Apparatus for controlling servopress and method for controlling the same

A technology of servo presses and control devices, which is applied to presses, stamping machines, manufacturing tools, etc., and can solve problems such as the difficulty in realizing high-speed slider drive and the inability to achieve high-production processing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

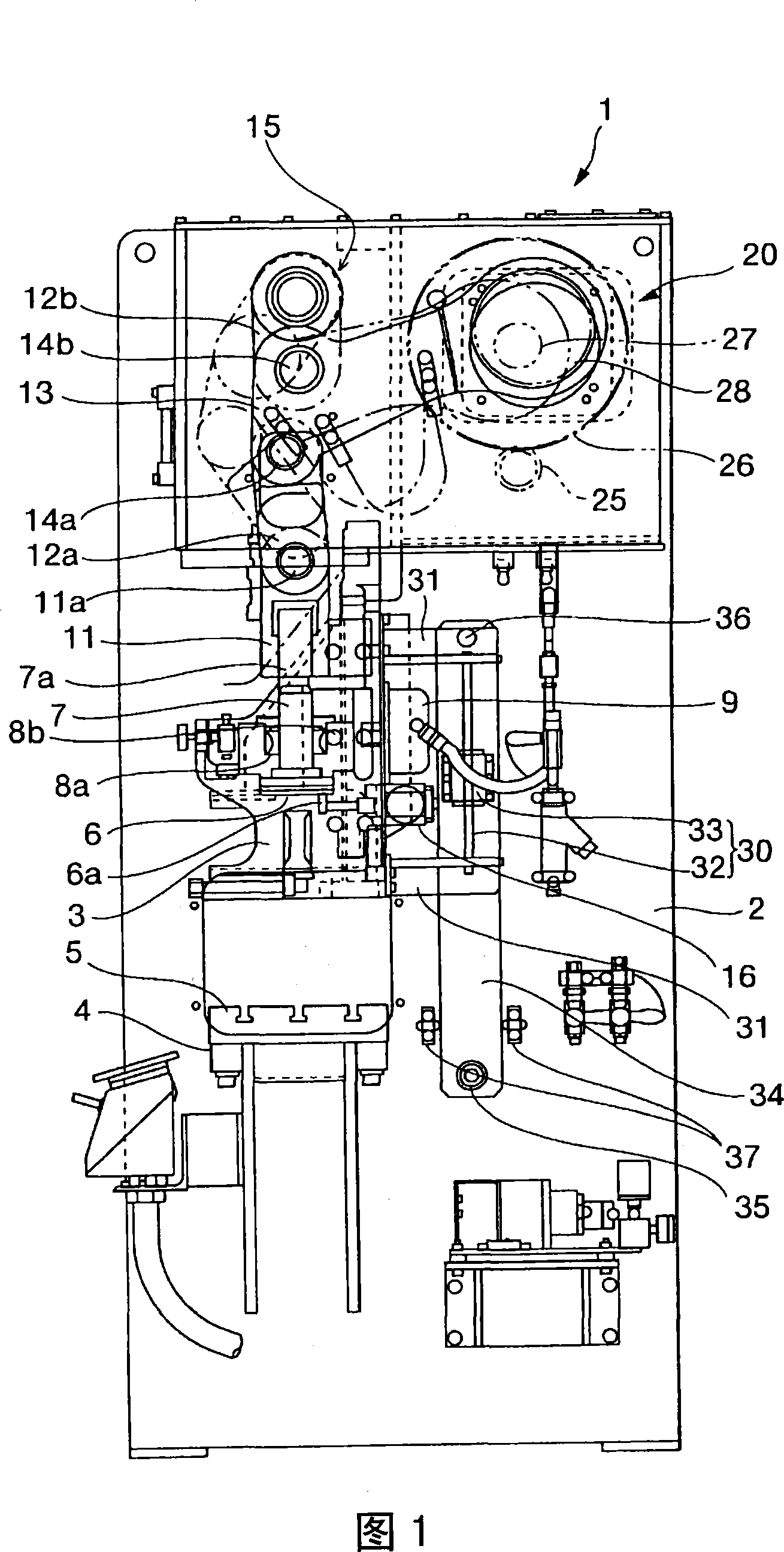

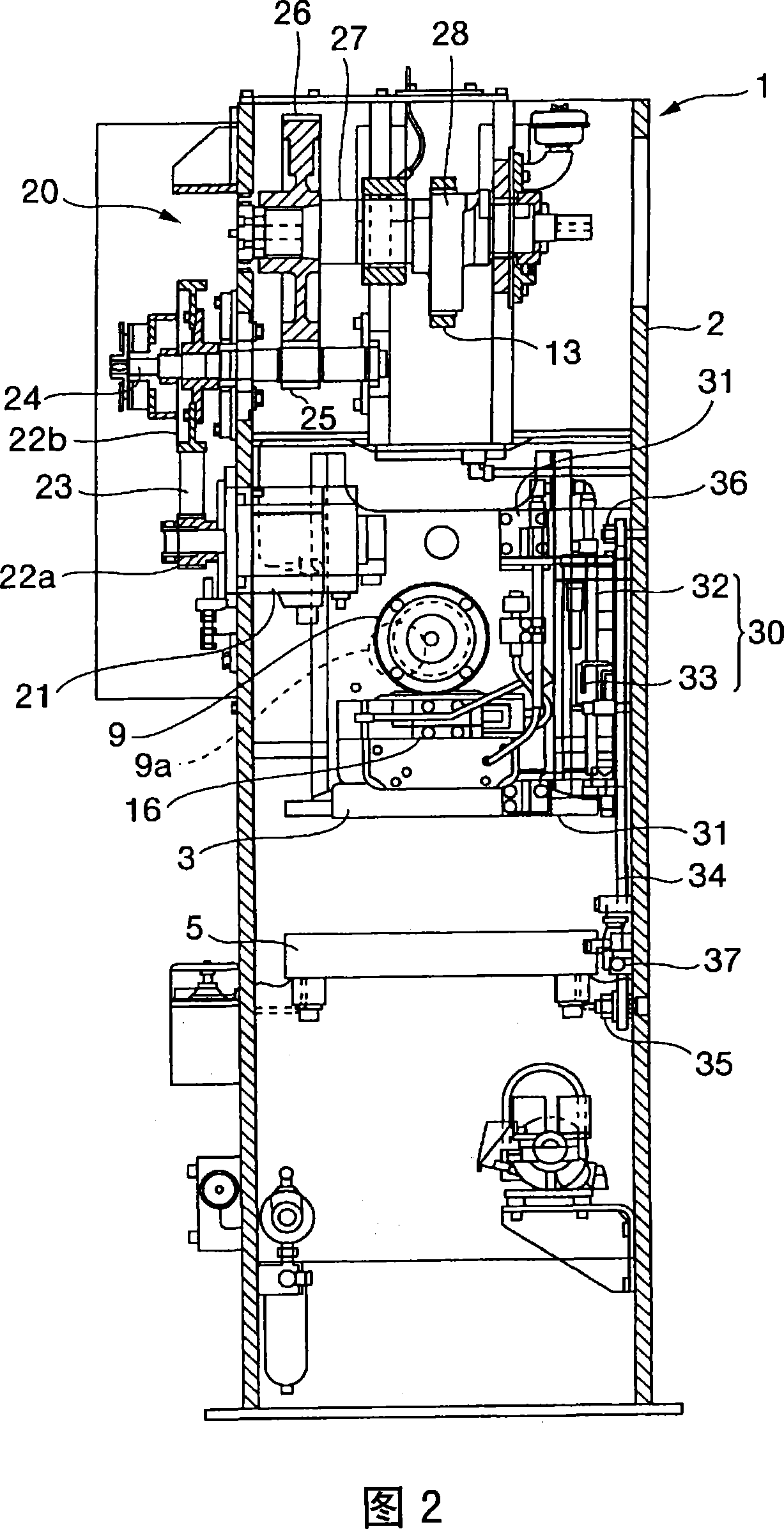

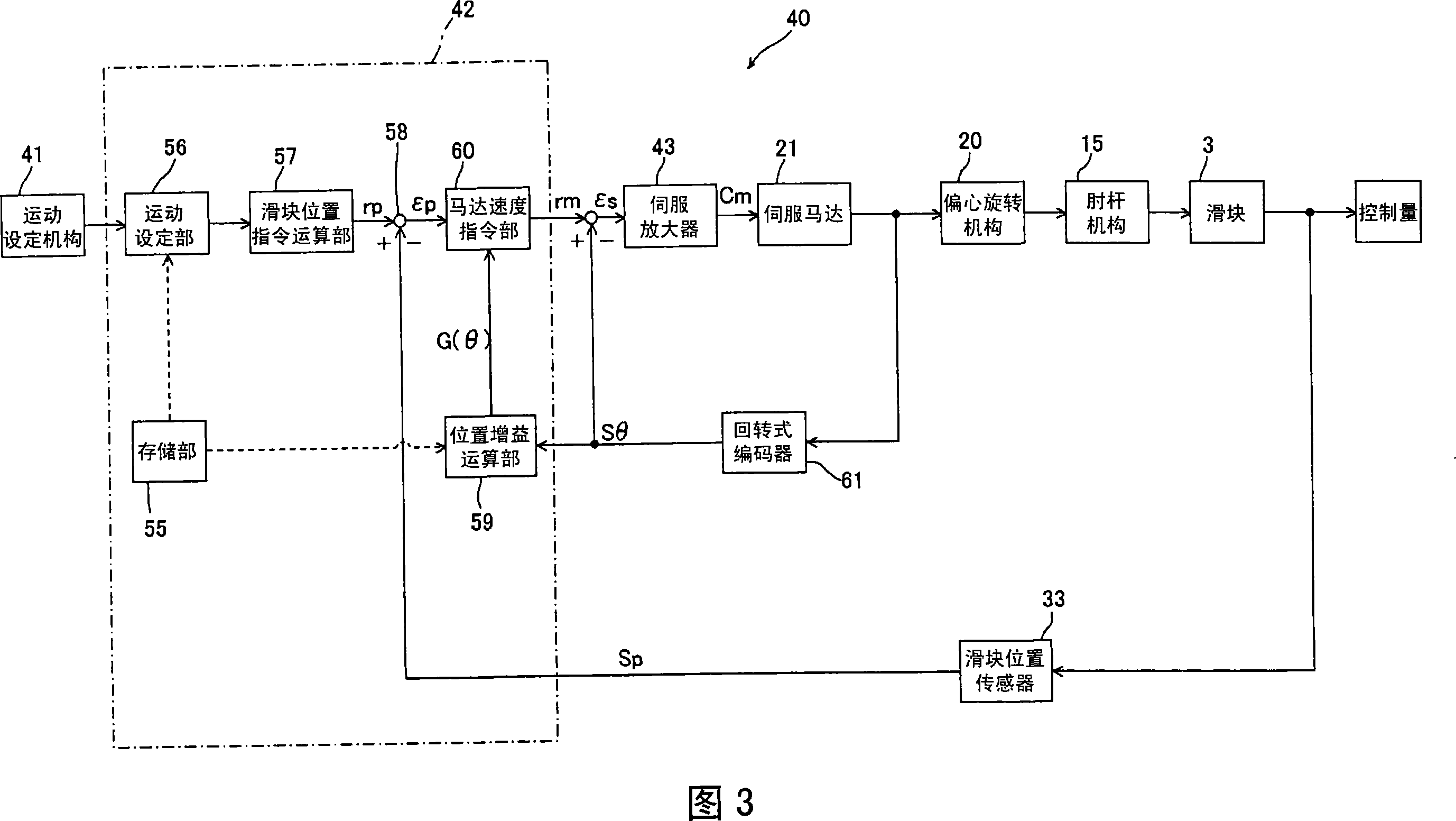

[0030] FIG. 1 shows a side partial sectional view of a servo press according to a first embodiment of the present invention, and FIG. 2 shows a rear partial sectional view of the same servo press.

[0031] In the servo press 1 according to the present embodiment, a slider 3 is vertically movably supported substantially at the center of the