Patents

Literature

54results about How to "Realize mechanical automation production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

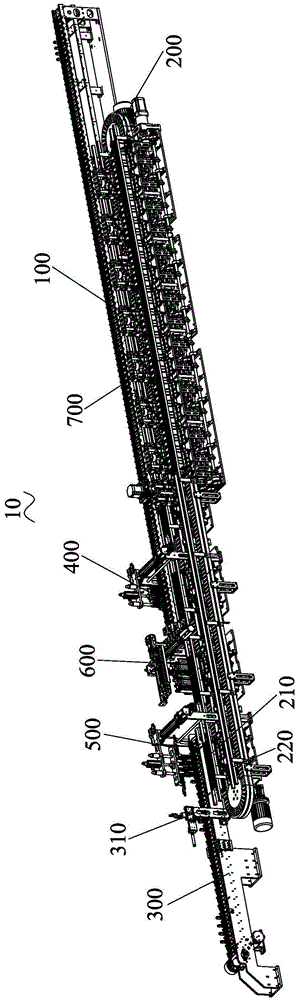

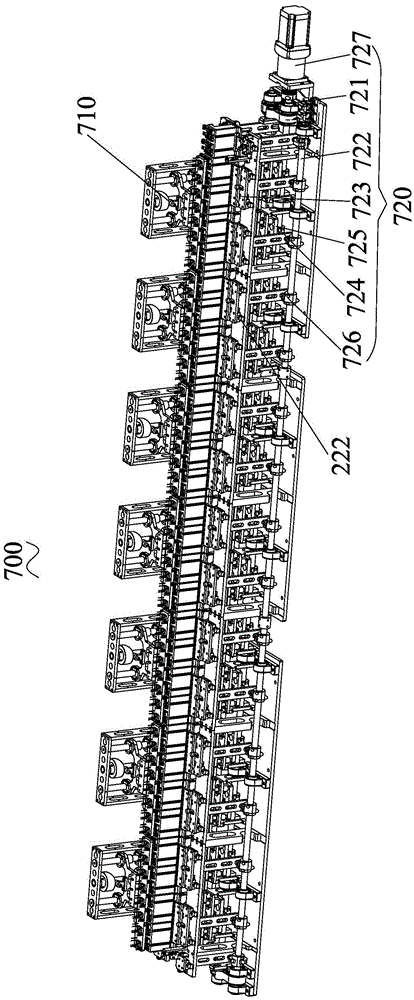

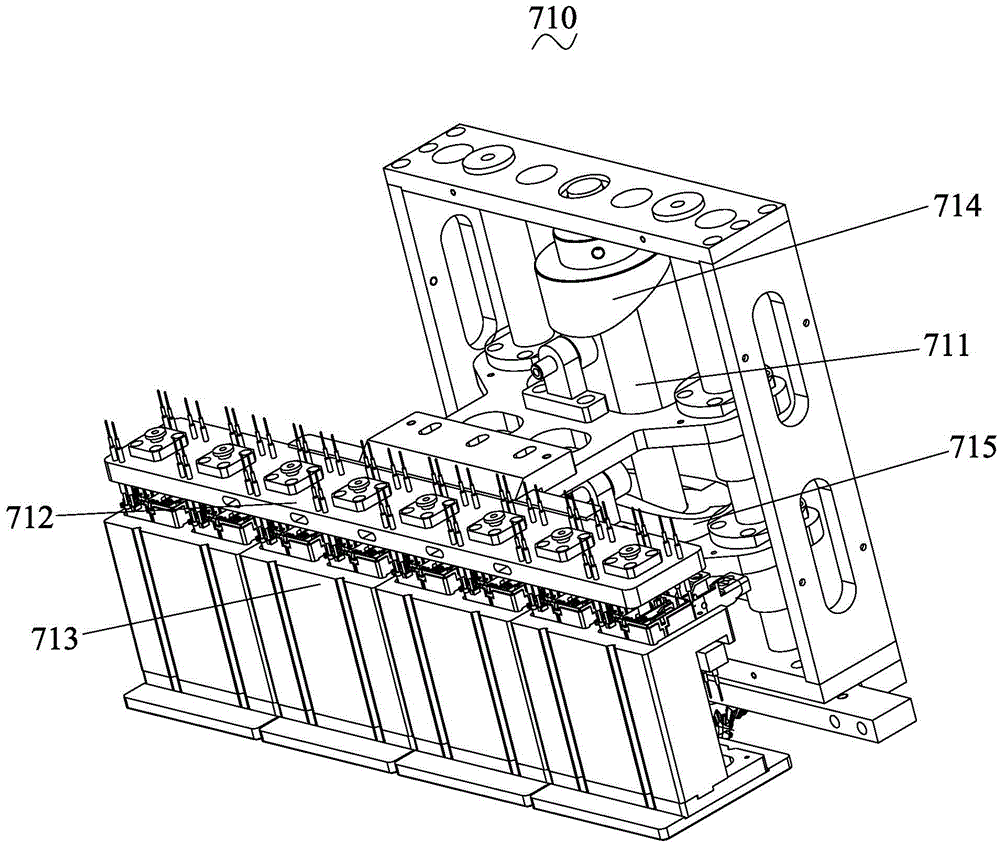

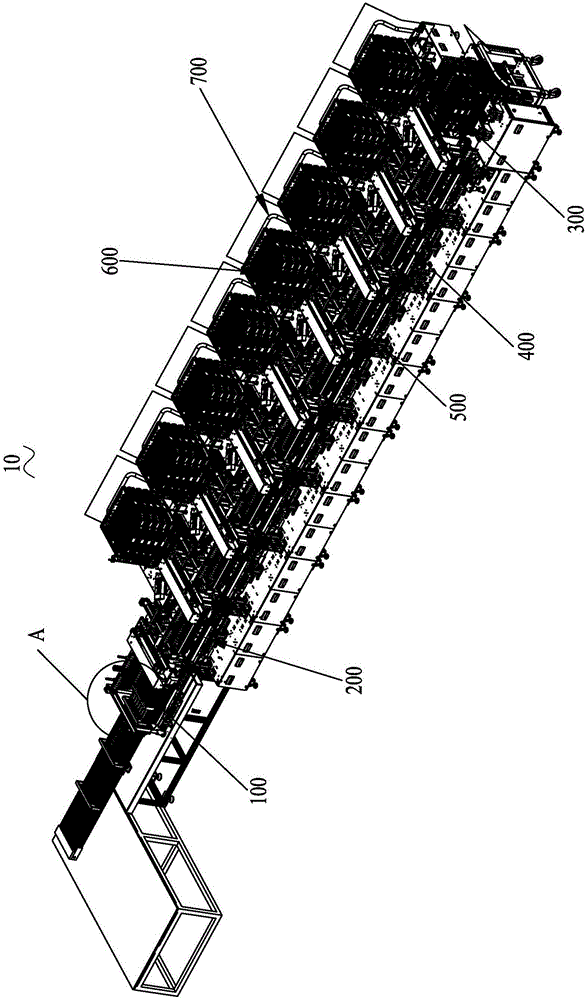

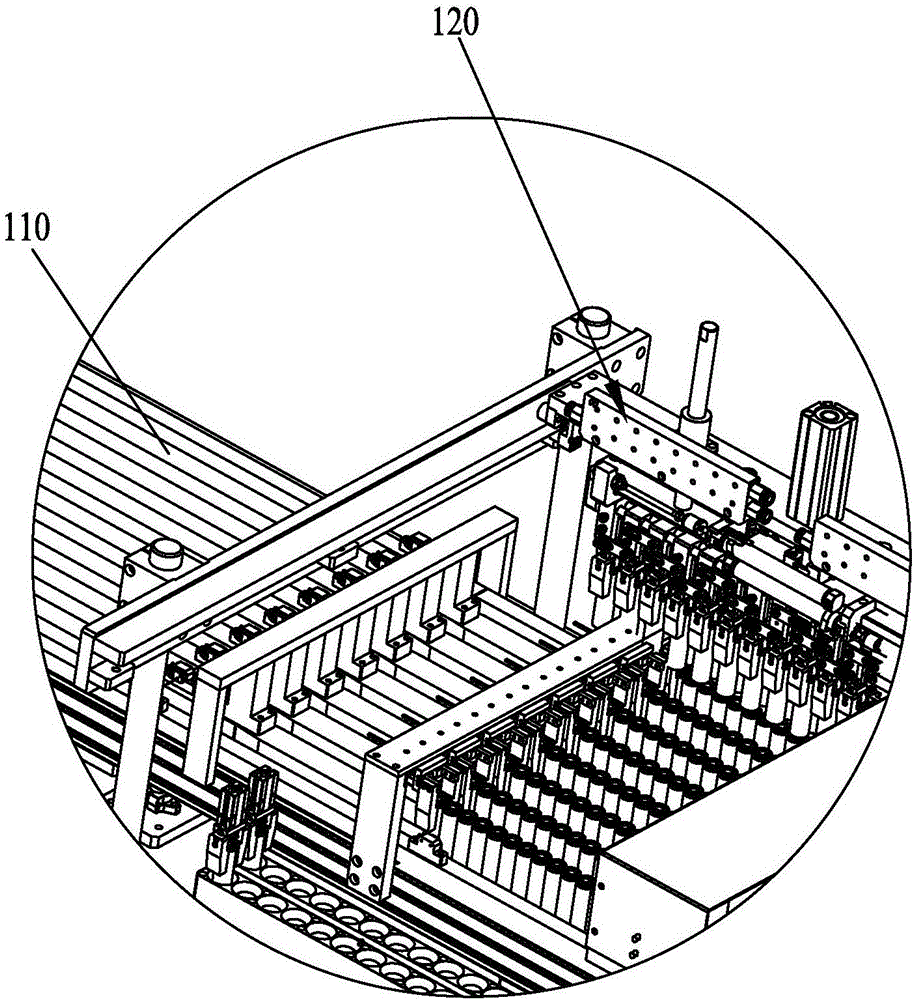

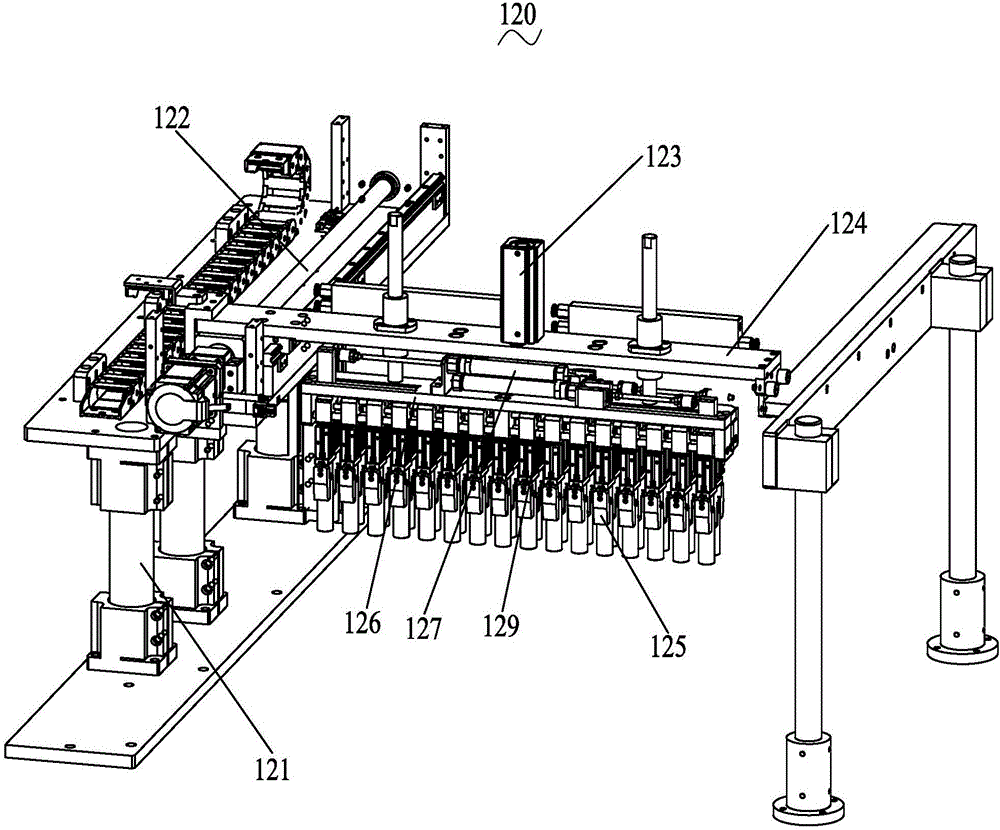

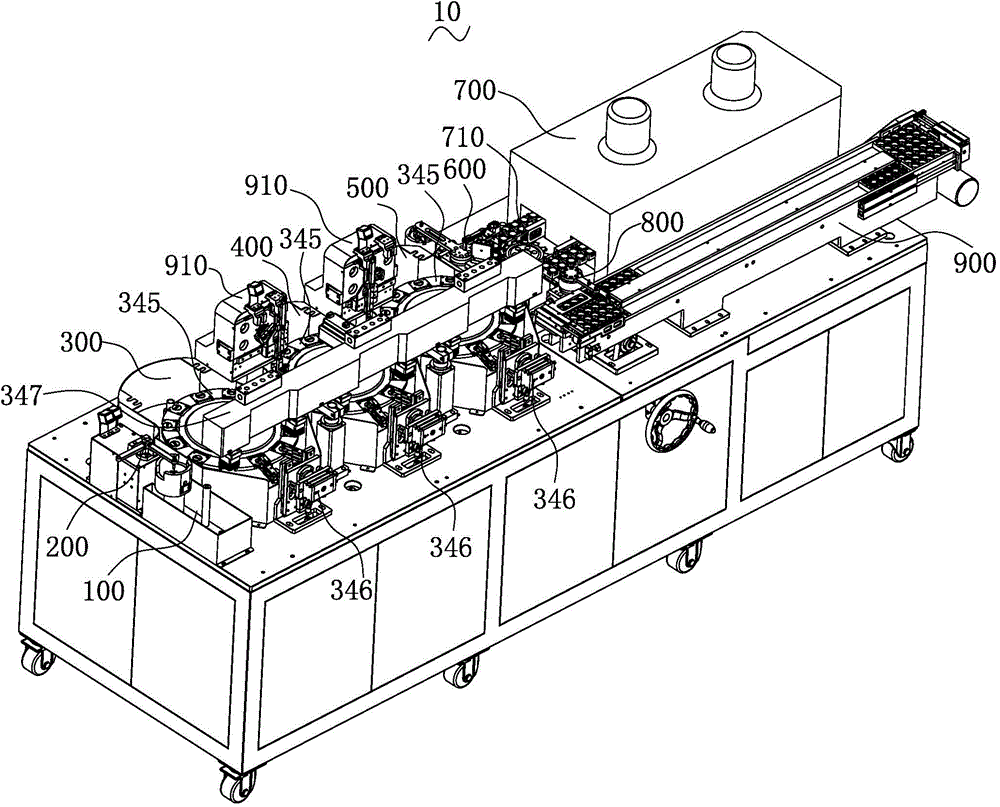

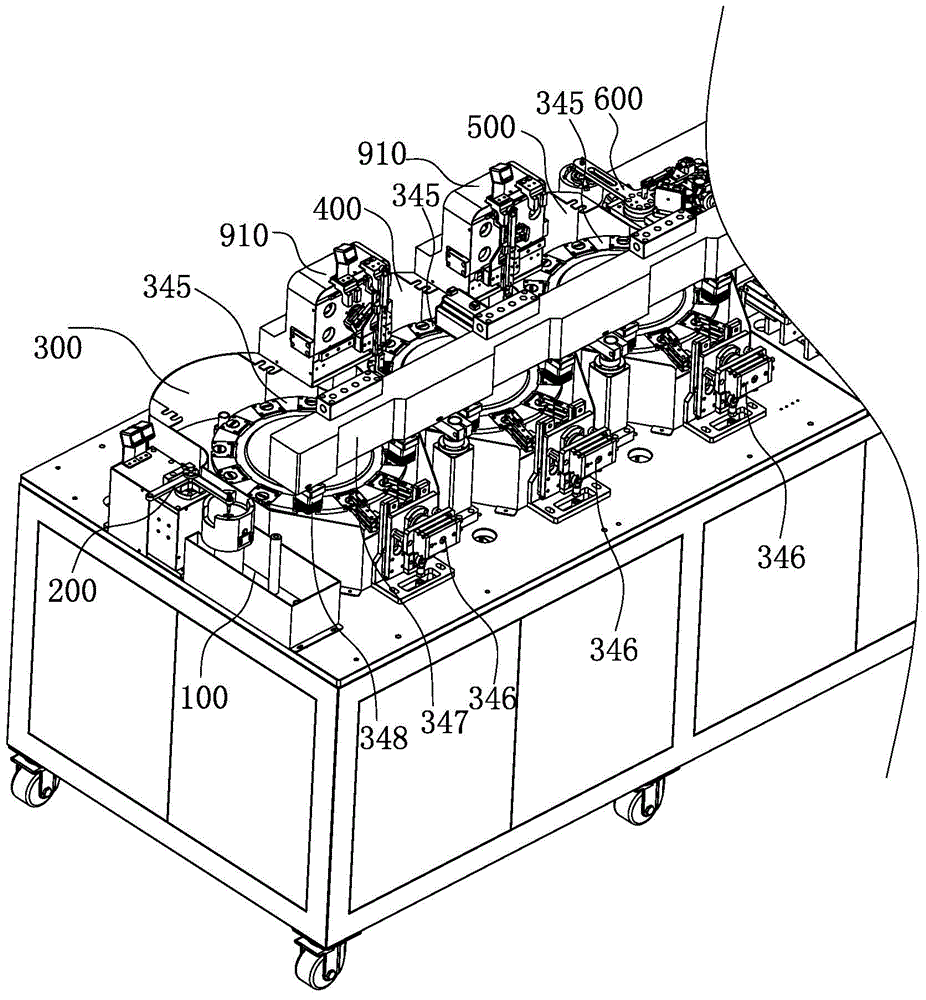

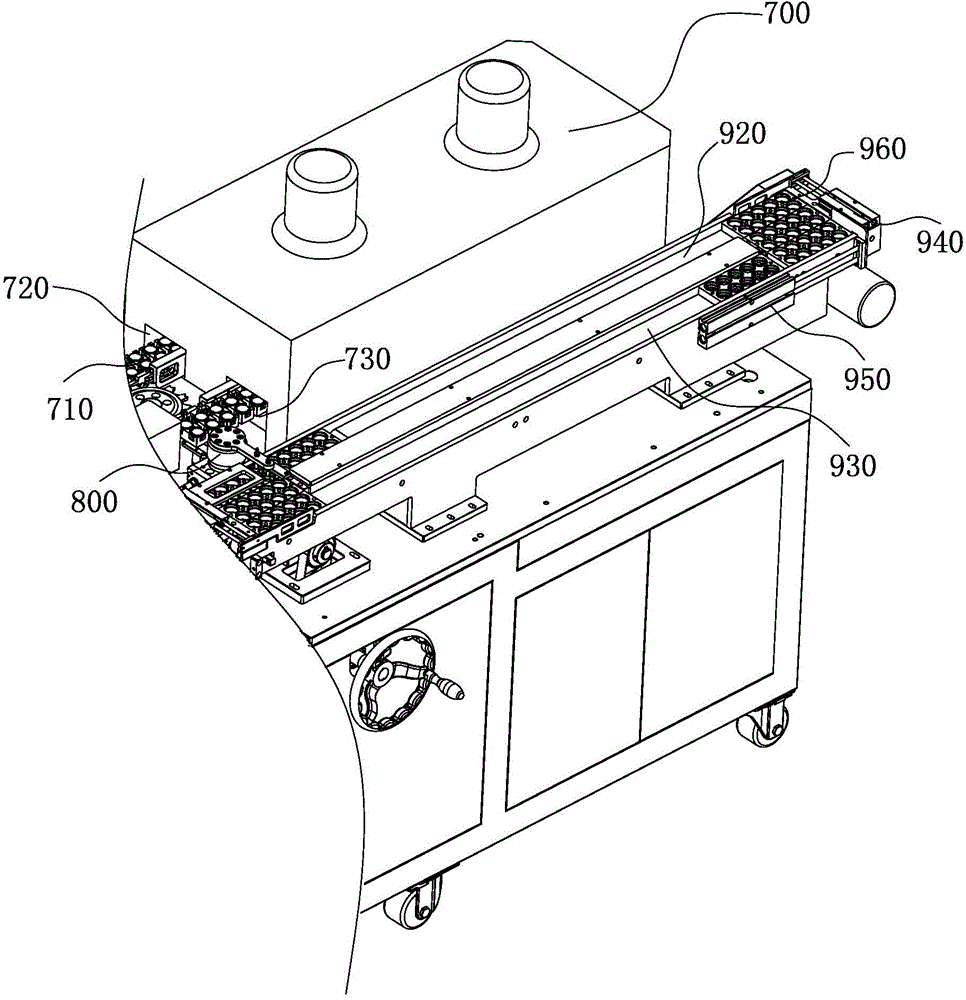

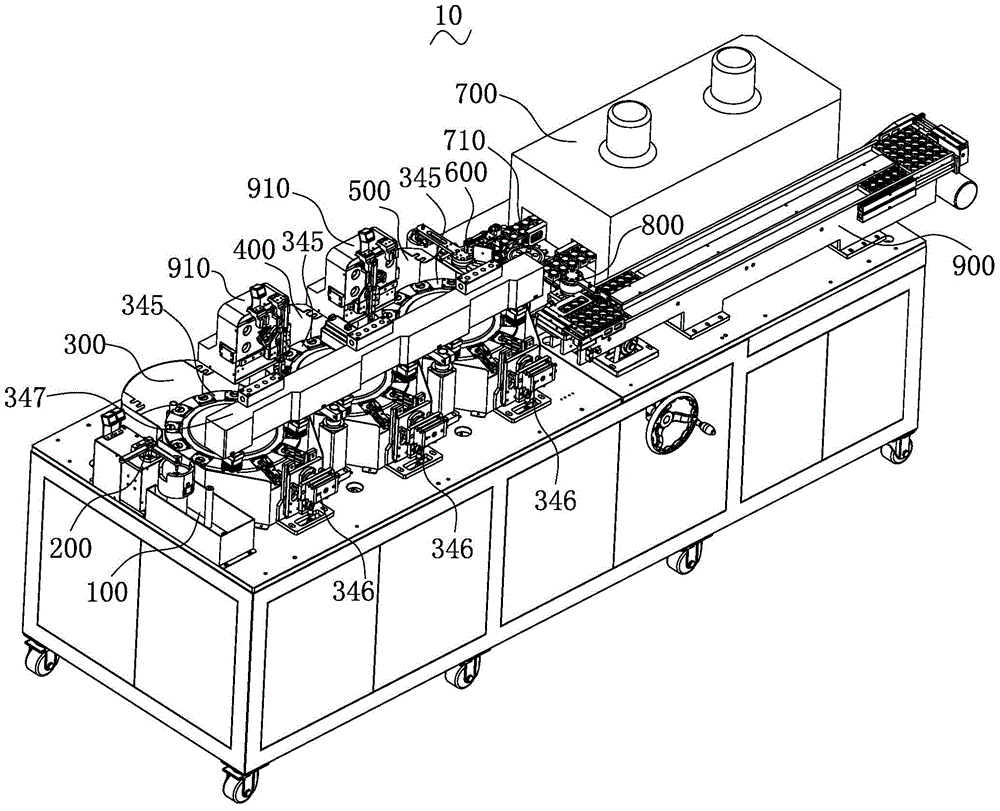

Relay aging tester

ActiveCN105589036ARealize mechanical automation productionCircuit interrupters testingFixed frameSoftware engineering

