Bottle-making machine and production process for manufacturing extra-large glass bottles

A production process and glass bottle technology, which is applied in glass production, glass blowing molding machines, special transmission machinery for glass blowing machines, etc. The effect of maintaining strength, less mold wear, and uniform bottle wall thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

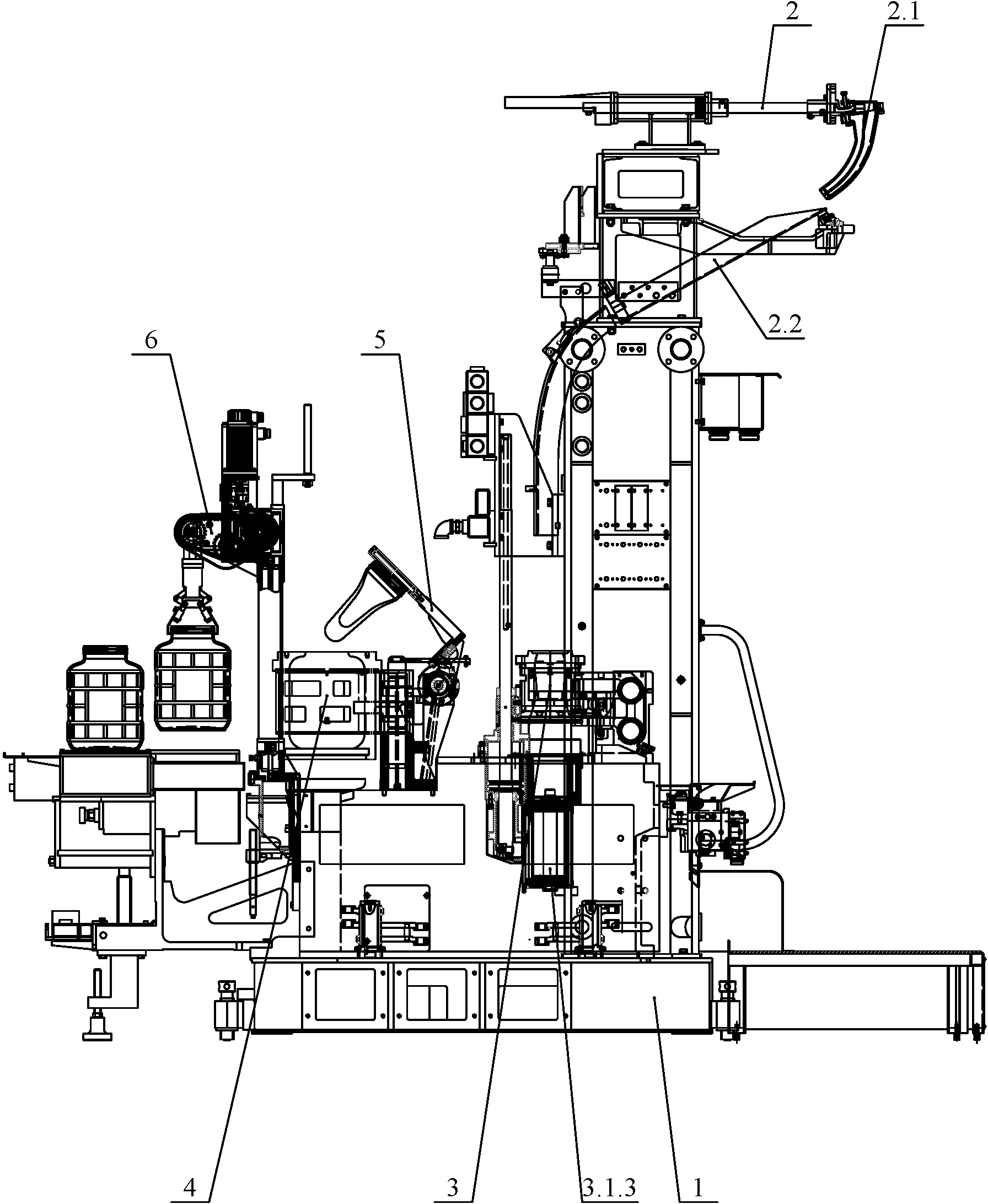

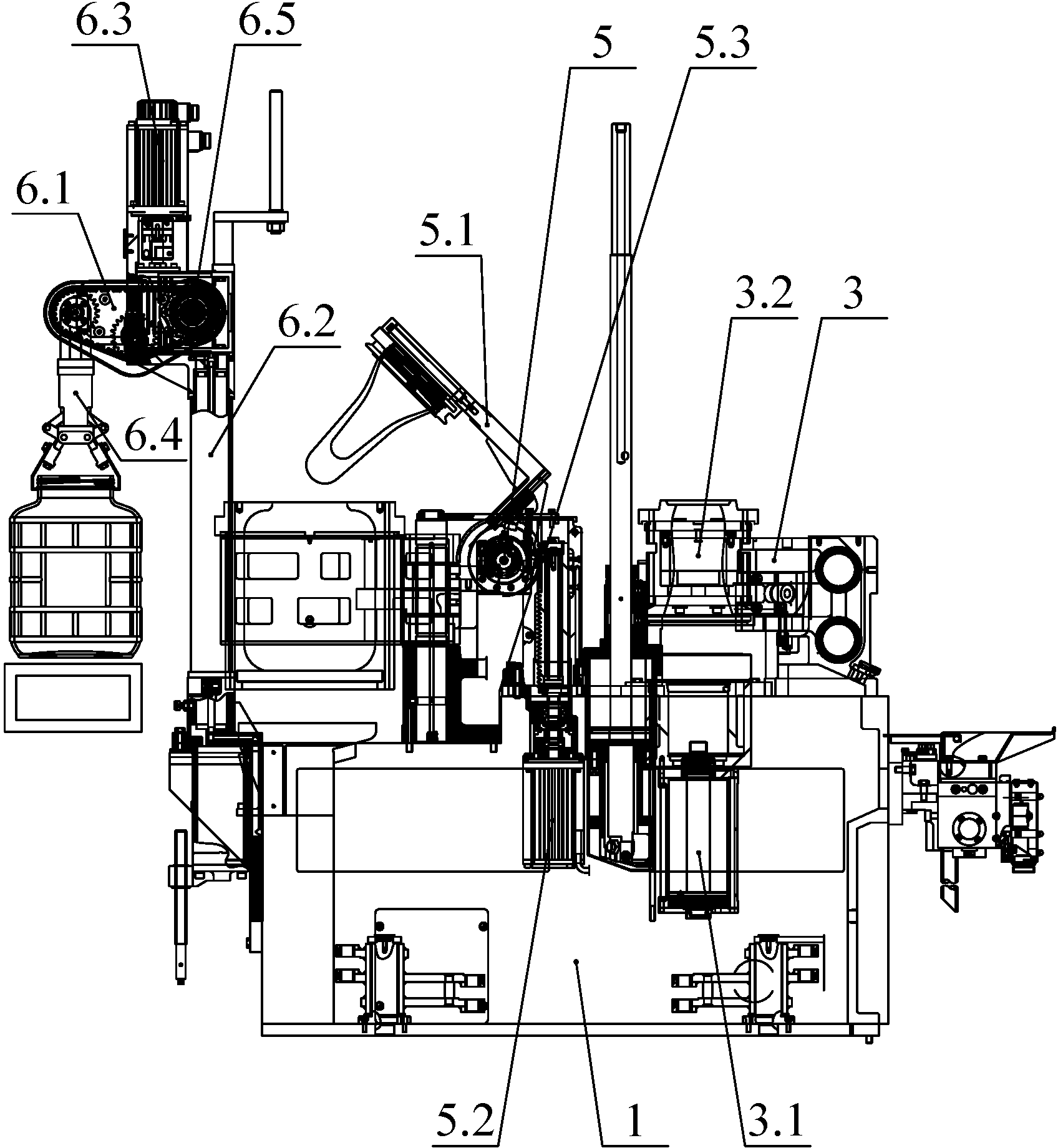

[0052] A bottle making machine for making extra large glass bottles such as figure 1 As shown, it includes a frame 1 and a preliminary mold forming mechanism 3 , a forming mold forming mechanism 4 and a turning device 5 all installed on the frame 1 .

