Sheet-type anode gasket welding wheel mechanism of solid aluminium capacitor

A technology of solid aluminum and capacitors, applied in capacitors, capacitor manufacturing, circuits, etc., can solve problems such as uncontrollable dimensional accuracy, no way to mass produce, difficult operation, etc., to achieve efficient and accurate superposition of welding dimensions, improve welding quality, and ensure consistency sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

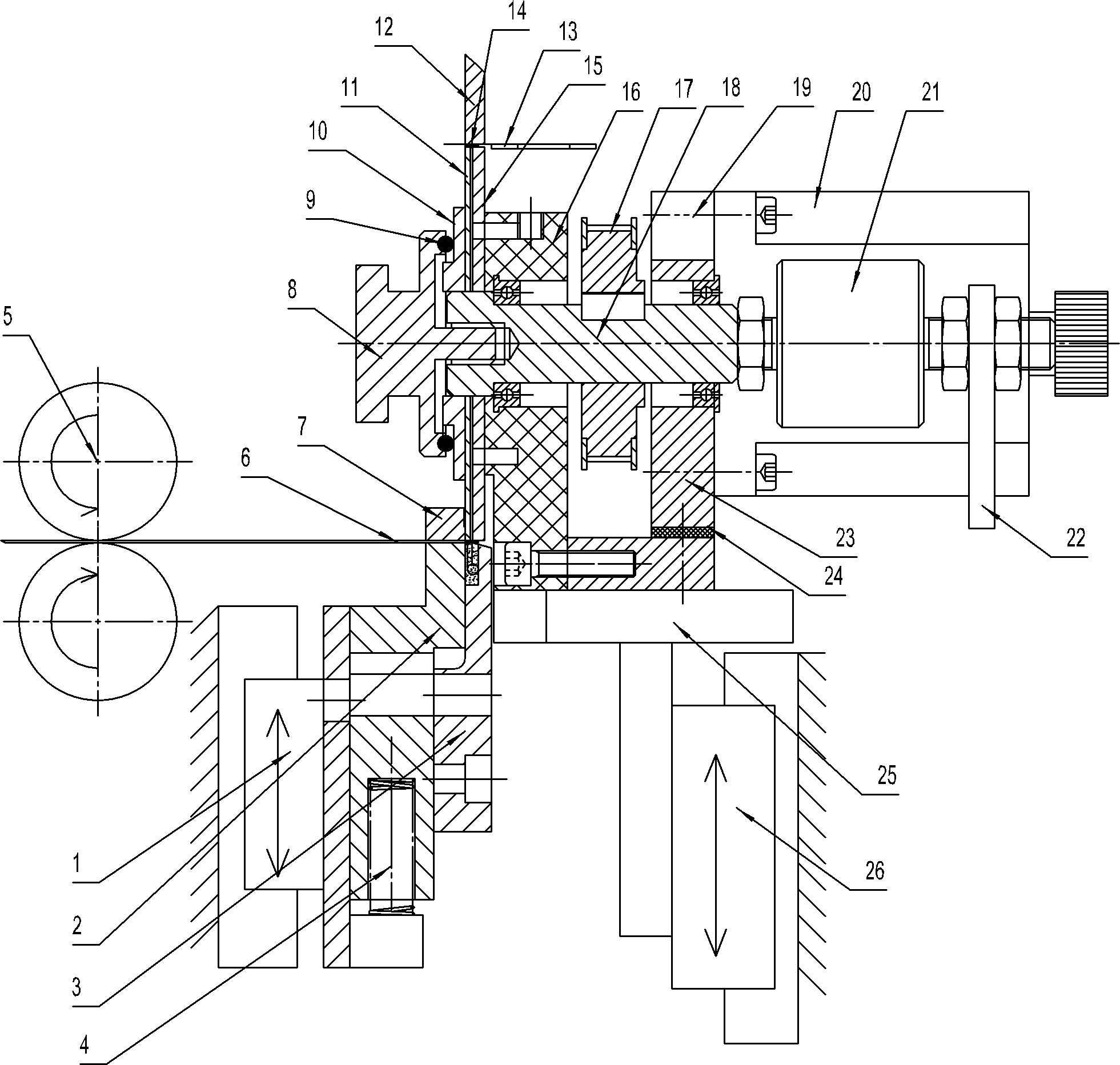

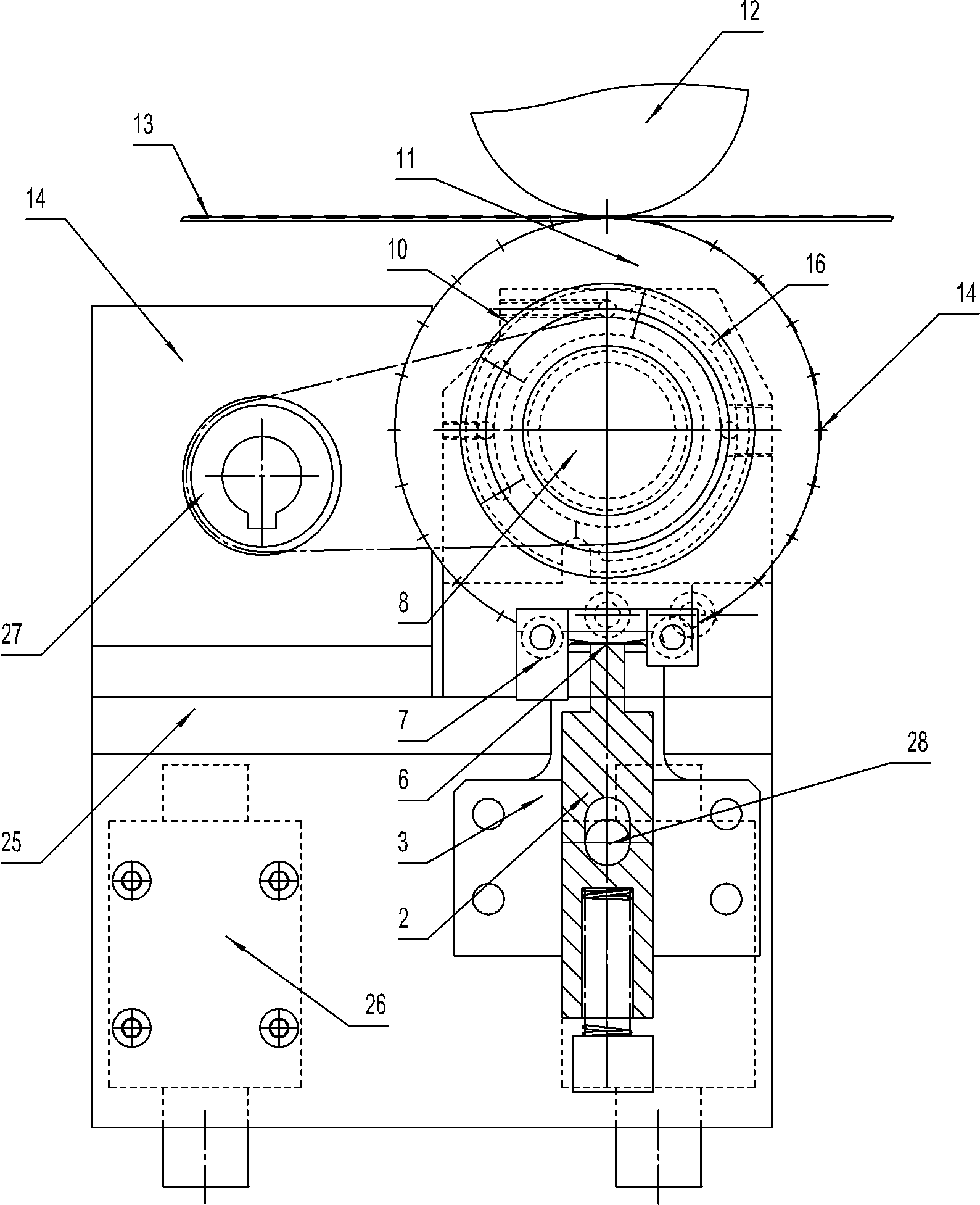