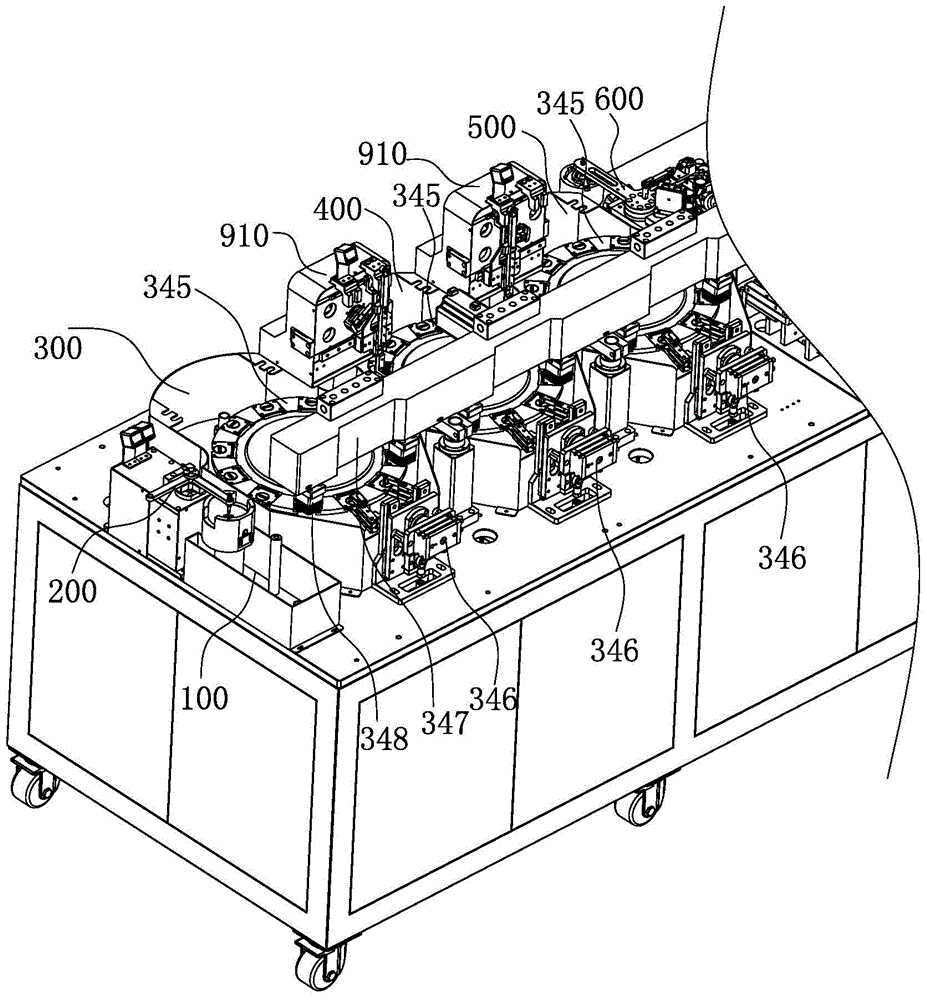

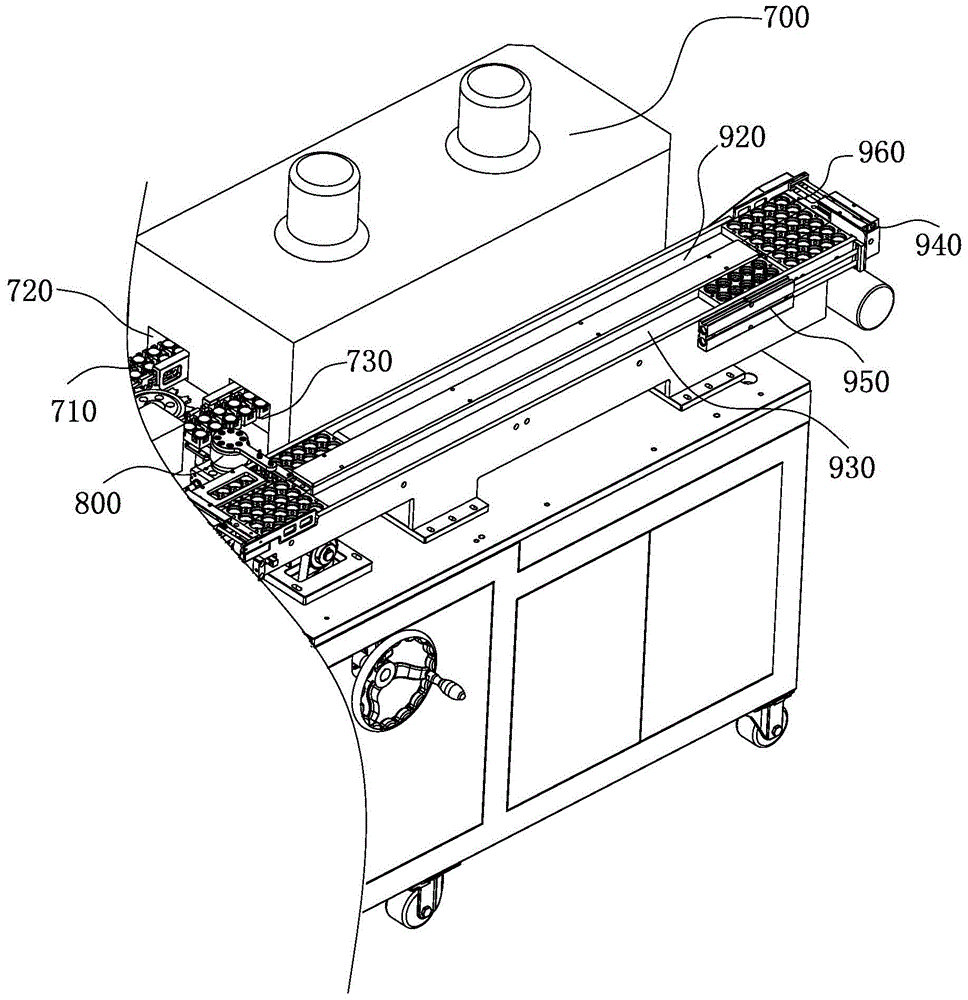

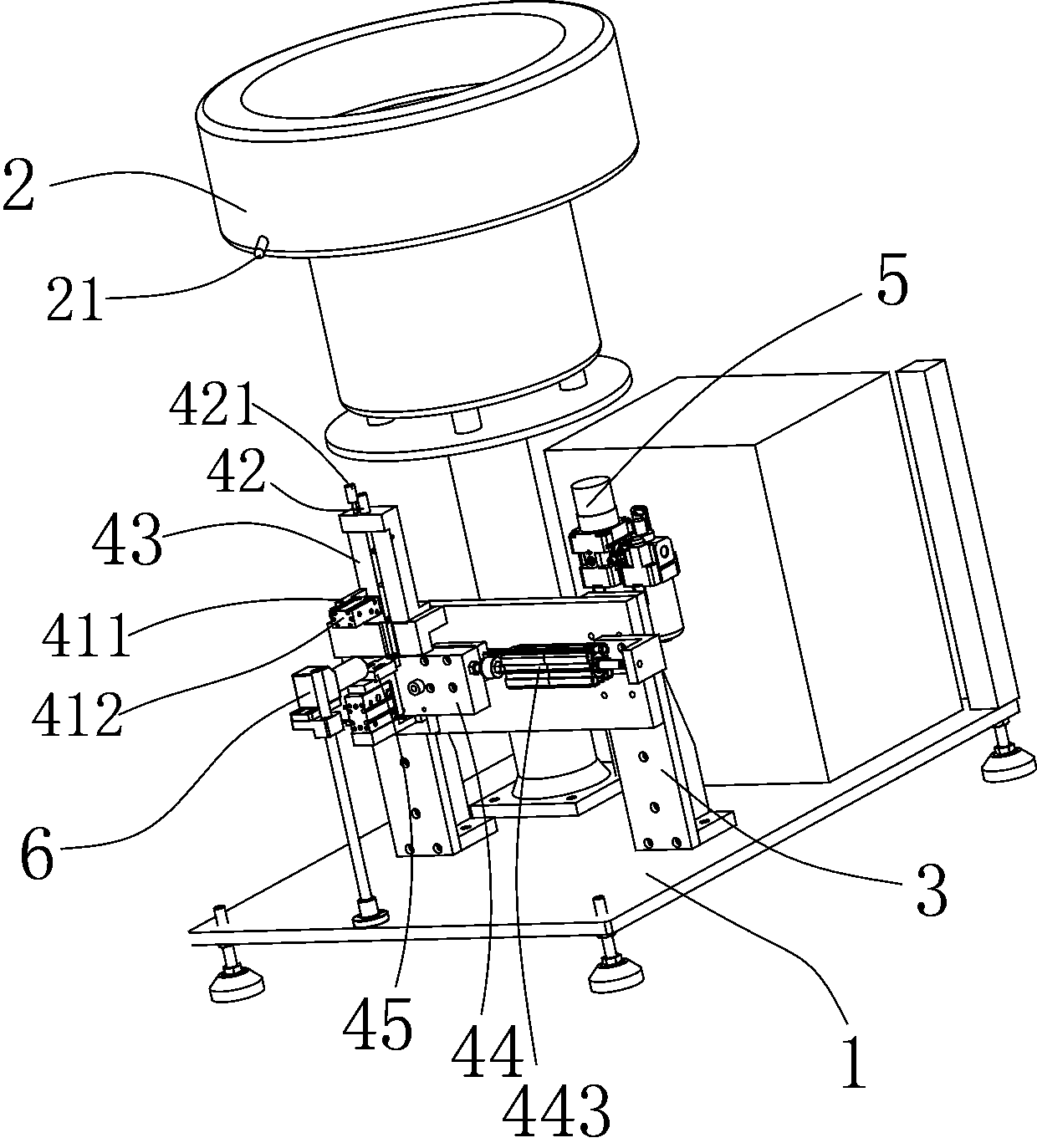

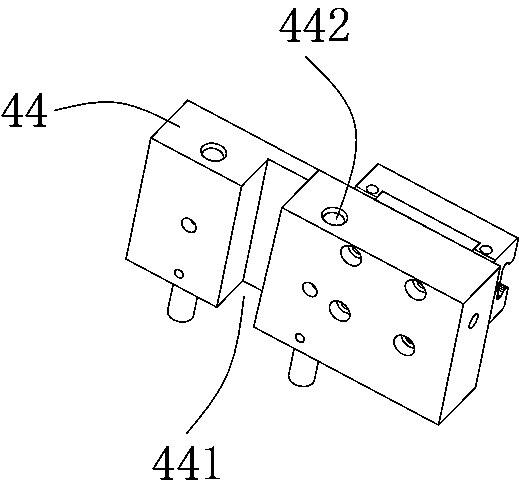

The invention discloses a relay aging tester comprising a feeding line, an annular test line, a blanking line, a feeding manipulator, and a non-defective product fetching manipulator. The feeding manipulator is connected between the feeding line and the annular test line. The non-defective product fetching manipulator is connected between the blanking line and the annular test line. A jig and a fixing frame which is used for fixing the jig are placed on the annular test line. The annular test line is provided with an aging test mechanism which comprises an aging test device and a jig clamping and lifting device. In particular, by installation of the fixing frame for fixing the jig on the annular test line, at the same time, by installation of the aging test device and the jig clamping and lifting device on the annular test line, the test stability is increased and the mechanical automation production of relay aging test is realized.

