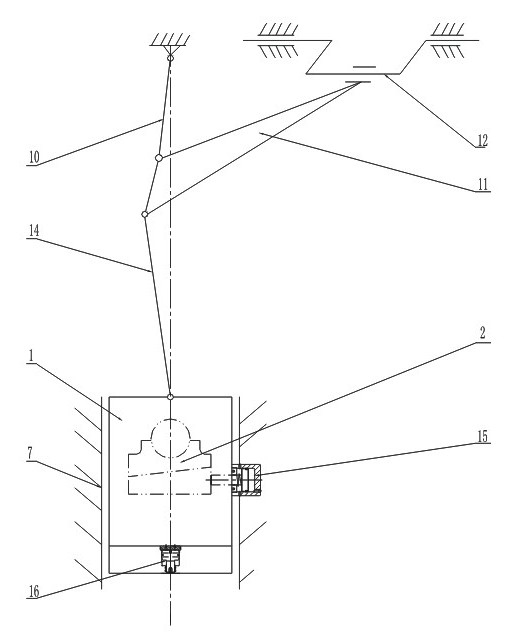

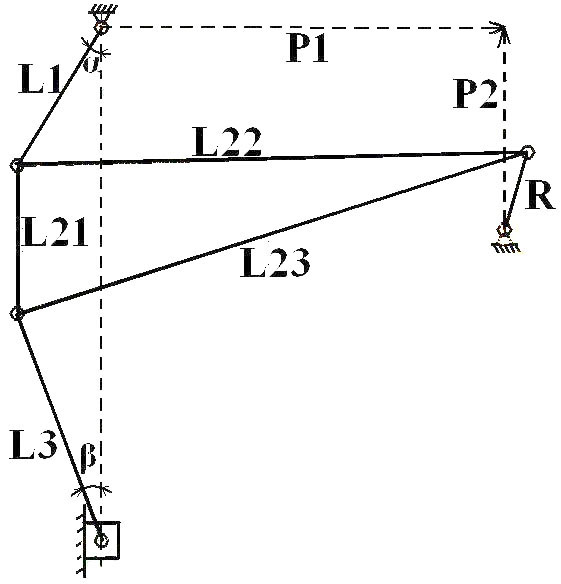

[0027] The front view of the triangular link-toggle link transmission mechanism of the present invention is as figure 1 As shown, include servo motor 8, upper pin 9, upper toggle 10, triangular connecting rod 11, crank 12, middle pin 13, lower toggle 14, unloading oil cylinder 15, top piece oil cylinder 16, wherein servo motor 8 The output shaft is connected with the crank 12 through the transmission mechanism, which drives the crank 12 to move, the crank 12 is connected with the connecting rod 11, drives the connecting rod 11 to swing, and the connecting rod 11 is respectively connected with the upper toggle 10 and the lower toggle 14, and the upper toggle 10 is hinged and fixed on the fuselage 7, and the lower toggle 14 is connected to the slider 1 that can move up and down linearly along the guide rail set on the fuselage 7 according to the kinematic characteristics set by the servo control system through the wedge-shaped overload protection block 2 and the unloading oil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com