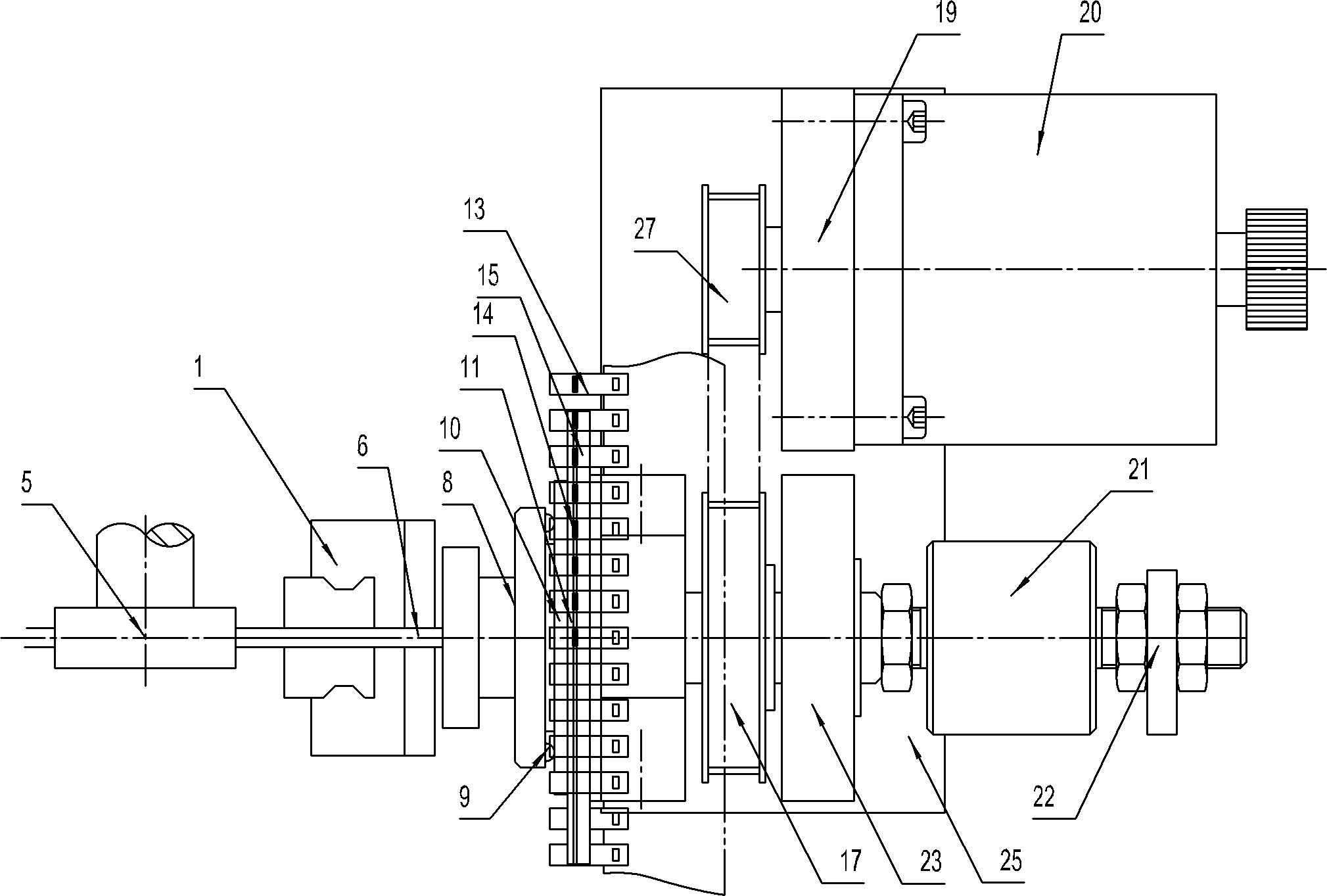

[0016] The present invention will be further described below in conjunction with specific drawings and embodiments.

[0017] As shown in the figure: the plate-type solid aluminum capacitor anode gasket welding wheel mechanism mainly includes two parts: a gasket cutting mechanism and a gasket conveying and welding mechanism, and the gasket cutting mechanism is used to transport the gasket from the conveying wheel 5 The strip 6 is cut into pieces of gaskets, and the gasket delivery and welding mechanism is used to deliver the cut gaskets to the welding position, and weld the gaskets on the aluminum sheet 13 of the capacitor.

[0018] The structure of the gasket cutting mechanism is as follows: Figure 1~Figure 3 As shown, it mainly includes two parts, the fixed cutter 7 and the movable cutter assembly, the fixed cutter 7 is fixedly arranged above the gasket strip 6, and the movable cutter assembly is arranged below the gasket strip 6; the movable cutter assembly is mainly compos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com