Owner:HUIZHOU JINYUAN PRECISION AUTOMATION EQUIP

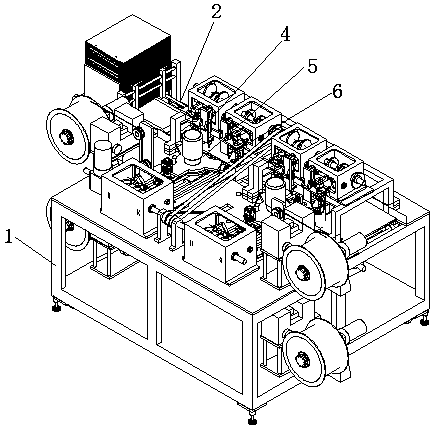

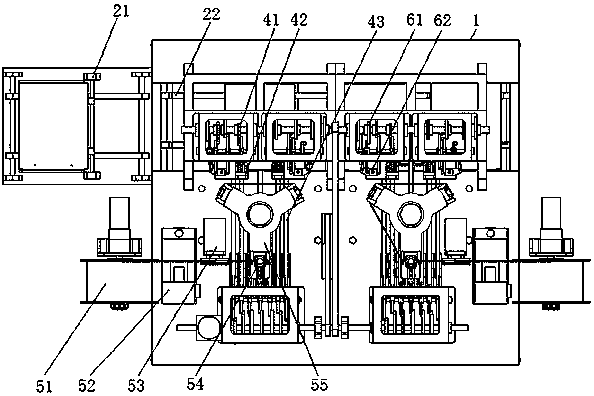

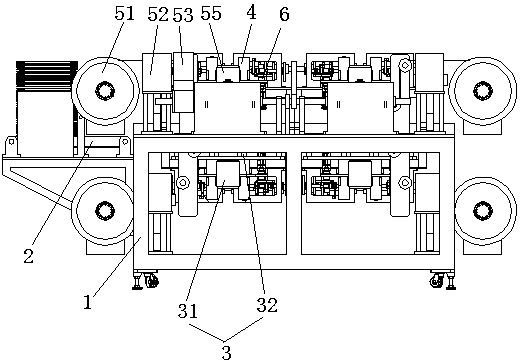

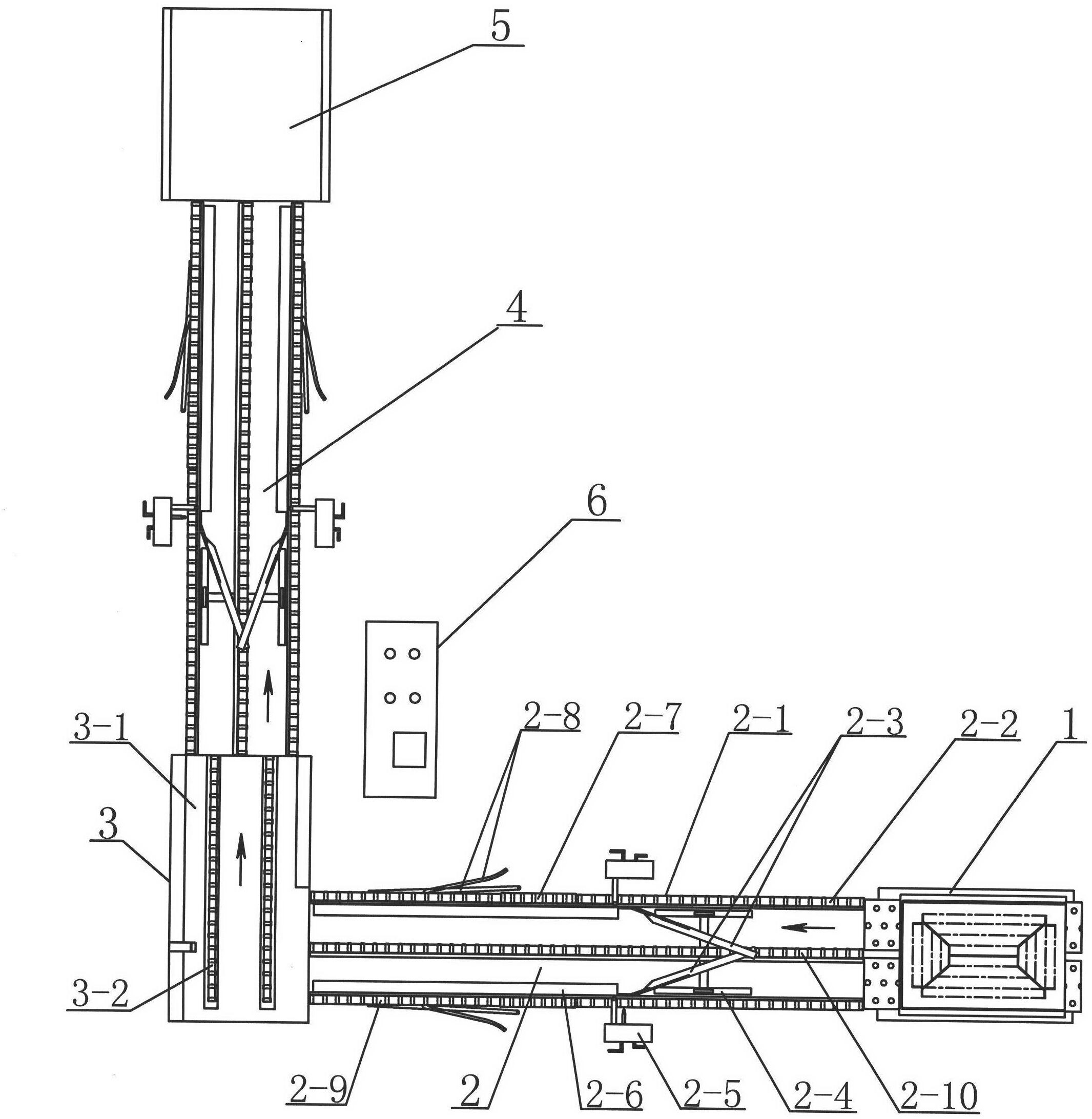

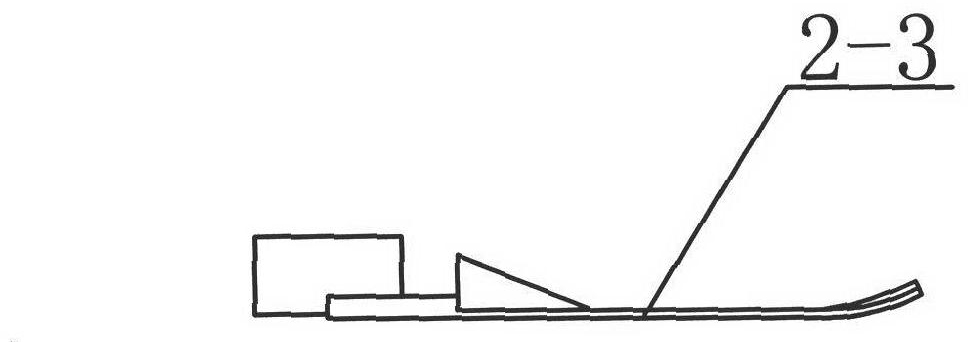

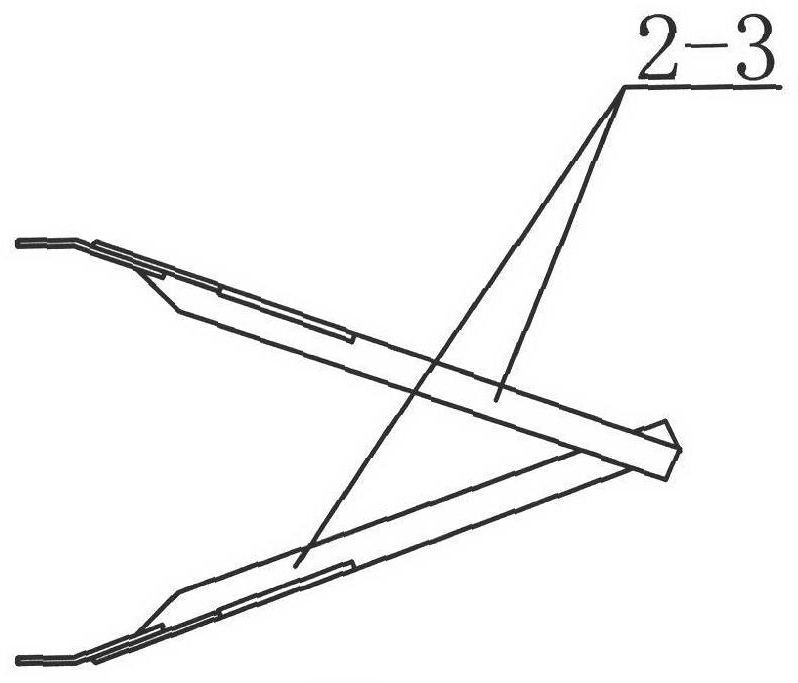

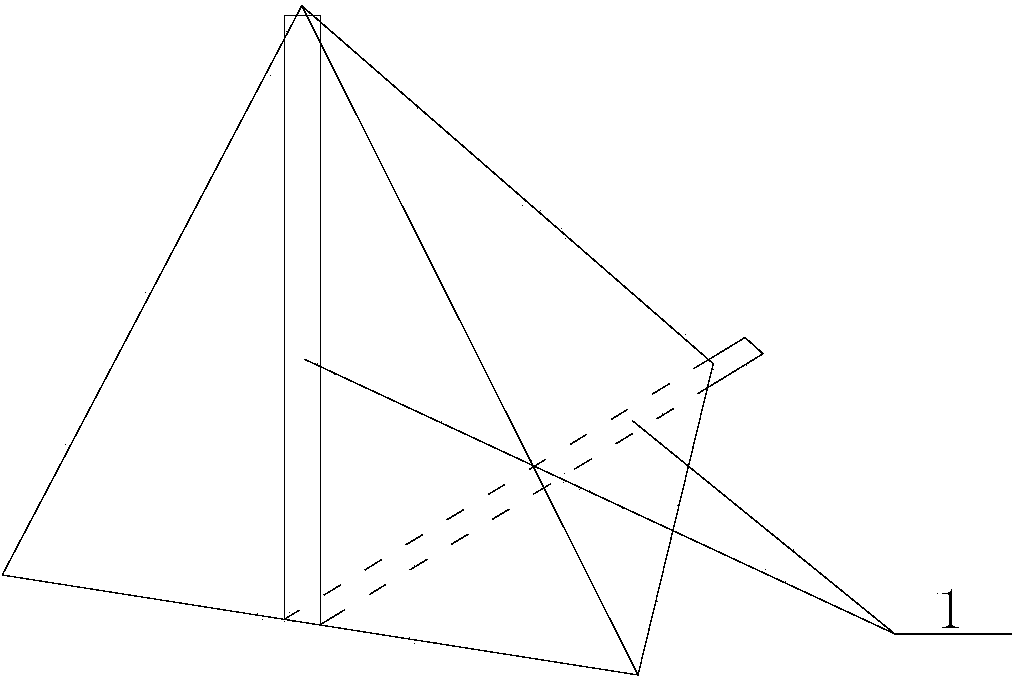

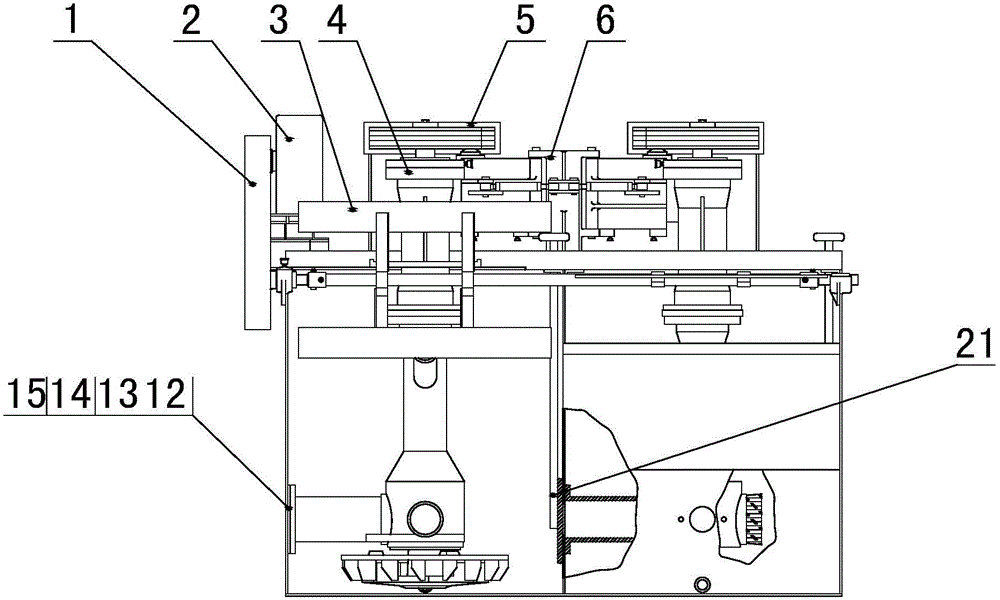

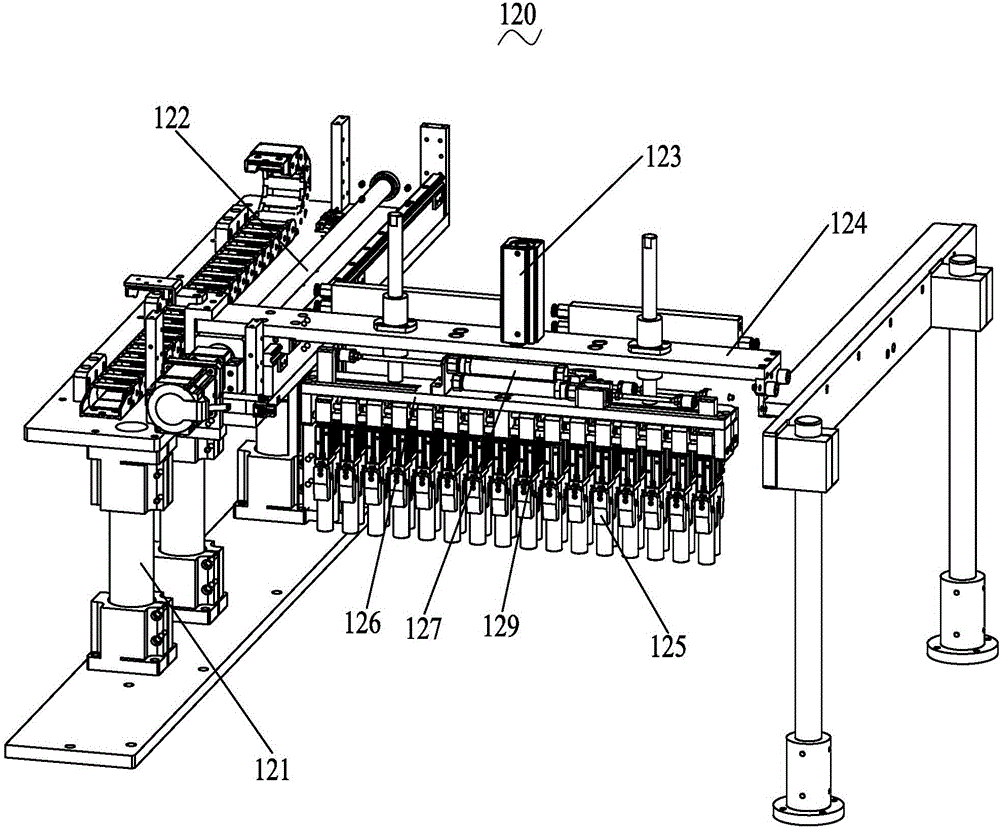

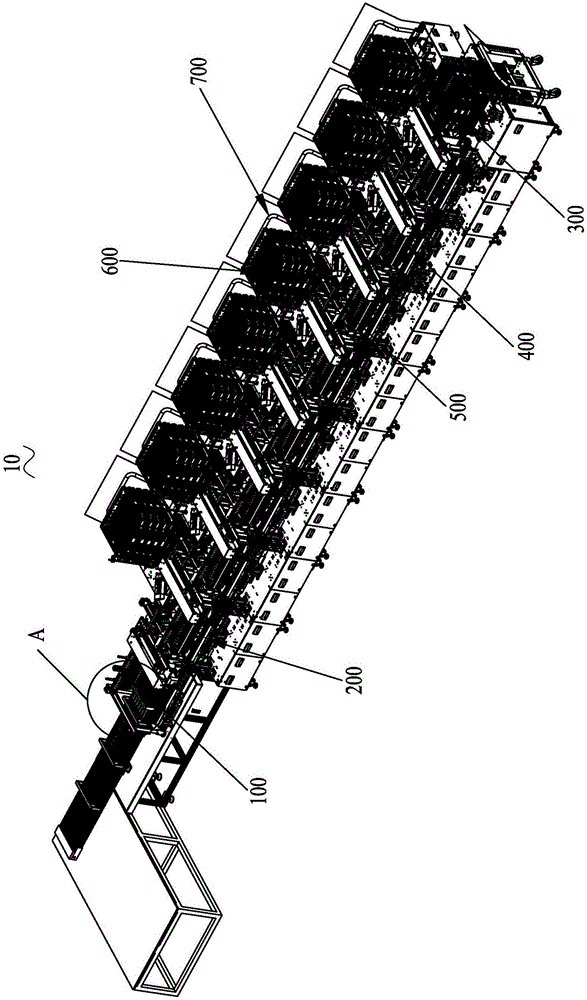

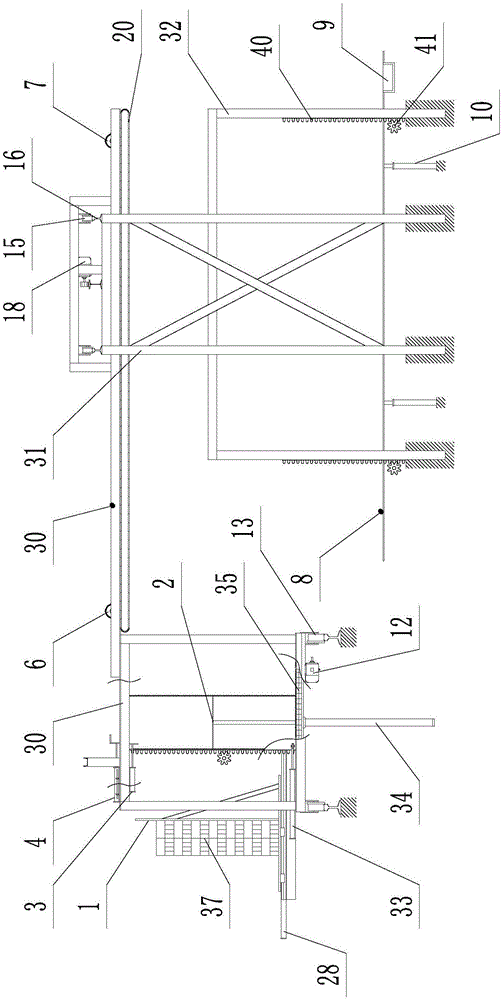

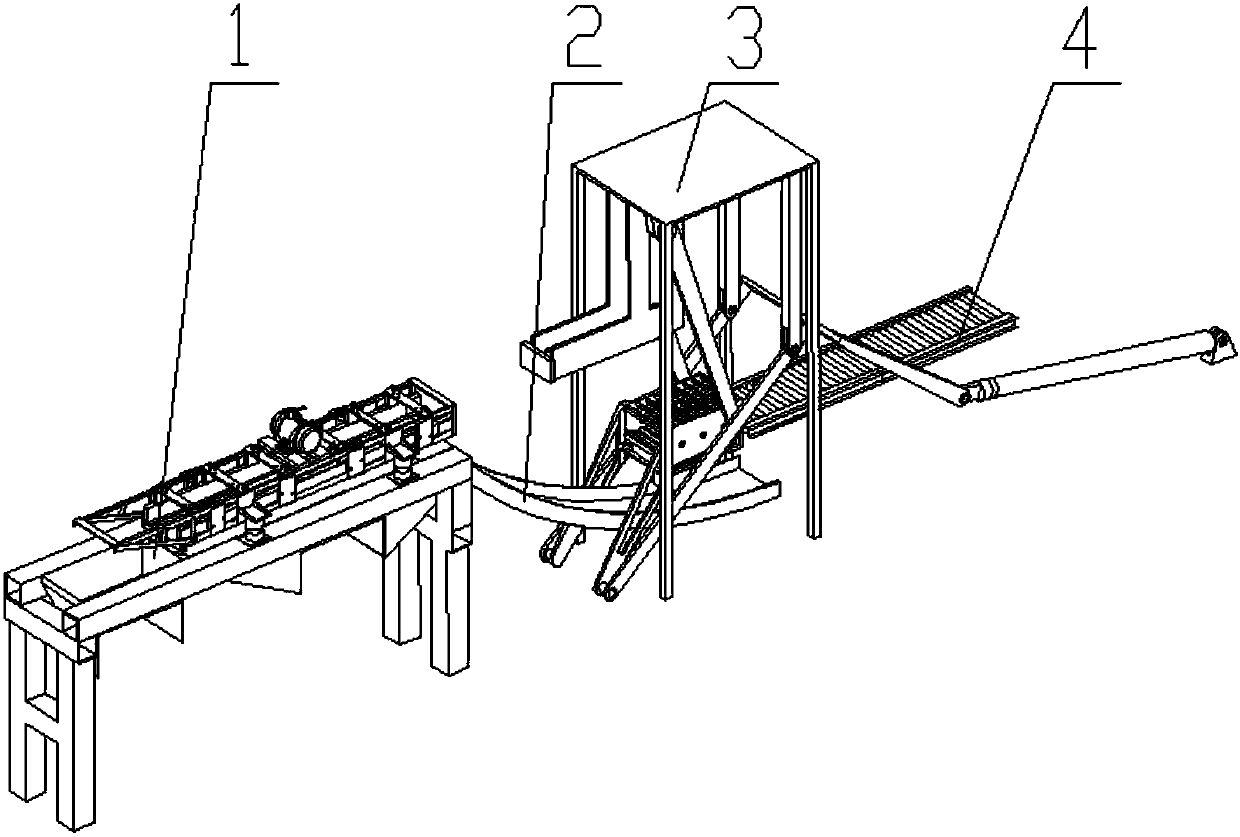

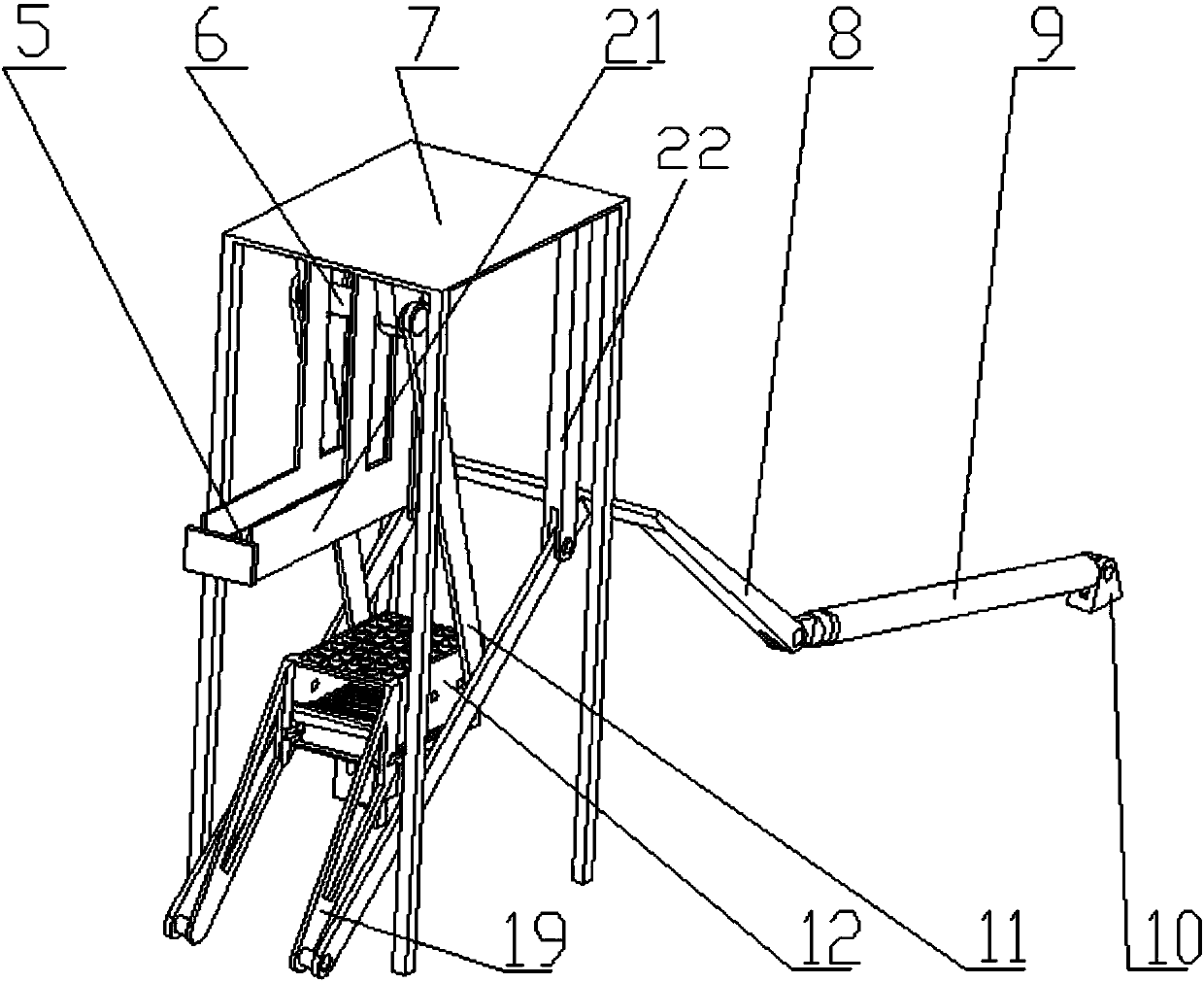

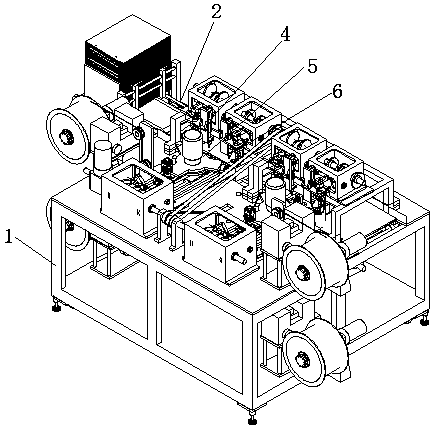

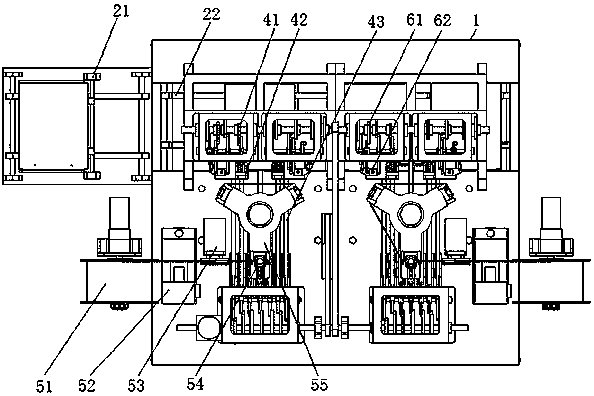

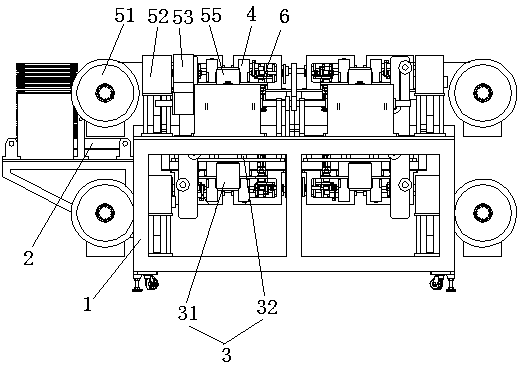

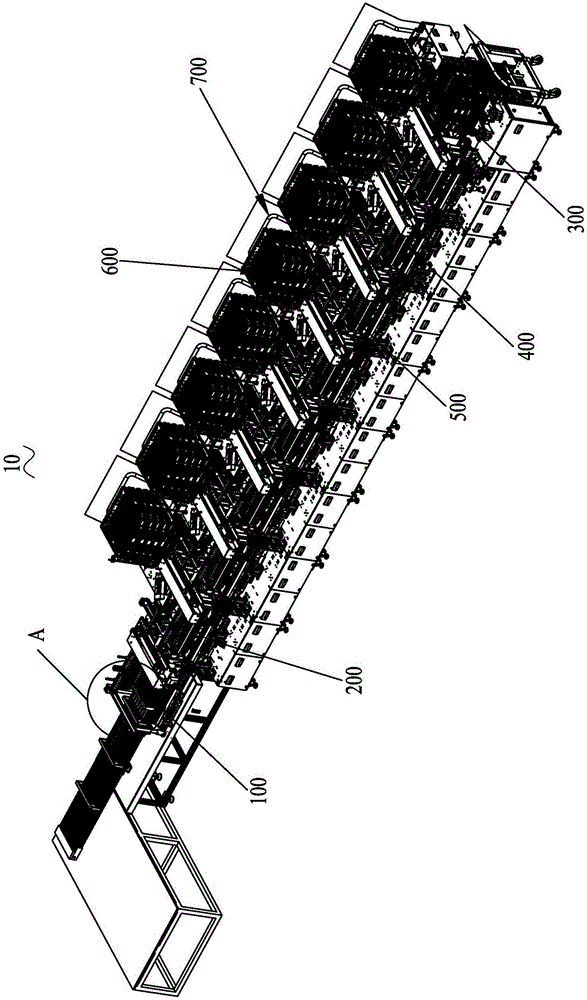

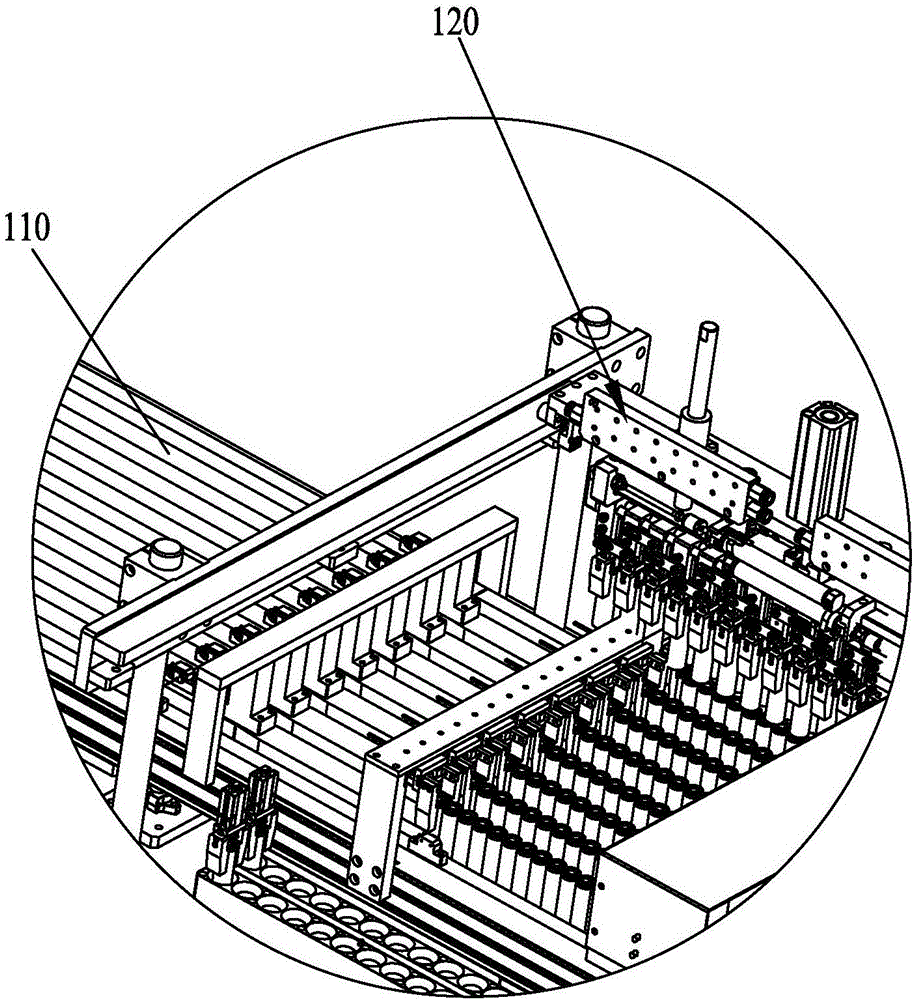

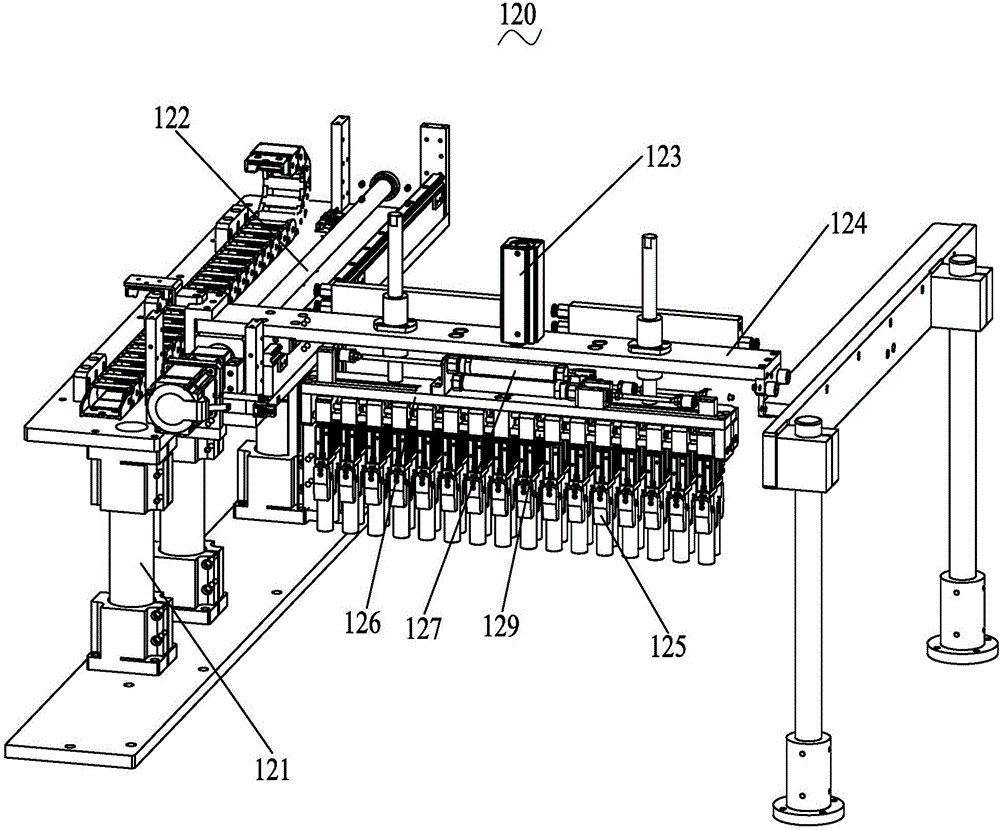

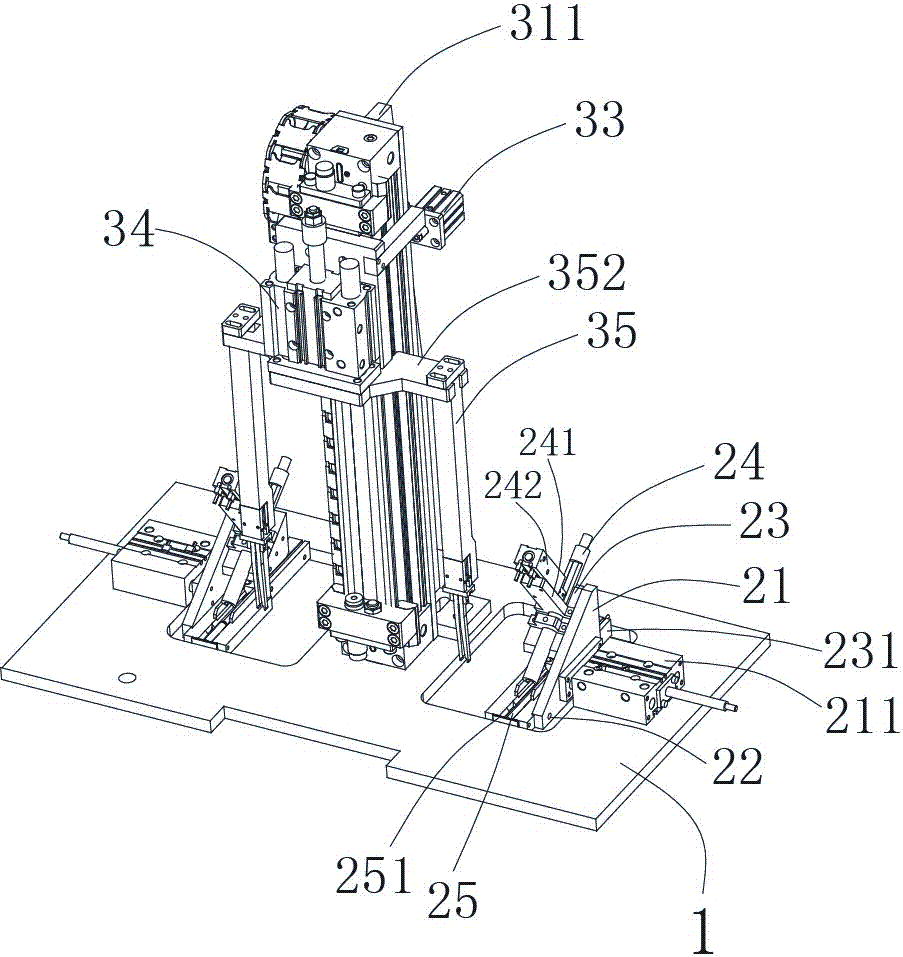

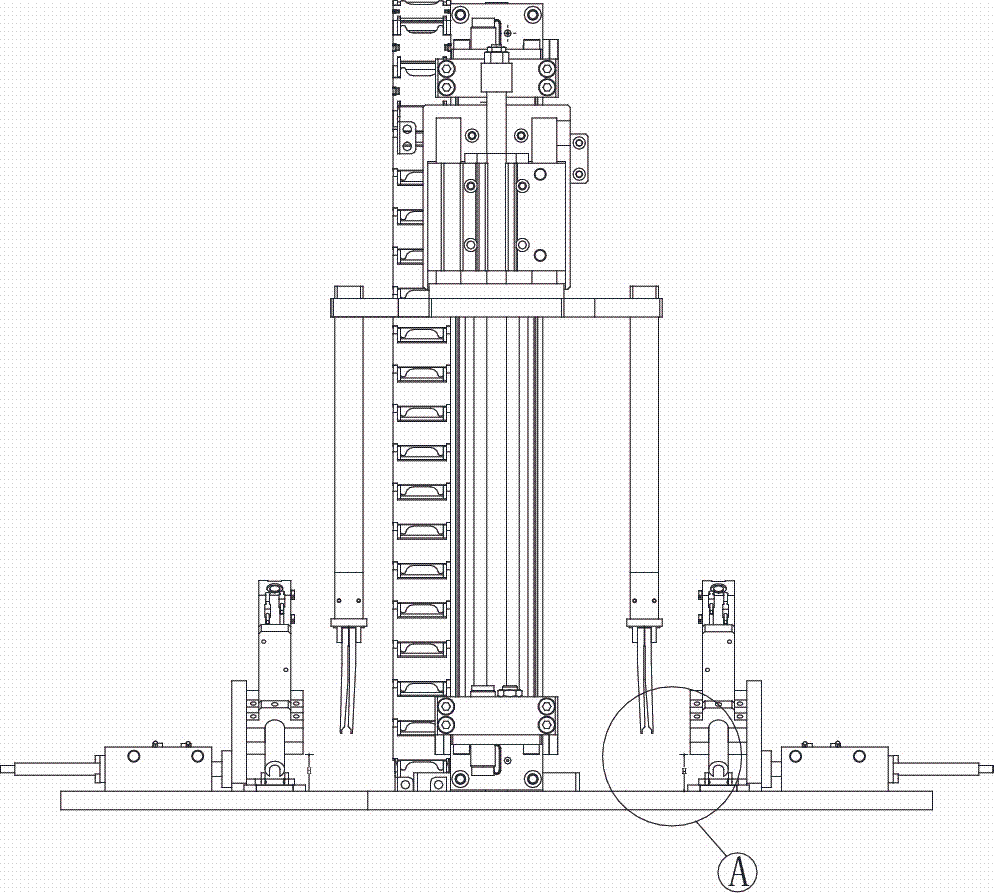

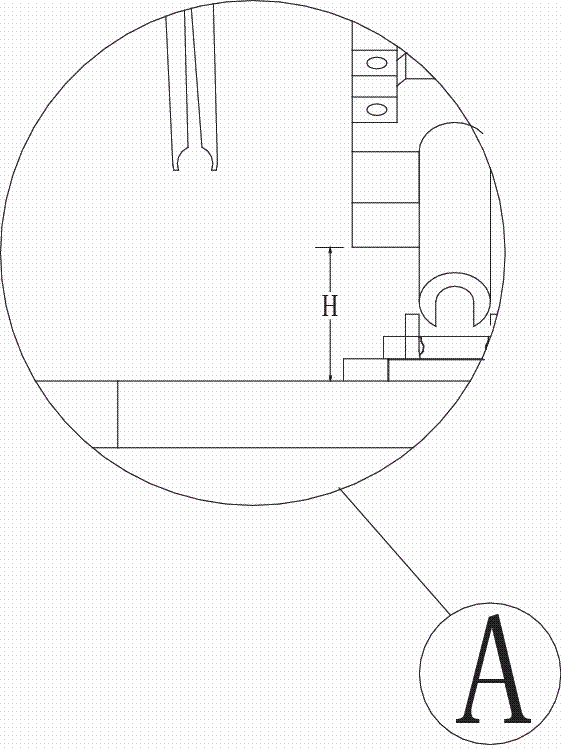

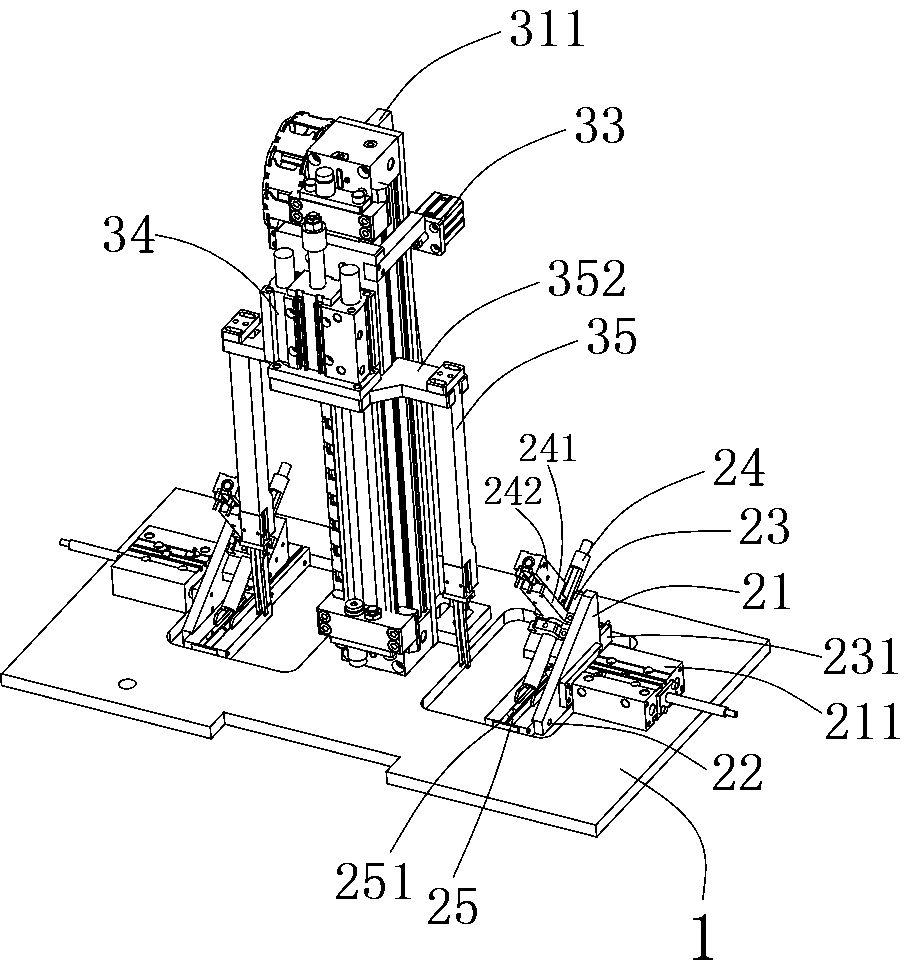