main body frame 2 . In addition, a base 4 is provided at the lower part of the main body frame 2, and a bolster 5 is attached to the base 4 to face the above-mentioned slider 3. As shown in FIG. Here, in the hole formed in the upper part of the slider 3, the body part of the threaded shaft 7 for adjusting the height of the die is rotatably inserted in a detached state. In addition, the threaded portion 7 a of the threaded shaft 7 is exposed upward from the slider 3 , and is screwed with an internal threaded portion formed at the lower portion of the plunger 11 provided above the threaded shaft 7 .

[0032] A worm wheel 8a is attached to the...

no. 2 Embodiment approach

[0067] Fig. 8 shows a schematic system configuration diagram of a servo press according to a second embodiment of the present invention. In addition, FIG. 9 shows an operation explanatory diagram (a) of a "rotation" figure and an operation explanatory diagram (b) of a "reverse" figure in the second embodiment, respectively. Also, the circle shown on the left side of each of Fig. 9 (a) and the same figure (b) represents the rotational movement of the gear 72 described later, and the rotation angle of the gear 72 corresponding to the top dead center is 0 degrees. The rotation angle of the gear 72 at the bottom dead center is 180 degrees. In addition, the time diagrams shown on the right side of each figure in Fig. 9 (a) and the same figure (b) show the change of the position of the slider along with the rotational movement of the gear 72, respectively, the horizontal axis represents the time, and the vertical axis represents the position of the slider. (high). In addition, in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com