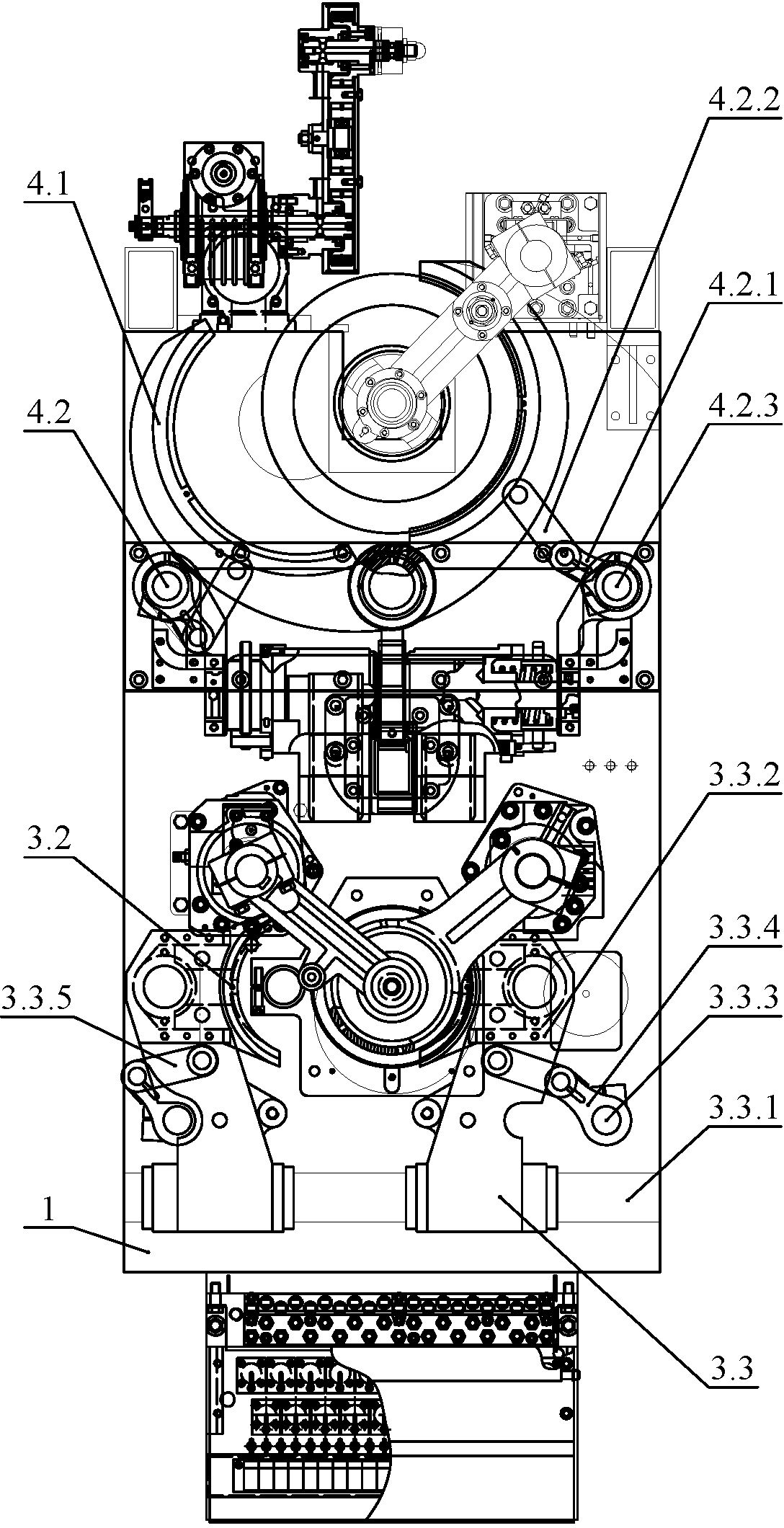

[0053] Such as Figure 4 As shown, the blank mold forming mechanism 3 includes a stamping device 3.1, a blank mold 3.2 and a parallel switch mechanism 3.3. The stamping device 3.1 is installed on the frame 1, and the parallel switch mechanism 3.3 includes a horizontal guide shaft 3.3.1 installed on the frame 1, a parallel clamp arm 3.3.2 set on the horizontal guide shaft 3.3.1, and a vertical set on the The first spline shaft 3.3.3, the first rocker arm 3.3.4, the first connecting rod 3.3.5 and the first switch cylinder on both sides of the frame 1. One end of the first connecting rod 3.3.5 is hinged with the parallel tong arm 3.3.2, and the other end is hinged with the first rocker arm 3.3.4. The first rocking arm 3.3.4 is c...

Embodiment 2

[0076] The difference from Example 1 is that the preliminary molding stage in this example uses the "blowing-blowing" method to obtain preforms. Such as Figure 9 As shown, the preliminary mold forming mechanism includes an air blowing device 3.5, and the blowing device is positioned under the preliminary mold. The blowing device includes a core 3.5.1, a buckle 3.5.2, a core joint 3.5.3, a core spring 3.5.5 and a blowing cylinder 3.5.6. The sleeve 3.5.4 is fitted around the core, and the core and the sleeve can slide relative to each other in the radial direction. The core and the core joint are connected by a buckle, and the lower end of the core joint is connected with the blowing cylinder. The core joint is connected with the cylinder block of the blowing cylinder by a core spring. A blowing channel is provided inside the core and the core joint, the top of the blowing channel passes through the side wall of the core and communicates with the outside world, and the botto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com