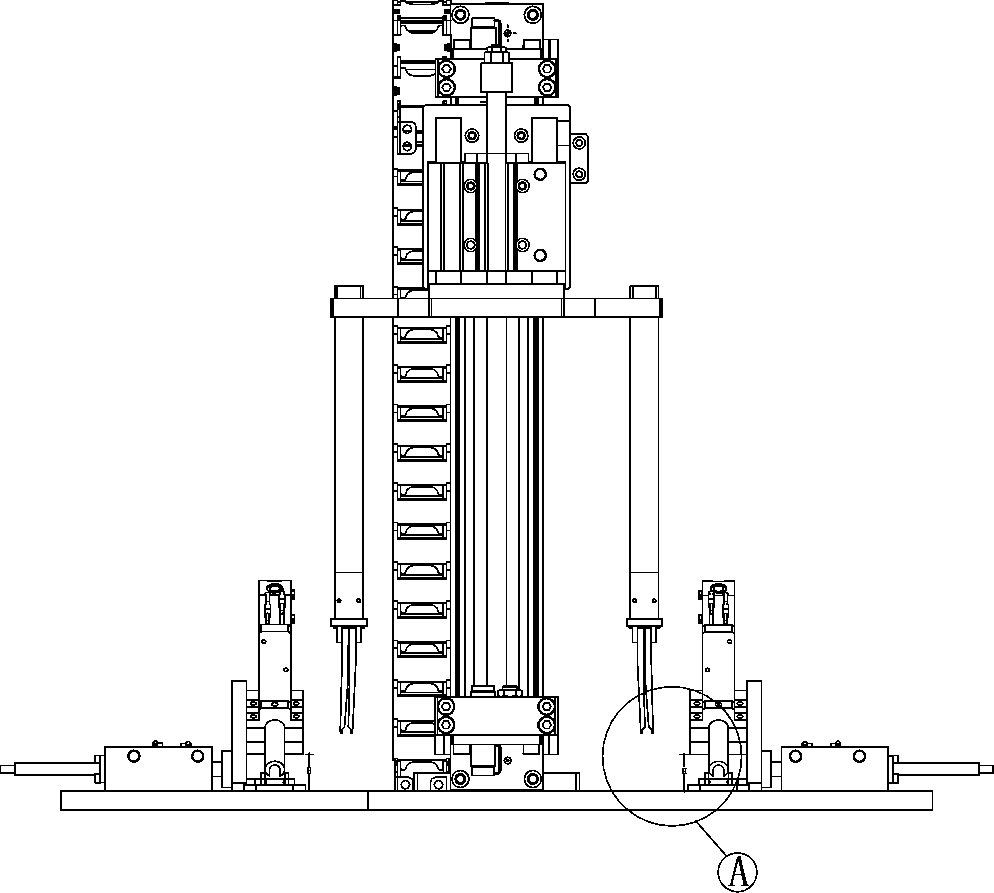

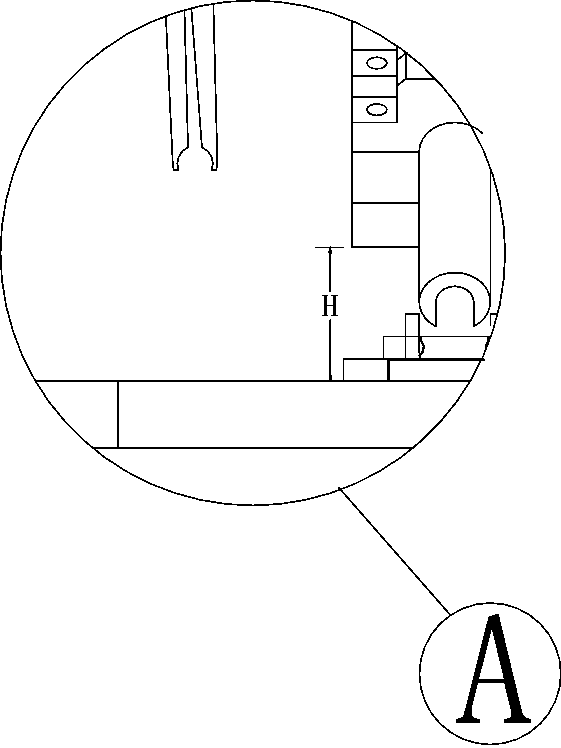

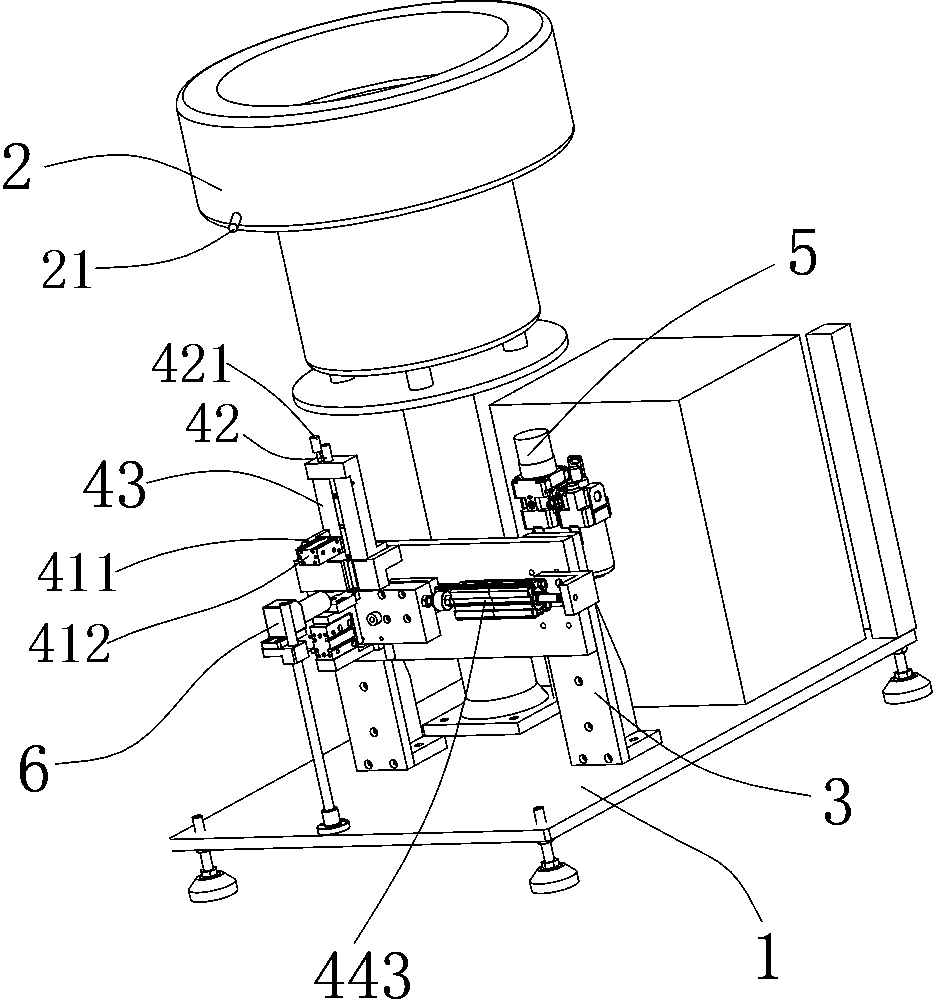

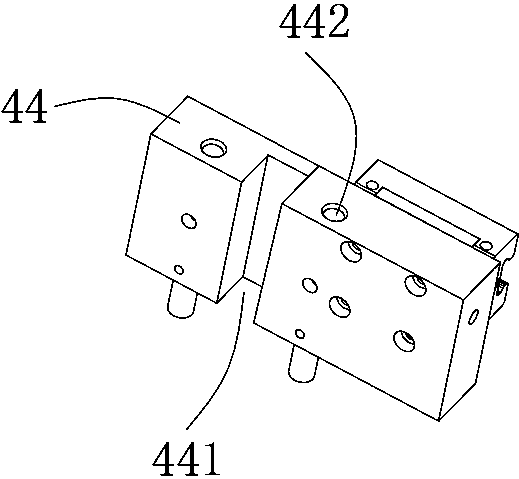

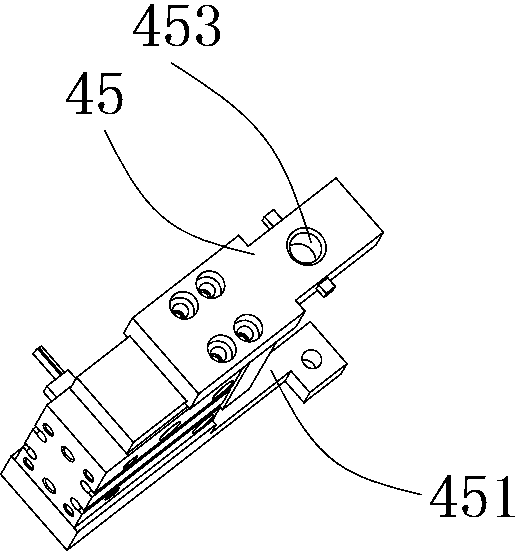

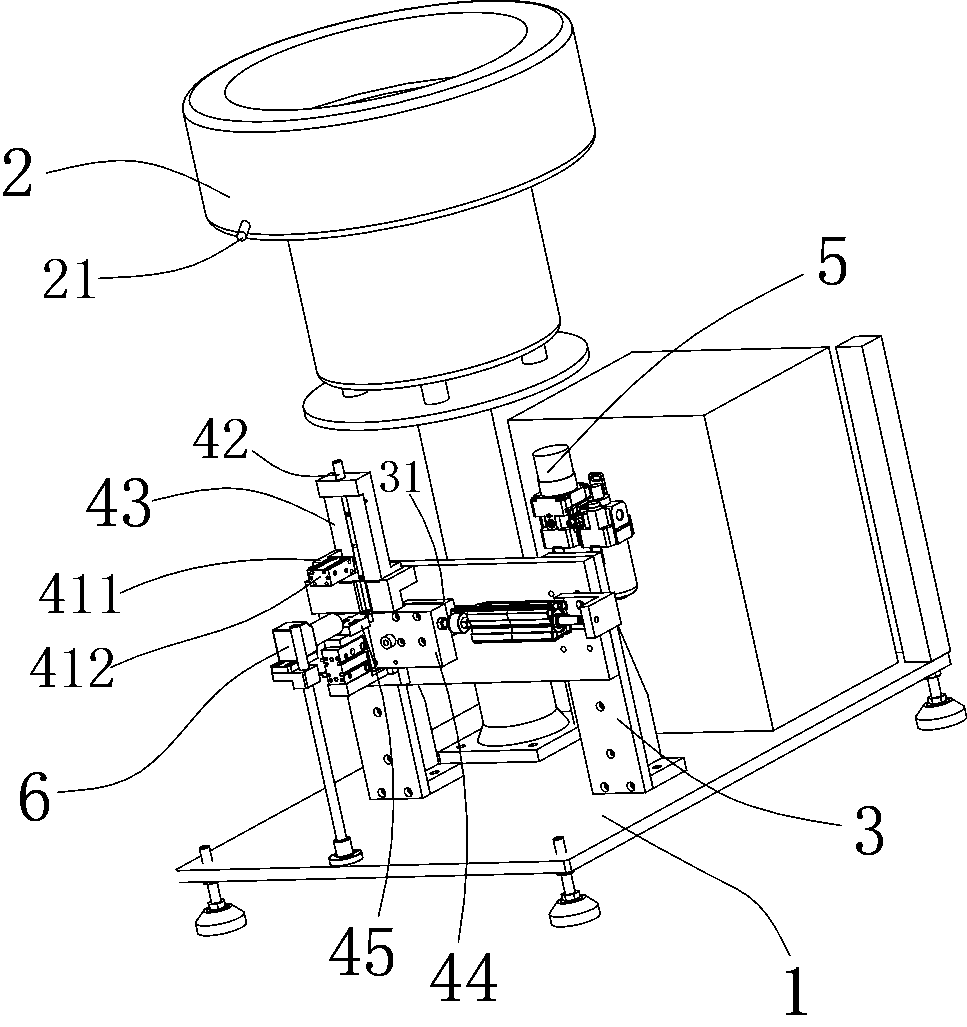

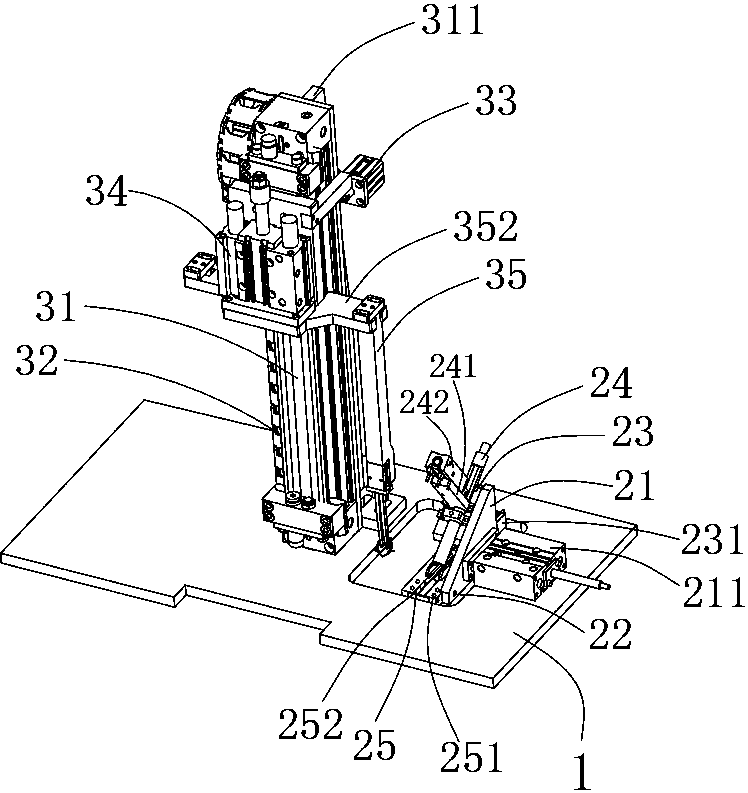

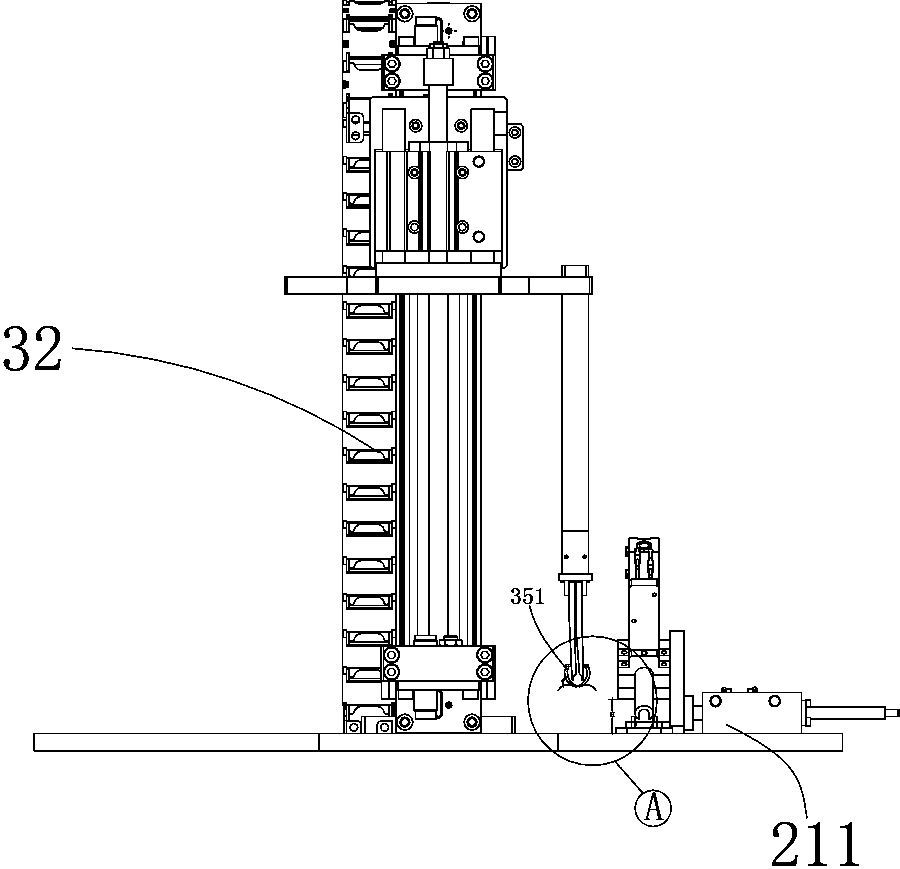

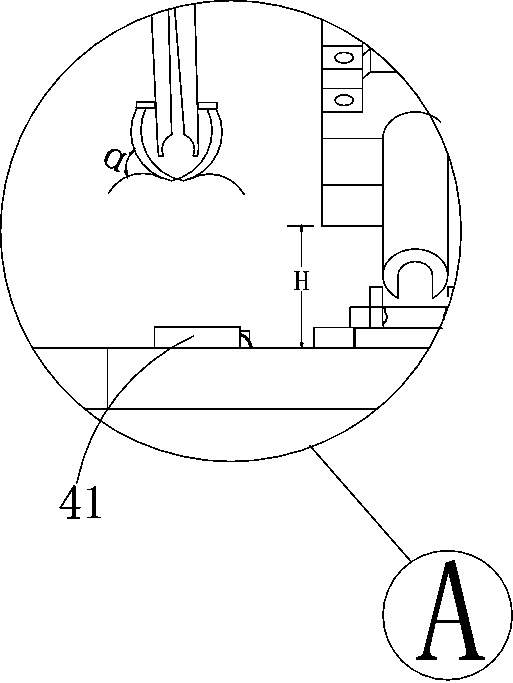

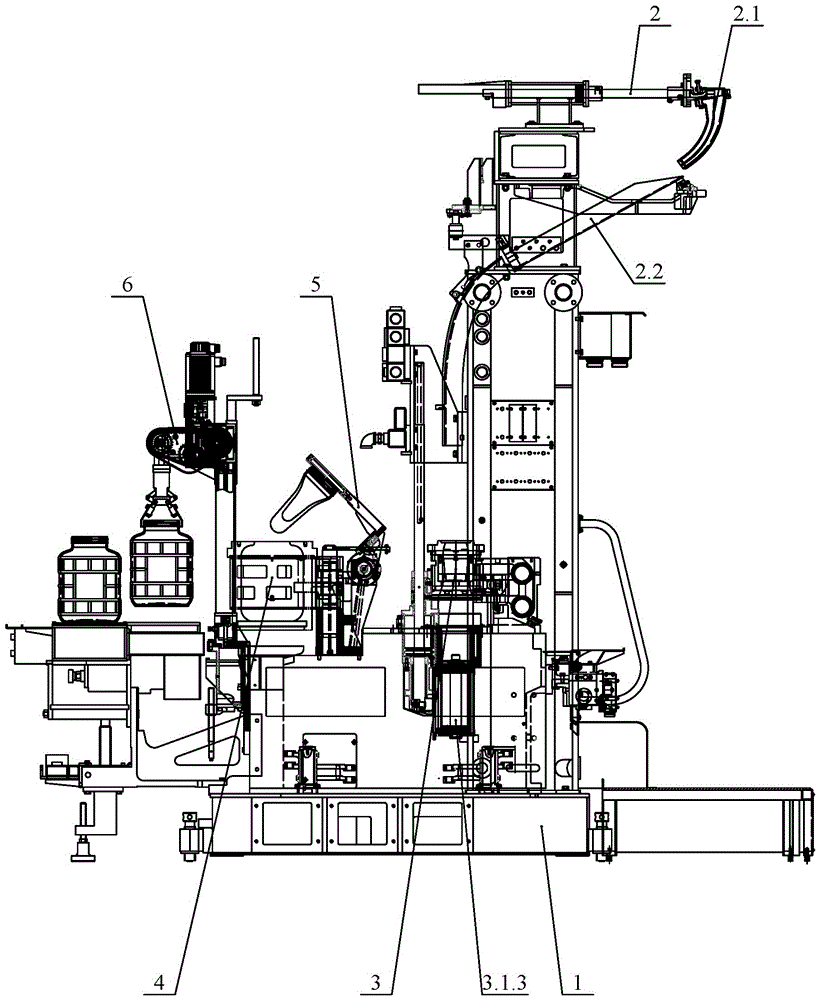

Automatic rope threading equipment for carry bags

ActiveCN106584919ARealize mechanical automation productionIncrease productivityBag making operationsPaper-makingMechanical engineeringEngineering

The invention provides automatic rope threading equipment for carry bags. The equipment comprises a rack; a feeding mechanism, box opening mechanisms, perforating mechanisms, rope conveying mechanisms and rope threading mechanisms are arranged on the rack; the feeding mechanism penetrates through the box opening mechanisms; each perforating mechanism comprises an upper-layer perforating assembly and a lower-layer perforating assembly which are arranged vertically symmetrically; each rope threading mechanism comprises an upper-layer rope threading assembly and a lower-layer rope threading assembly which are arranged vertically symmetrically; each rope conveying mechanism comprises an upper-layer rope conveying assembly and a lower-layer rope conveying assembly which are arranged vertically symmetrically; the upper-layer rope conveying assemblies correspond to the upper-layer rope threading assemblies; and the lower-layer rope conveying assemblies correspond to the lower-layer rope threading assemblies. With the equipment, multiple procedures such as feeding, box opening, perforating, rope conveying, rope threading and the like are integrated, mechanical and automatic production is realized, the production time is greatly shortened, the production efficiency is improved, the labor cost is reduced, meanwhile, bad products caused by human factors are avoided, the uniformity of products is guaranteed, and the overall yield of the products is increased.

Owner:武汉世豪同创自动化设备有限公司

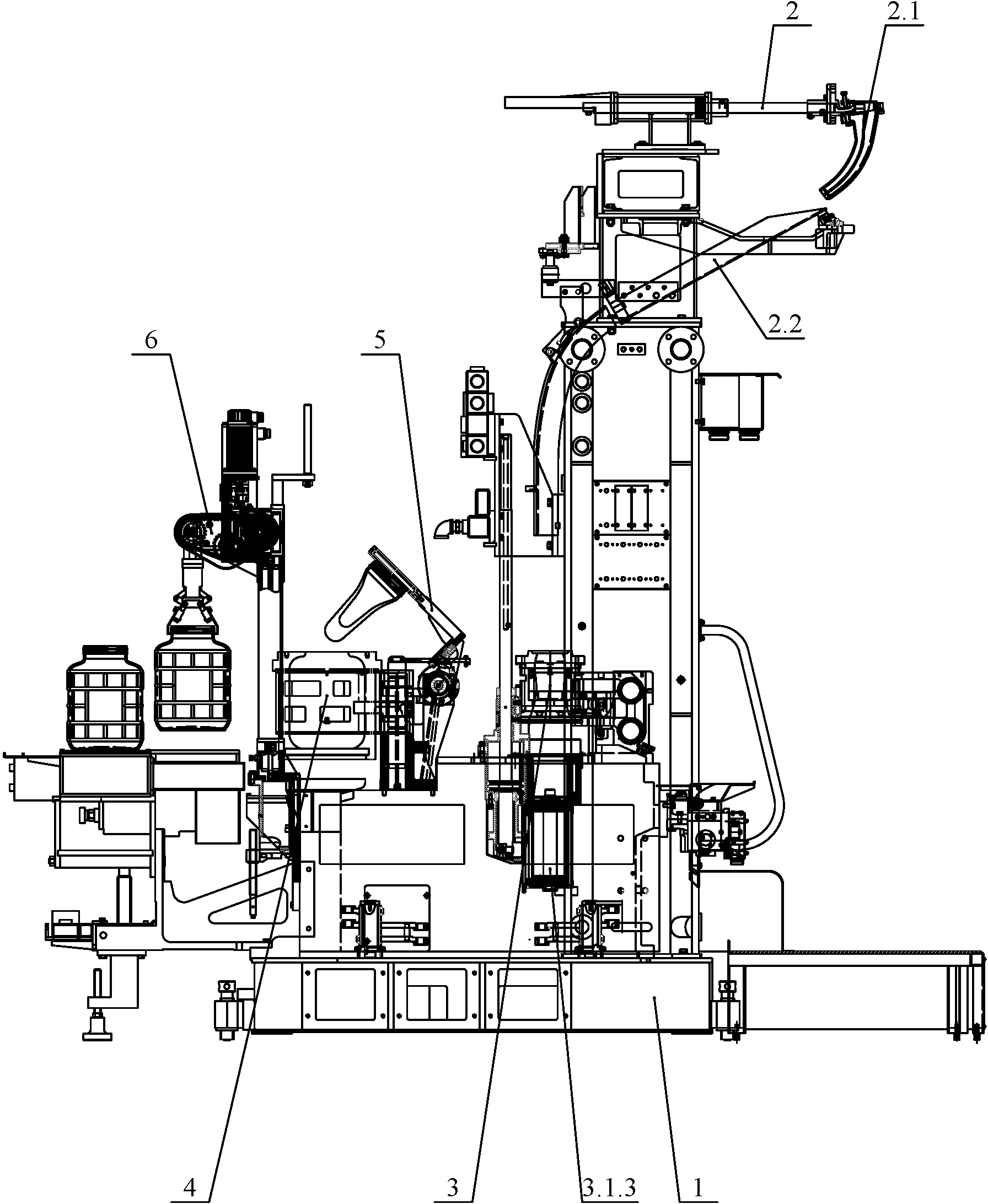

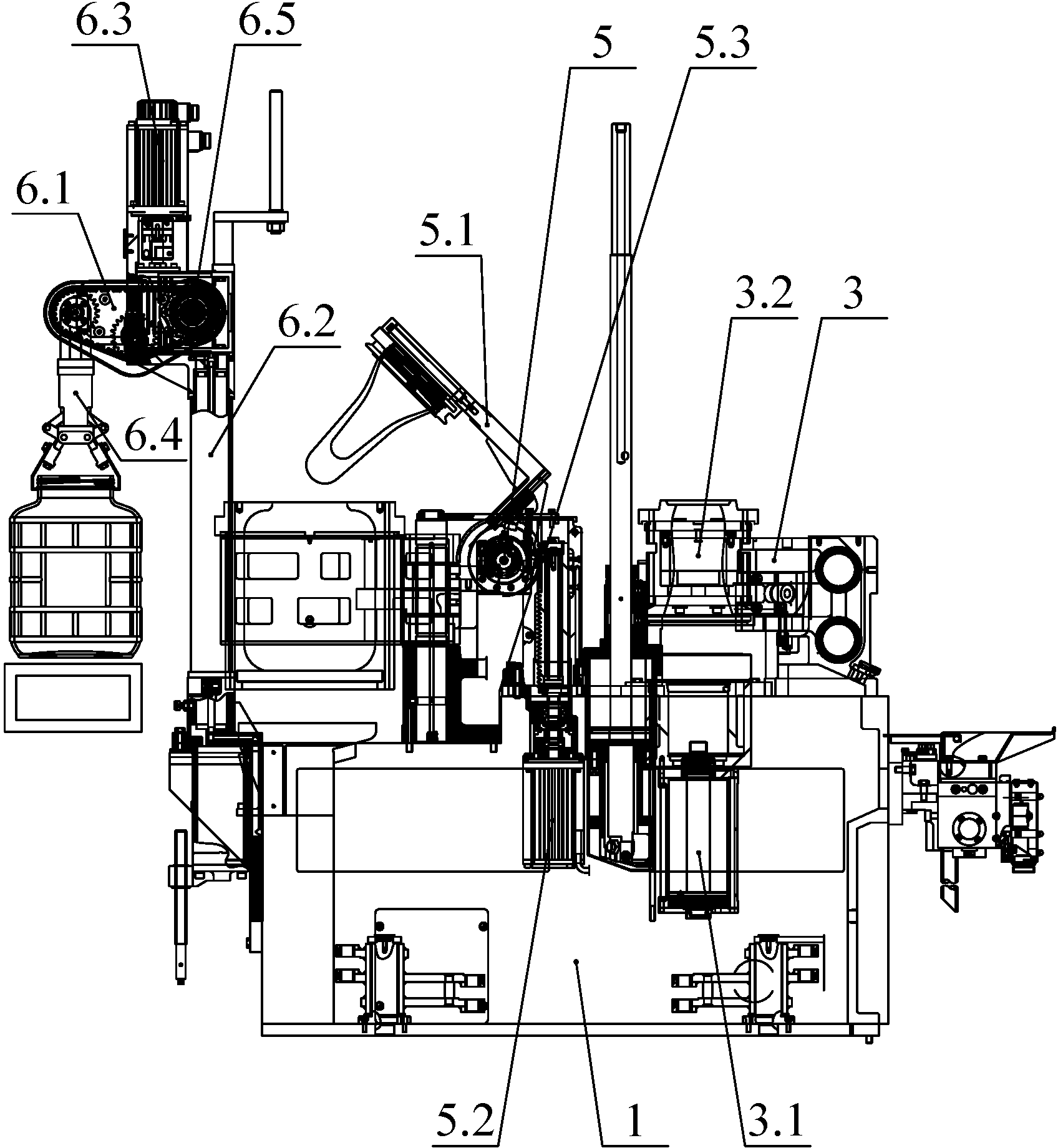

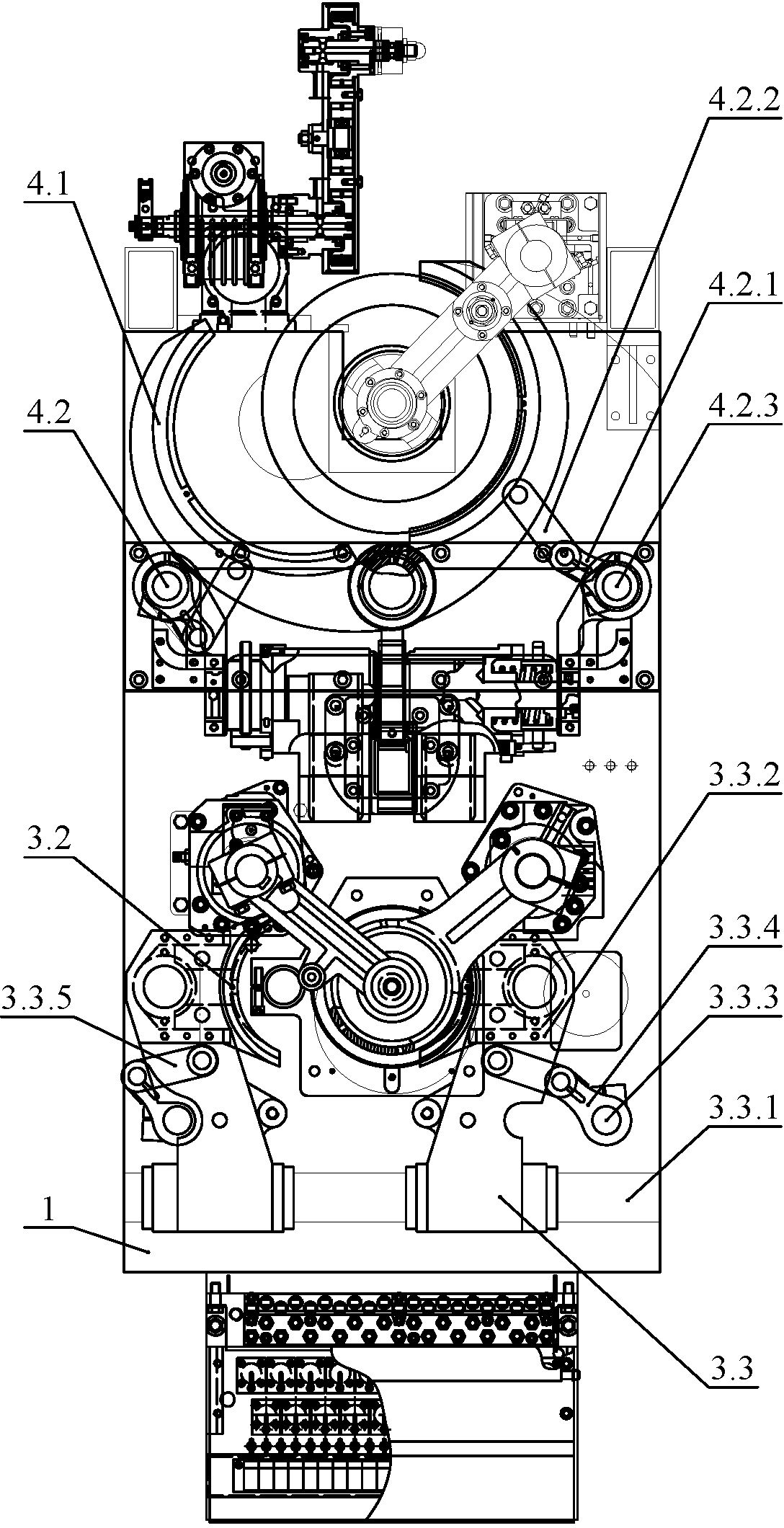

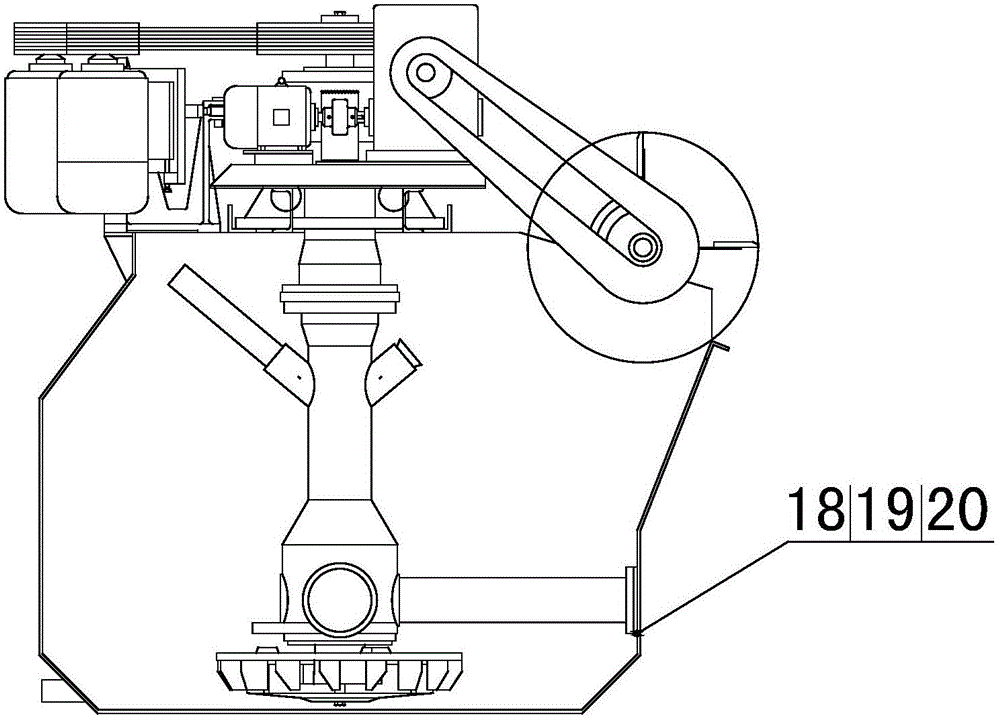

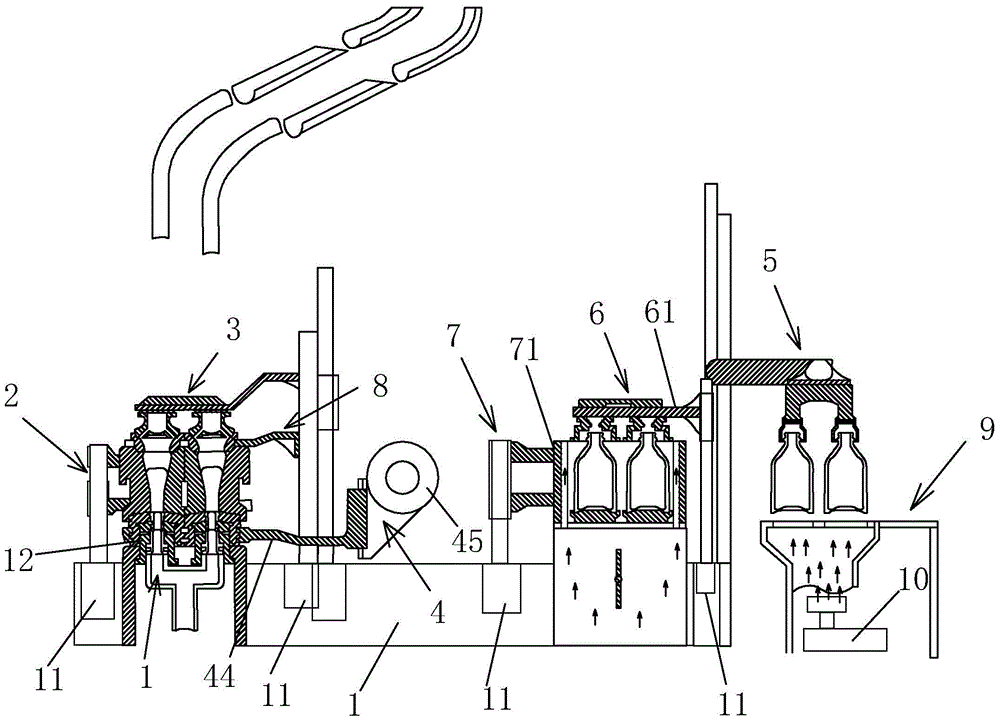

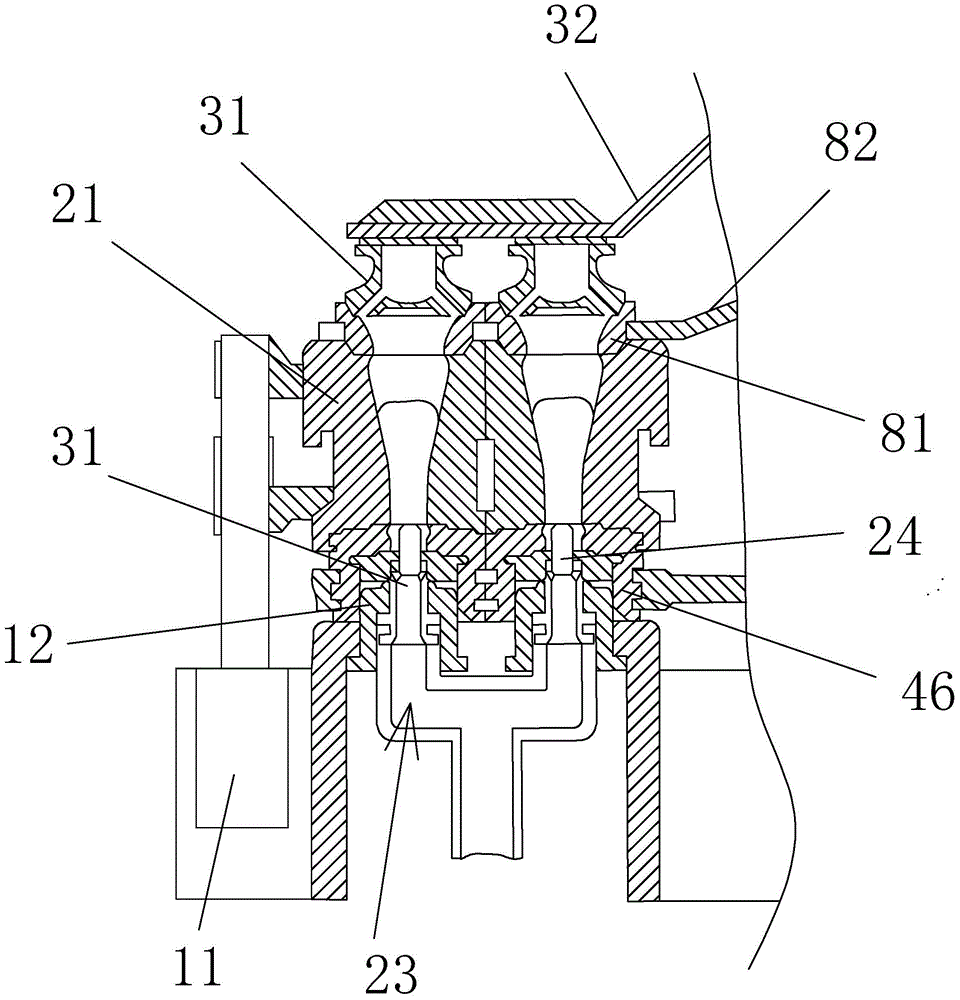

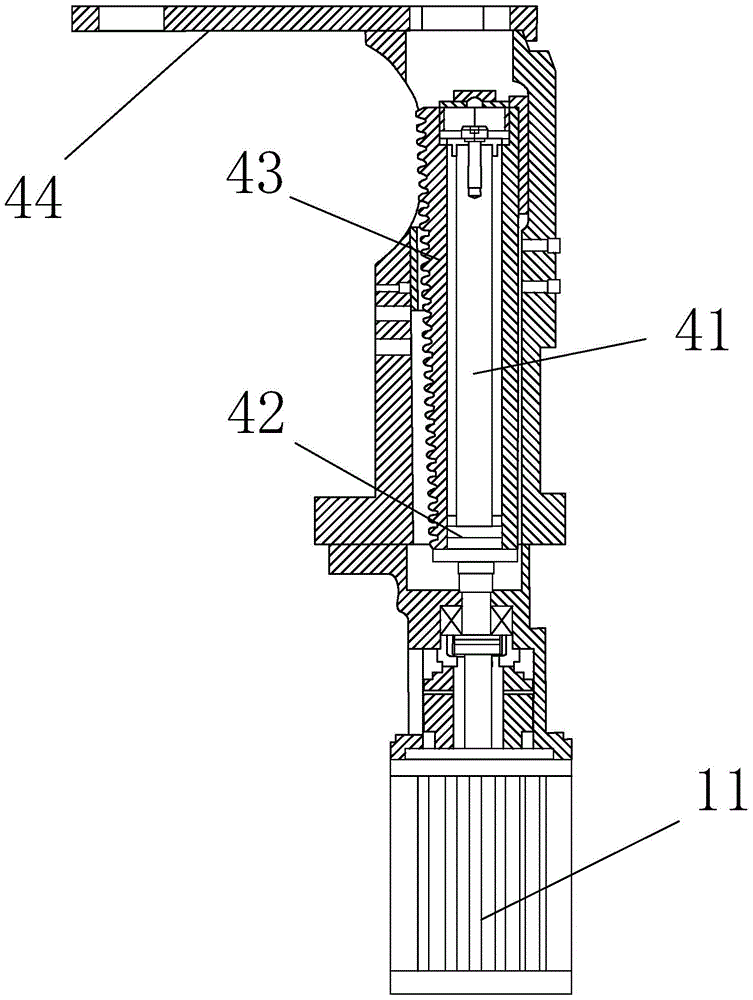

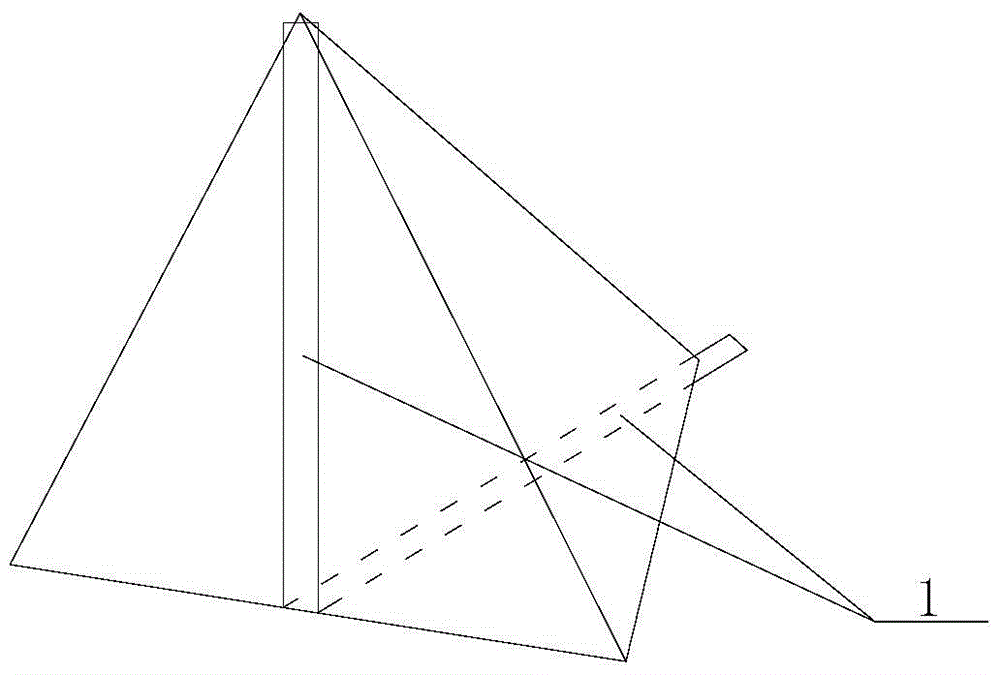

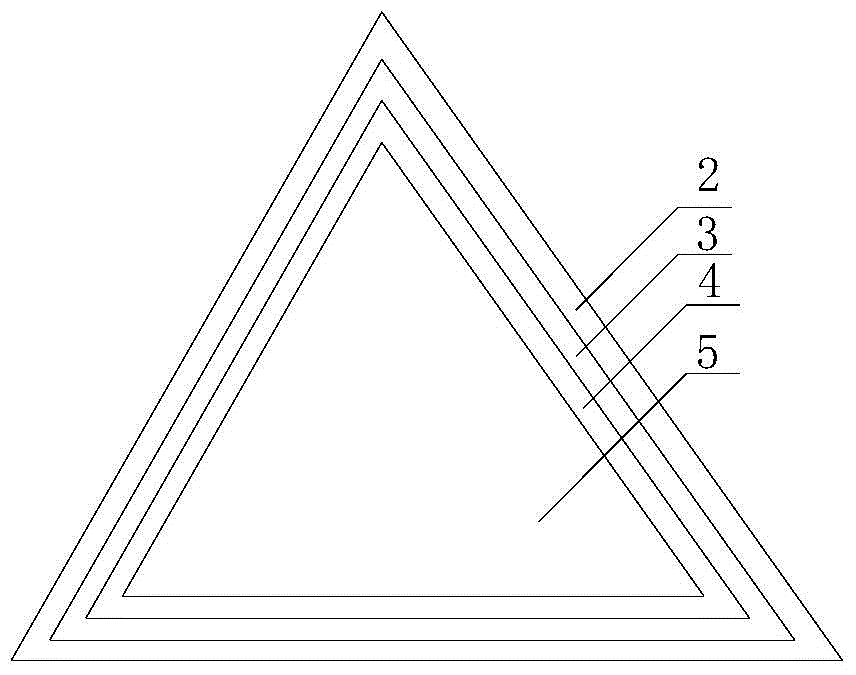

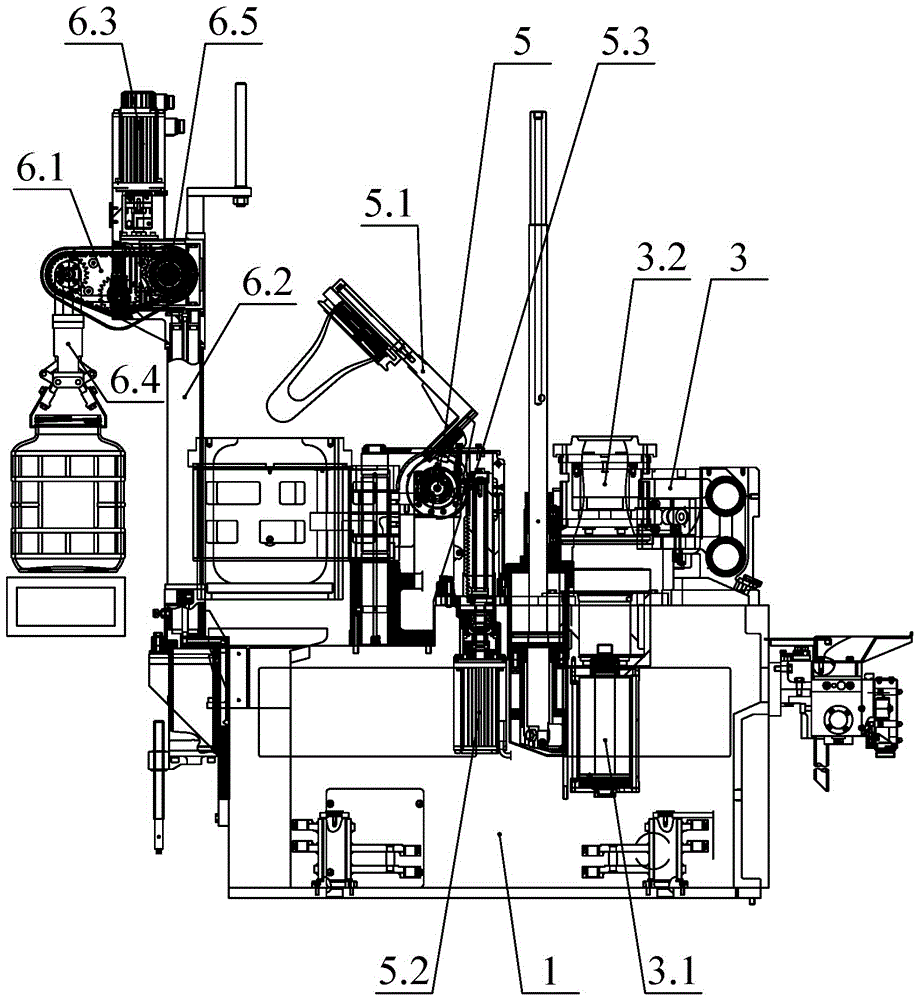

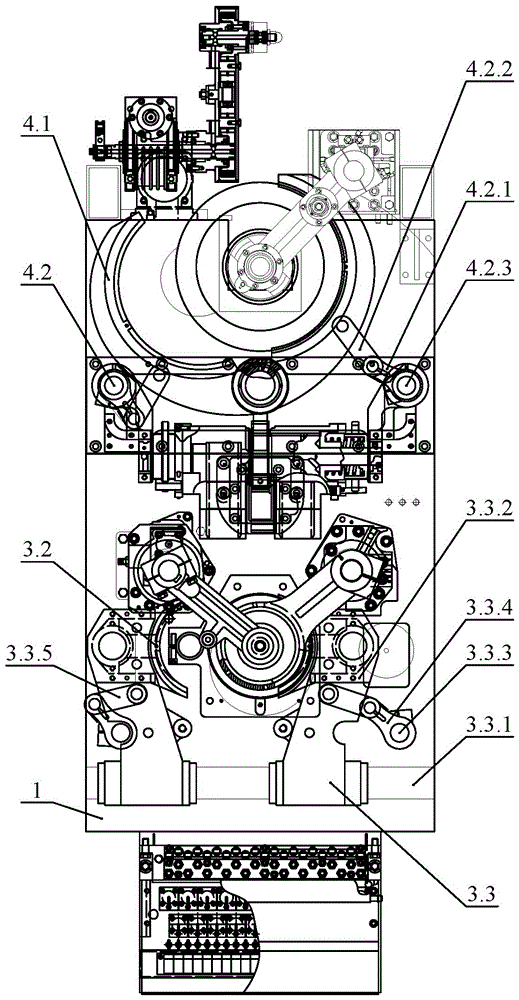

Bottle-making machine and production process for manufacturing extra-large glass bottles

ActiveCN104108856ARealize mechanical automation productionIncrease productionBlowing machine gearingsPress and blow machinesEngineeringBottle

The invention relates to a bottle-making machine and a production process for manufacturing extra-large glass bottles, and belongs to the field of bottle-making machine equipment. The bottle-making machine comprises a rack, and a primary mold forming mechanism, a formed mold forming mechanism and a turnover mechanism which are arranged on the rack, wherein the primary mold forming mechanism comprises a stamping device, a primary mold and a parallel switching mechanism; the stamping device is mounted on the rack; the parallel switching mechanism comprises a horizontal guide shaft mounted on the rack, a clamp arm which sleeves on the horizontal guide shaft, and a first spline shaft, a first rocker arm, a first connecting rod and a first switching cylinder which vertically sleeve at two sides of the rack; one end of the first connecting rod is hinged with the clamp arm while the other end of the first connecting rod is hinged with the first rocker arm; the first rocker arm is connected with the first switching cylinder through the first spline shaft; the primary mold is mounted on the clamp arm. The bottle-making machine has the beneficial effects that the extra-large glass bottles are produced in a manner of automatic mechanized production for replacing manual production, so that the yield of the extra-large glass bottles is increased and the quality of the extra-large glass bottles is improved.

Owner:SHANDONG JIAFENG GLASS MACHINERY

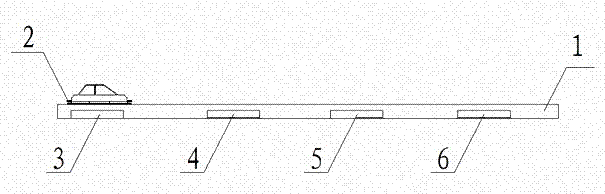

Wire disassembling device of automobile

ActiveCN102897248AEasy to operateReduce labor intensityVehicle dissasembly recoverySolid waste disposalEngineeringPiston rod

The invention discloses a wire disassembling device of an automobile. The device comprises a transportation device, disassembling stations and a tray device, wherein the disassembling stations are arranged along the transportation device, the tray device is arranged on the transportation device, the transportation device is a roller bed provided with rollers, and the roller bed comprises an upper roller bed and a lower roller bed; and the tray device comprises a tray holder, an air cylinder and oriented casters, wherein the oriented casters are arranged on a piston rod of the air cylinder. The technical scheme of the wire disassembling device has the beneficial effects that the wire disassembling device can transport an automobile to be disassembled to the different disassembling stations, the disassembling process is clear, the mechanical automation production of the automobile disassembling operation is realized, manual operation is convenient, the production efficiency is greatly enhanced, the labor intensity of workers and the safety accident rate are reduced, and meanwhile, the wire disassembling device can protect the environment and save resources.

Owner:ANHUI SNELL MACHINERY MFG

Mechanical forming process and equipment of paper pad for packaging box

ActiveCN102303425ARealize mechanical automation productionIncrease production speedContainer making machineryCardboardPunching

The invention relates to a mechanical forming process and equipment of a paper pad for a packaging box. The process comprises the following steps of: firstly punching a paperboard into a semi-finished paperboard according to the designated size and style by a punching machine; and then processing the semi-finished paperboard into the finished paper pad by a forming machine of the paper pad for the packaging box. The forming machine of the paper pad for the packaging box comprises a stepping paperboard conveying mechanism, a longitudinal folding and forming mechanism, a transferring platform, a transverse folding and forming mechanism, a finished product receiving platform, a power part and a control platform. The invention aims to realize mechanical production of the paper pad, greatly improve the production speed, efficiency and the finished product quality, save labor and lower cost; and meanwhile, the obtained paper pad can be widely applied to the light packaging box instead of a foam pad so as to prevent environmental pollution resulting from the use of large number of bubble pads.

Owner:保定市汉德新材料科技有限公司

Rice dumpling and preparation process thereof

The invention discloses a rice dumpling which, from inside to outside, sequentially comprises a dumpling body, an inner plastic film, a dumpling leaf and an outer plastic film. The invention also discloses a preparation process of the rice dumpling, which comprises the following steps of hermetically wrapping the dumpling leaf between the inner plastic film and the outer plastic film, taking the cooked dumpling body, attaching the inner plastic film of the dumpling leaf to the dumpling body, folding, and sealing so as to obtain the rice dumpling. According to the invention, through pre-wrapping the dumpling leaf between food-grade plastic films with an easily-torn tape, the dumpling leaf is kept in a clean state; no poaching process is required to be performed, so that the delicate fragrance of the dumpling leaf is kept more completely, and before the rice dumpling is eaten, through a short-term reheating process, the delicate fragrance of the dumpling leaf is emitted; and when the rice dumpling is eaten, an operation of removing the easily-torn tapes is only required to be performed, thereby not only realizing the easy stripping of the dumpling leaf, but also keeping the delicate fragrance of the dumpling leaf well, so that the dumpling leaf is kept in a clean state, and the rice dumpling is eaten more conveniently; and the whole technological process can achieve automated production.

Owner:ZHEJIANG WUFANGZHAI INDAL

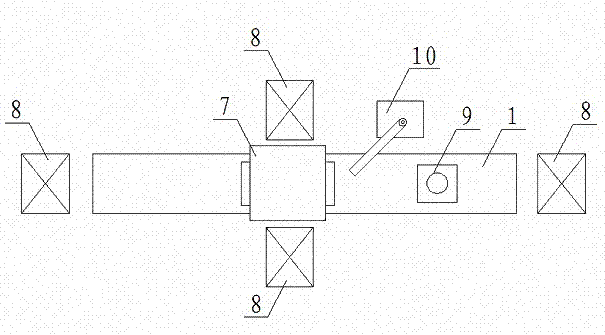

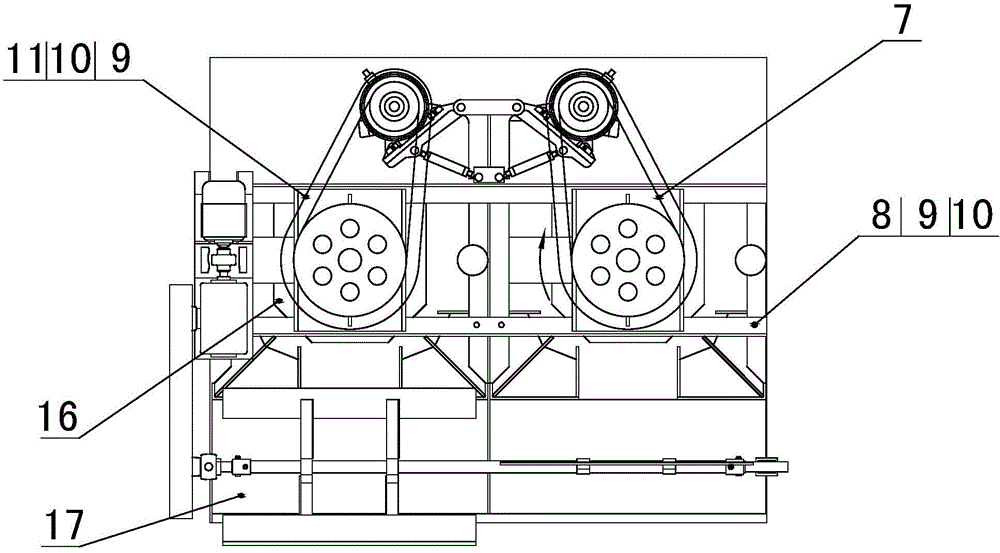

Single-groove inflation stirring type flotation machine

The invention relates to a single-groove inflation stirring type flotation machine and belongs to the technical field of mining machines. The single-groove inflation stirring type flotation machine is composed of a foam scraper blade transmission device (2), a head foam scraper blade (3), a main shaft mechanism (4), a transmission device (6) and groove bodies (17). Air is supplied through an outer air blower, and the air inflating volume of the outer air blower can be adjusted through a valve according to flotation needs; due to the fact that an impeller only performs the function of stirring and does not perform the function of air suction, the rotating speed is low, stirring is not strong, and the argillization phenomenon is not likely to happen when floatation is conducted on fragile objects. The ore pulp surface is stable, a stable foam layer can be easily formed, and thus the grading index can be easily increased; the single-groove inflation stirring type flotation machine is used for separating nonferrous metal, black metal, precious metal and non-metallic minerals, used for rougher flotation, scavenging flotation and fine flotation of chemical materials and used for recycling useful minerals. The single-groove inflation stirring type flotation machine is large in air suction volume, low in power consumption, small in equipment occupied area, convenient to maintain, capable of completely achieving automatic mechanical production, wide in application range and long in service life.

Owner:郭殿君

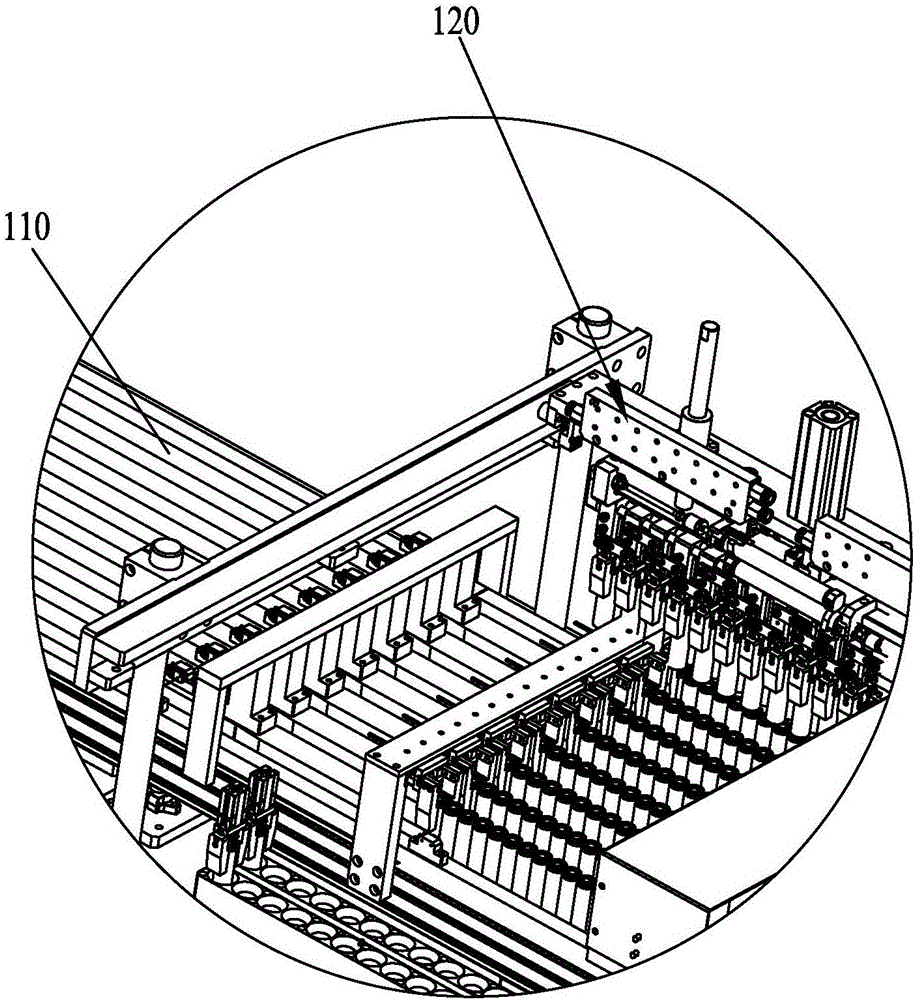

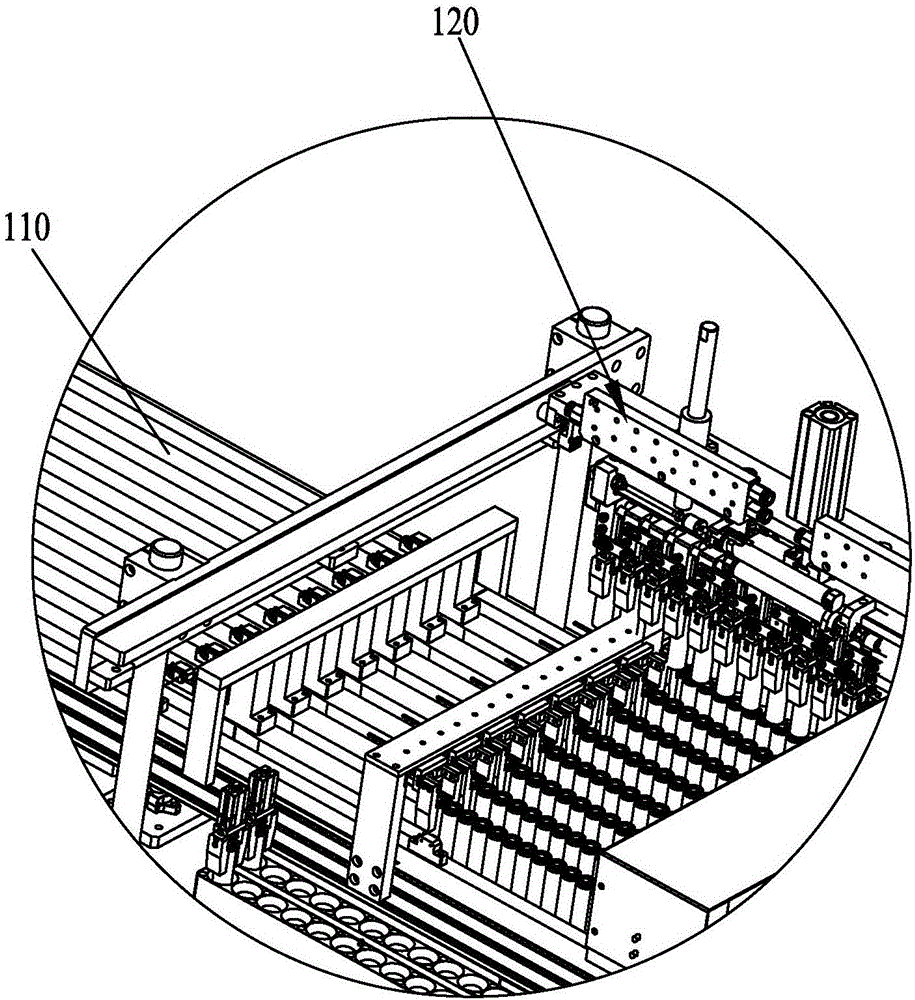

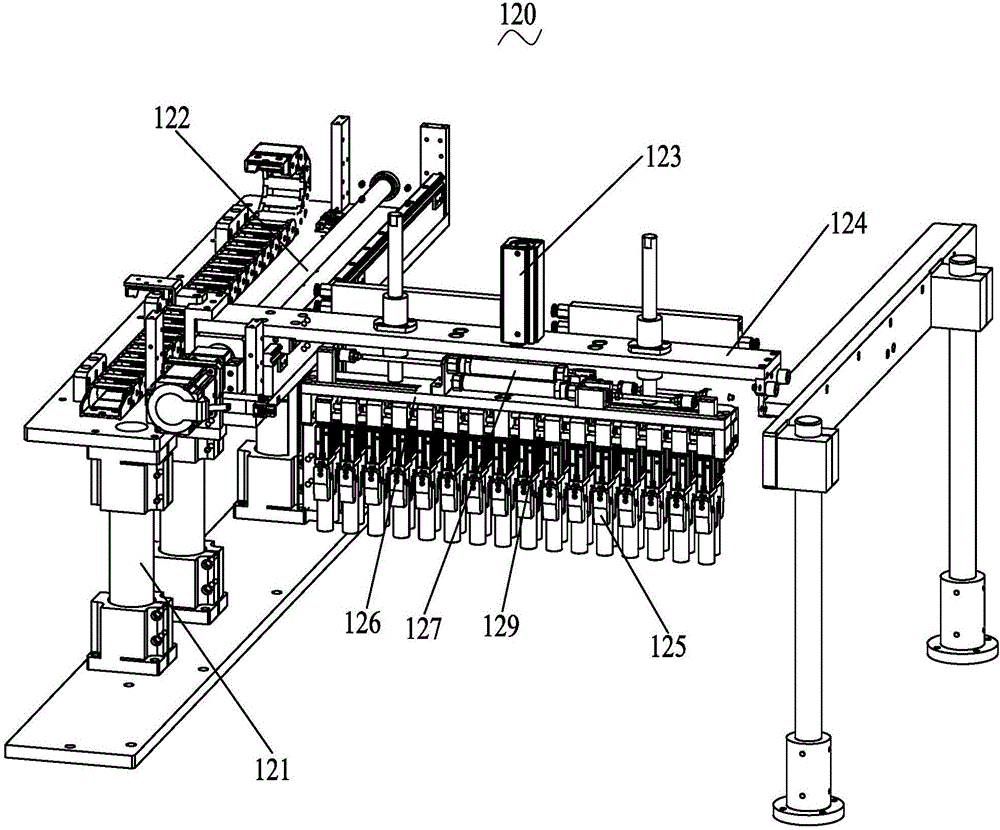

Workbin conveying mechanism and battery sorting collector

InactiveCN106428848ARealize mechanical automation productionIncrease productivityPackaging automatic controlSortingProduction lineIndustrial engineering

The invention discloses a workbin conveying mechanism and a battery sorting collector. The workbin conveying mechanism comprises a workbin conveying production line, multiple workbin lifting devices and multiple workbin positioning devices; the workbin conveying production line is provided with workbin in-place stop cylinders on the workbin lifting devices; a workbin conveying first sensor and a workbin conveying second sensor are spaced on the workbin conveying production line, and are positioned on the workbin lifting devices; and the workbin lifting devices include workbin lifting cylinders and workbin lifting platforms; and the workbin lifting cylinders drive the workbin lifting platforms to perform a lifting motion in the vertical direction. The battery sorting collector optimizes the structures of all mechanisms, realizes automatic mechanical production, and improves the production efficiency.

Owner:HUIZHOU JINYUAN PRECISION AUTOMATION EQUIP

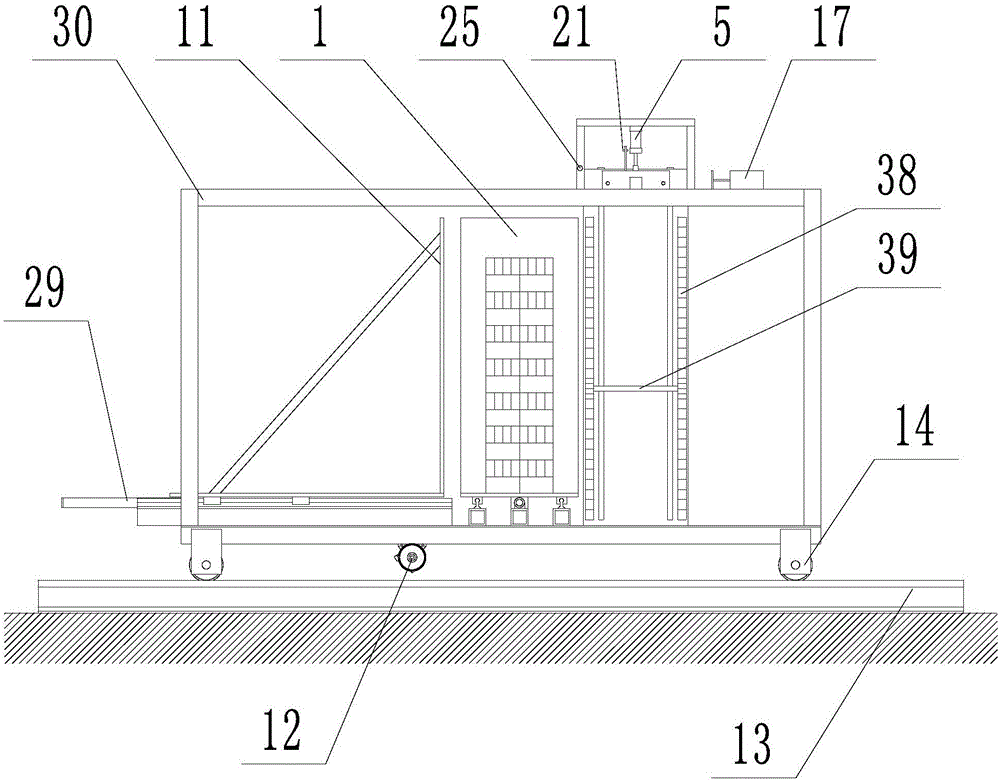

Battery sorting and receiving machine

InactiveCN106391504ARealize mechanical automation productionIncrease productivitySortingEngineeringAutomation

The invention discloses a battery sorting and receiving machine. A battery feeding mechanism is used for conveying batteries at one grade to one battery boxing mechanism; a material box feeding mechanism is used for feeding the multiple sequentially-stacked material boxes to a material box conveying mechanism one by one; the material box conveying mechanism is used for independently conveying the multiple material boxes to the multiple battery boxing mechanisms; the battery boxing mechanisms are used for loading the same-grade batteries in the battery feeding mechanism into the material boxes, and each battery boxing mechanism is used for receiving the batteries at one grade; a box stacking mechanism is used for stacking the material boxes of the battery boxing mechanisms, and the material boxes are full of the batteries; and a finished product discharging and carrying mechanism is used for discharging and transferring the multiple material boxes sequentially stacked at the box stacking mechanism. According to the battery sorting and receiving machine, the structures of all mechanisms are optimized, mechanical automation production is achieved, and the production efficiency is improved.

Owner:HUIZHOU JINYUAN PRECISION AUTOMATION EQUIP

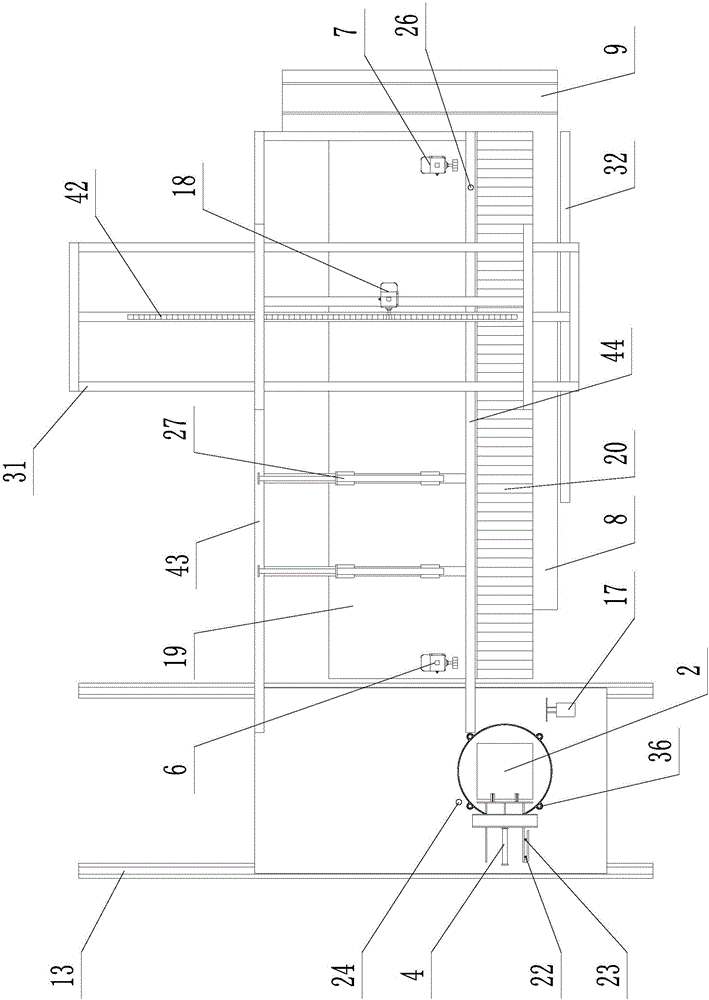

Battery packing mechanism and battery sorting and receiving machine

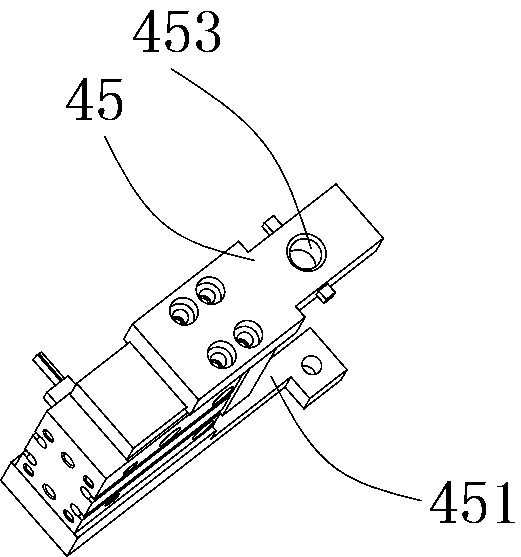

InactiveCN106552777ARealize mechanical automation productionIncrease productivitySortingEngineeringManipulator

The invention discloses a battery packing mechanism and a battery sorting and receiving machine. The battery packing mechanism comprises a battery packing platform, a battery packing manipulator, a left box pushing cylinder, a right box pushing cylinder, a box pushing bar, a battery packing vertical elevation platform and a battery packing vertical elevation driving device. The battery packing manipulator is arranged above the battery packing platform, the left box pushing cylinder and the right box pushing cylinder are respectively positioned at two opposite sides of the battery packing platform, two ends of the box pushing bar are respectively connected with the left box pushing cylinder and the right box pushing cylinder, the box pushing bar is arranged across the battery packing platform, the battery packing vertical elevation platform is connected with the battery packing platform, and the battery packing vertical elevation driving device drives the battery packing vertical elevation platform to move up and down in a vertical direction. The battery sorting and receiving machine formed by optimizing the structures of all above mechanism realizes mechanical automatic production and improves the production efficiency.

Owner:HUIZHOU JINYUAN PRECISION AUTOMATION EQUIP

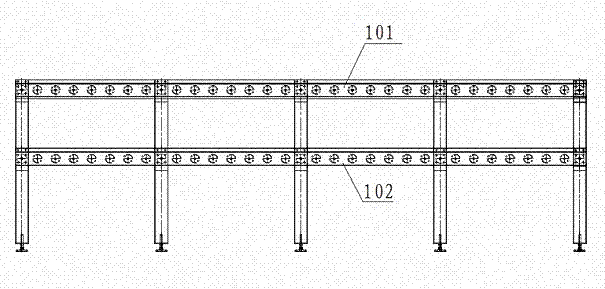

Automatic seamless brick loading machine for tunnel kiln

ActiveCN106276212AImprove work efficiencyReduce operating costsStacking articlesDe-stacking articlesTunnel kilnBrick

The invention relates to the field of building material loading equipment, in particular to an automatic seamless brick loading machine for a tunnel kiln. The automatic seamless brick loading machine comprises a brick loading system, a brick unloading system and a traveling system. The brick loading system comprises a brick loading rack, a brick feeding mechanism, a brick loading mechanism and a brick pushing mechanism, wherein the brick feeding mechanism, the brick loading mechanism and the brick pushing mechanism are arranged on the brick loading rack. The brick unloading system comprises a carrying cart mechanism and a brick unloading mechanism, wherein the carrying cart mechanism comprises a lifting table, a lifting table support and a lifting table driving device driving the lifting table to rise and fall. The traveling system comprises a brick loading rack traveling mechanism and a traveling frame traveling mechanism. According to the automatic seamless brick loading machine, through cooperation of hydraulic automation, mechanical automation and electrical automation, piled bricks stacked on a kiln car are automatically transferred into a carriage of a loading transport cart, traditional manual brick loading is replaced, and mechanical and automatic production is achieved; and not only is work efficiency of cart loading of the piled bricks greatly improved, but also manpower is greatly saved, and the operating cost of an enterprise can be greatly lowered.

Owner:刘作礼

Cell cleaning equipment

ActiveCN104916862ARealize mechanical automation productionFinal product manufactureSecondary cells manufactureWater circulationManipulator

The present invention relates to cell cleaning equipment, which is used for cleaning cells and comprises: a bubbling-liquid circulation tank, a feeding manipulator, a pickling circulation tank, a caustic washing circulation tank, a clean water circulation tank, an unloading manipulator, a constant temperature oven, a transfer manipulator and a discharging line. Delivery manipulators are provided between the pickling circulation tank, the caustic washing circulation tank and the clean water circulation tank; and a turntable, a reversing manipulator, and a cleaning apparatus are provided in each of the pickling circulation tank, the caustic washing circulation tank and the clean water circulation tank. The constant temperature oven is provided with a rotating cell storage chain; the unloading manipulator transfers cells in the clear water circulation tank to the cell storage chain; and the transfer manipulator transfers the cells on the cell storage chain to the discharging line. The cell cleaning equipment completes feeding, cleaning, drying and unloading of cells, thereby realizing mechanical automated production of cells.

Owner:EVE ENERGY CO LTD

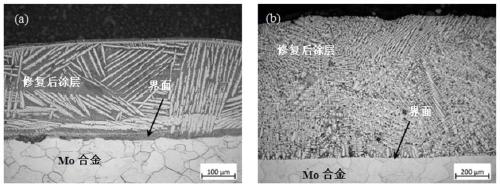

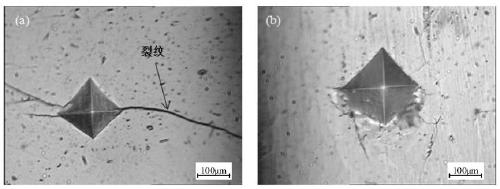

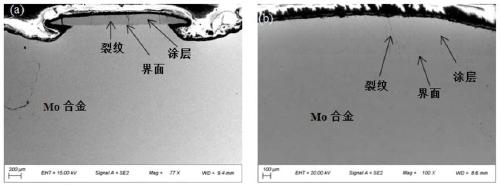

Method for repairing silicide coating on surface of Mo alloy sheet

InactiveCN111172530AImprove economyImprove the effect of practiceMetallic material coating processesAl powderOxidation resistant

The invention relates to a method for repairing a silicide coating on the surface of a Mo alloy sheet. The method comprises the following steps of first, polishing the surface of a peeling-off part ofthe silicide coating on the surface of the Mo alloy sheet, preparing from the following components in percentage by mass: 2%-5% of Nb powder, 3%-5% of Al powder, 1%-2% of Cr powder, 0.5%-1% of W powder, 0.2%-0.5% of B powder, 0.1%-0.2% of Ti powder, and the balance of MoSi2 powder, and performing ball milling to obtain mixed alloy powder mainly based on MoSi2, then using ethanol as a binder to bepre-arranged and attached to the coating peeling-off part, drying to obtain a pre-arranged coating, and finally performing TIG arc cladding on the pre-arranged coating by using TIG arc welding, thereby obtaining an arc cladding repair coating on the surface of the Mo alloy sheet. The method can improve the interface bonding strength and high temperature oxidation resistance of the repaired coating.

Owner:JIANGSU UNIV OF TECH

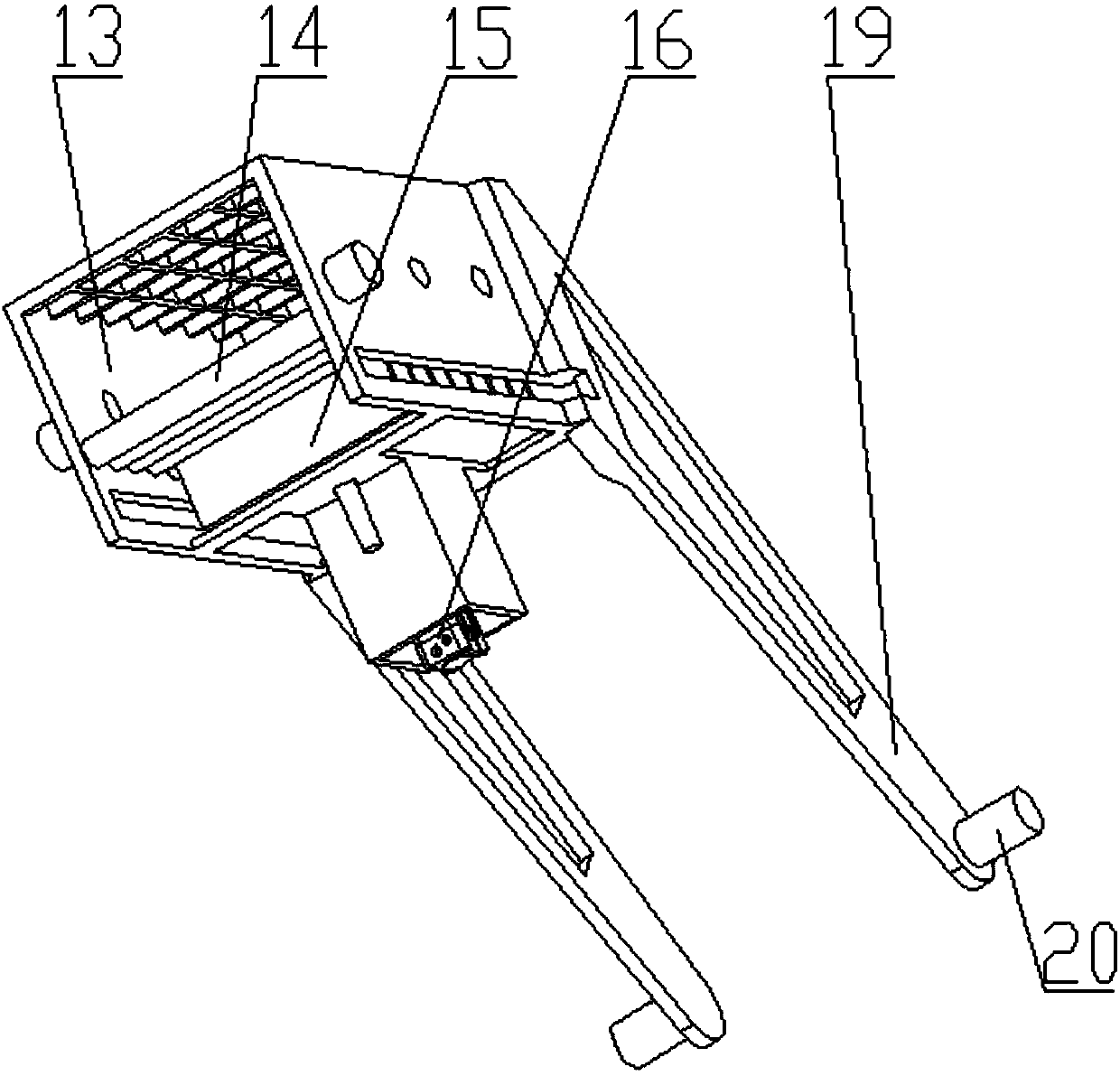

Overturning and wire feeding device and method for waste lead-acid batteries

ActiveCN107706479ASolve on-lineSolve flipWaste accumulators reclaimingBattery recyclingEngineeringSpent acid

The invention discloses an overturning and wire feeding device for waste lead-acid batteries, and is used for carrying out overturning and wire feeding of the waste lead-acid batteries after being cut. The device is characterized by mainly comprising an overturning rack, a battery clamping mechanism, an overturning power mechanism and a pushing mechanism; the battery clamping mechanism, the overturning power mechanism and the pushing mechanism are arranged below the overturning rack, the battery clamping mechanism is connected with the overturning power mechanism, and an overturning action isrealized under the effect of the overturning power mechanism; the battery clamping mechanism is positioned below the pushing mechanism when being in an initial state, and when the battery clamping mechanism is overturned to a horizontal height corresponding to the pushing mechanism through the overturning power mechanism, the pushing mechanism acts to push out the waste lead-acid batteries clampedin the battery clamping mechanism. The wire feeding and overturning problems of a battery jar are effectively solved, mechanical automation production is realized, and the damage of a spent acid solution in the battery jar on the environment and the human bodies of workers is avoided.

Owner:GUIZHOU CENXIANG RESOURCE TECH CO LTD +2

Handbag automatic stringing equipment

ActiveCN106584919BRealize mechanical automation productionIncrease productivityBag making operationsPaper-makingEngineeringMechanical engineering

The invention provides automatic rope threading equipment for carry bags. The equipment comprises a rack; a feeding mechanism, box opening mechanisms, perforating mechanisms, rope conveying mechanisms and rope threading mechanisms are arranged on the rack; the feeding mechanism penetrates through the box opening mechanisms; each perforating mechanism comprises an upper-layer perforating assembly and a lower-layer perforating assembly which are arranged vertically symmetrically; each rope threading mechanism comprises an upper-layer rope threading assembly and a lower-layer rope threading assembly which are arranged vertically symmetrically; each rope conveying mechanism comprises an upper-layer rope conveying assembly and a lower-layer rope conveying assembly which are arranged vertically symmetrically; the upper-layer rope conveying assemblies correspond to the upper-layer rope threading assemblies; and the lower-layer rope conveying assemblies correspond to the lower-layer rope threading assemblies. With the equipment, multiple procedures such as feeding, box opening, perforating, rope conveying, rope threading and the like are integrated, mechanical and automatic production is realized, the production time is greatly shortened, the production efficiency is improved, the labor cost is reduced, meanwhile, bad products caused by human factors are avoided, the uniformity of products is guaranteed, and the overall yield of the products is increased.

Owner:武汉世豪同创自动化设备有限公司

Box stacking mechanism and battery sorting receiver

InactiveCN106395301AOptimize structureRealize mechanical automation productionConveyorsControl devices for conveyorsEngineeringAssembly line

The invention discloses a box stacking mechanism and a battery sorting receiver. The box stacking mechanism comprises a stacked box lift driving device, a stacked box lifting platform, a stacked box assembly line and a stacked box separating device. The stacked box lift driving device is used for driving the stacked box lifting platform to do a lift motion along the vertical direction; the stacked box separating device is positioned above the stacked box lifting platform; and the stacked box assembly line is engaged with a battery boxing vertical lifting platform. By optimizing the structure of each mechanism, the batter sorting receiver can realize mechanical automatic production and improve the production efficiency.

Owner:HUIZHOU JINYUAN PRECISION AUTOMATION EQUIP

All-electric bottle making machine

ActiveCN105753298AAccurate timingFast actionBlowing machine gearingsBlow headsMicrocomputerMicrocontroller

The invention discloses an all-electric bottle making machine.The all-electric bottle making machine comprises a frame, an initial mould forming mechanism, an aeration mechanism, a turnover mechanism, a clamp movement mechanism and a forming mould forming mechanism, the initial mould forming mechanism, the aeration mechanism, the turnover mechanism and the clamp movement mechanism are mounted on the frame, and the forming mould forming mechanism is provided with a positive blowing mechanism.The turnover mechanism is positioned between the initial mould forming mechanism and the forming mould forming mechanism.A funnel mechanism comprises a screw rod, a nut, a cam shaft, a funnel support, a funnel arm and a funnel.Each mechanism is connected with a servo motor which is connected with a single-chip microcomputer through a signal line, the servo motor is in transmission connection with one end of the screw rod, the nut is in threaded fit with the screw rod, the funnel is mounted on the funnel arm which is fixed to the funnel support, the funnel support is connected with the cam shaft, and the nut drives the cam shaft so as to drive the funnel arm to move.The all-electric bottle making machine has the advantage that the problem of high production cost caused by high noise, failure in energy saving, poor air pressure stability, mechanism action instability, small product range and inconvenience in maintenance of pneumatic bottle making machines is solved.

Owner:HANGZHOU ZHENHUA COSMETIC GLASS

Two-way automatic feeding device

ActiveCN107973115ARealize mechanical automation productionGuaranteed automatic loadingConveyorsConveyor partsEngineeringElectrical and Electronics engineering

The invention discloses a two-way automatic feeding device comprising a workbench; a feed fetching mechanism is arranged on the workbench; two groups of supplying mechanisms are symmetrically locatedat two sides of the feed fetching mechanism; the supplying mechanisms comprise air cylinder vertical plates arranged vertical to the workbench, signaling switches and inclination plates, and a gap islocated between the bottom surface of the inclination plates and the workbench; passages are arranged on the inclination plates; a catching groove is arranged under the tail ends of the passages; andthe other ends of the air cylinder vertical plates are provided with a driving mechanism. By adopting the structure, not only can the automatic feeding be ensured, but also a two-way simultaneous supply is achieved; when the next workshop section is far away, and the feeding travel can be increased through a rodless air cylinder; through the mechanical way, the feeding speed is accelerated, and the efficiency is increased; and the factory is liberated from heavy manual labor, manpower cost is reduced; and mechanical automation production of factories is achieved, and safety hazards of manual feeding is directly avoided.

Owner:宁波优耐特模具有限公司

A two-way automatic feeding device

ActiveCN107973115BRealize mechanical automation productionGuaranteed automatic loadingConveyorsConveyor partsReclaimerWorkbench

The invention discloses a two-way automatic feeding device comprising a workbench; a feed fetching mechanism is arranged on the workbench; two groups of supplying mechanisms are symmetrically locatedat two sides of the feed fetching mechanism; the supplying mechanisms comprise air cylinder vertical plates arranged vertical to the workbench, signaling switches and inclination plates, and a gap islocated between the bottom surface of the inclination plates and the workbench; passages are arranged on the inclination plates; a catching groove is arranged under the tail ends of the passages; andthe other ends of the air cylinder vertical plates are provided with a driving mechanism. By adopting the structure, not only can the automatic feeding be ensured, but also a two-way simultaneous supply is achieved; when the next workshop section is far away, and the feeding travel can be increased through a rodless air cylinder; through the mechanical way, the feeding speed is accelerated, and the efficiency is increased; and the factory is liberated from heavy manual labor, manpower cost is reduced; and mechanical automation production of factories is achieved, and safety hazards of manual feeding is directly avoided.

Owner:宁波优耐特模具有限公司

A kind of Zongzi and its production process

The invention discloses a rice dumpling which, from inside to outside, sequentially comprises a dumpling body, an inner plastic film, a dumpling leaf and an outer plastic film. The invention also discloses a preparation process of the rice dumpling, which comprises the following steps of hermetically wrapping the dumpling leaf between the inner plastic film and the outer plastic film, taking the cooked dumpling body, attaching the inner plastic film of the dumpling leaf to the dumpling body, folding, and sealing so as to obtain the rice dumpling. According to the invention, through pre-wrapping the dumpling leaf between food-grade plastic films with an easily-torn tape, the dumpling leaf is kept in a clean state; no poaching process is required to be performed, so that the delicate fragrance of the dumpling leaf is kept more completely, and before the rice dumpling is eaten, through a short-term reheating process, the delicate fragrance of the dumpling leaf is emitted; and when the rice dumpling is eaten, an operation of removing the easily-torn tapes is only required to be performed, thereby not only realizing the easy stripping of the dumpling leaf, but also keeping the delicate fragrance of the dumpling leaf well, so that the dumpling leaf is kept in a clean state, and the rice dumpling is eaten more conveniently; and the whole technological process can achieve automated production.

Owner:ZHEJIANG WUFANGZHAI INDAL

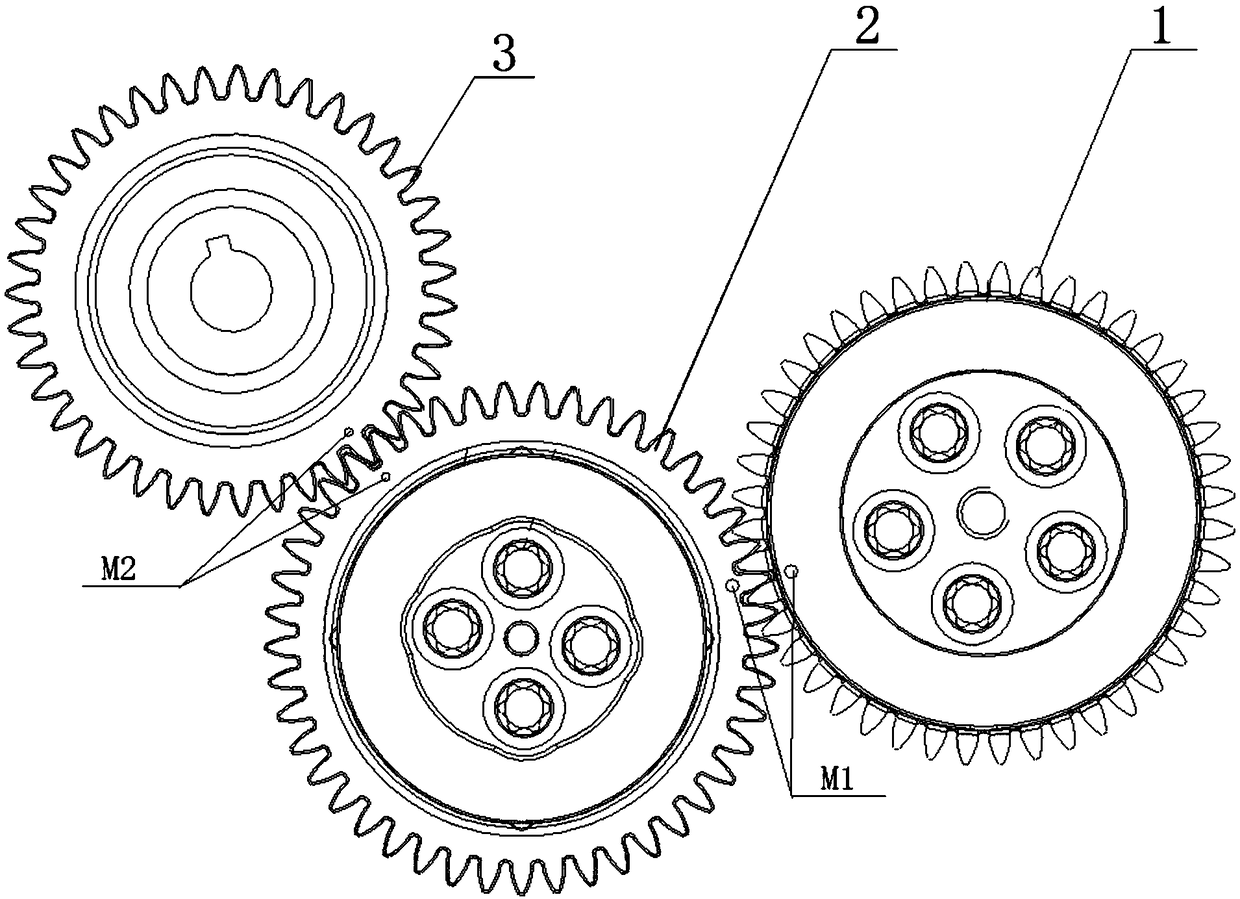

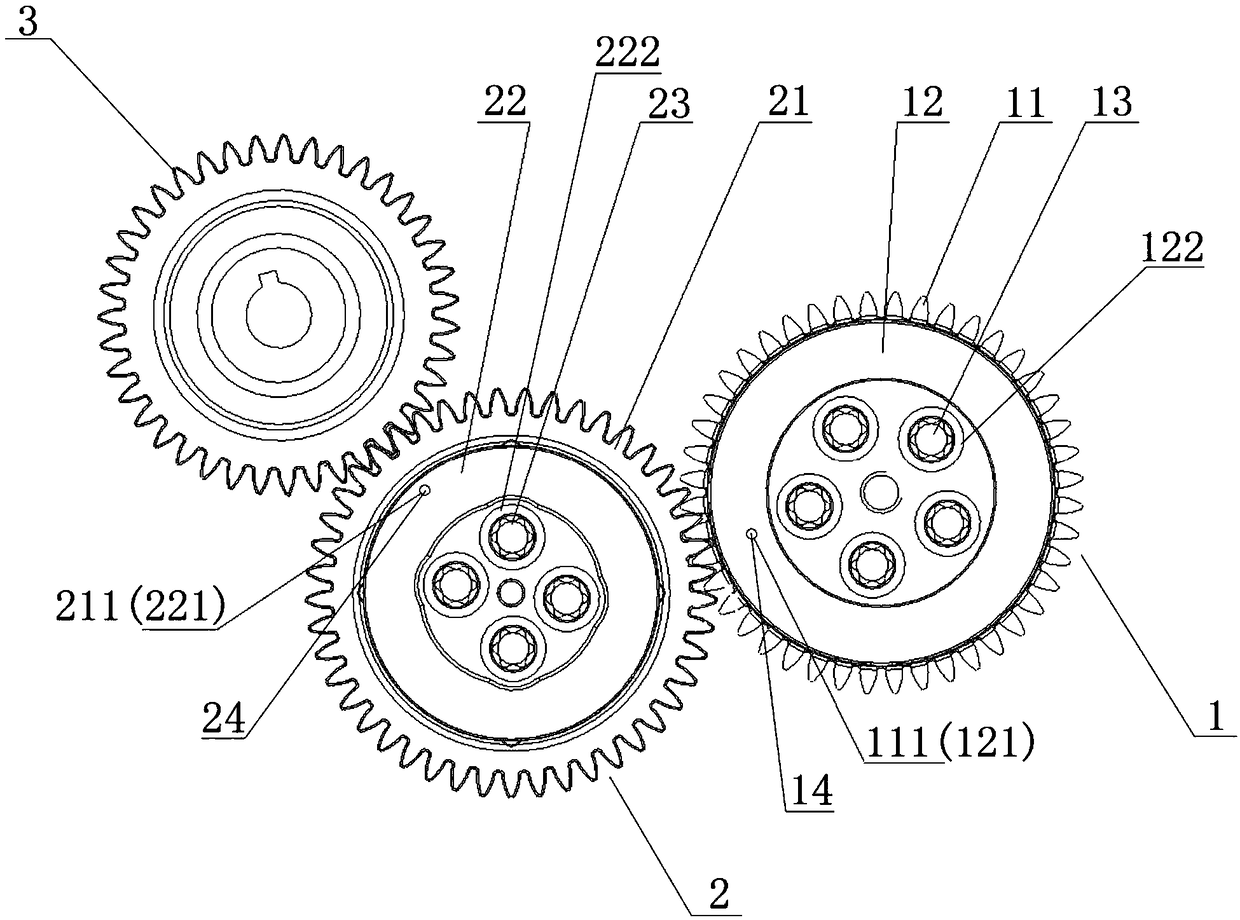

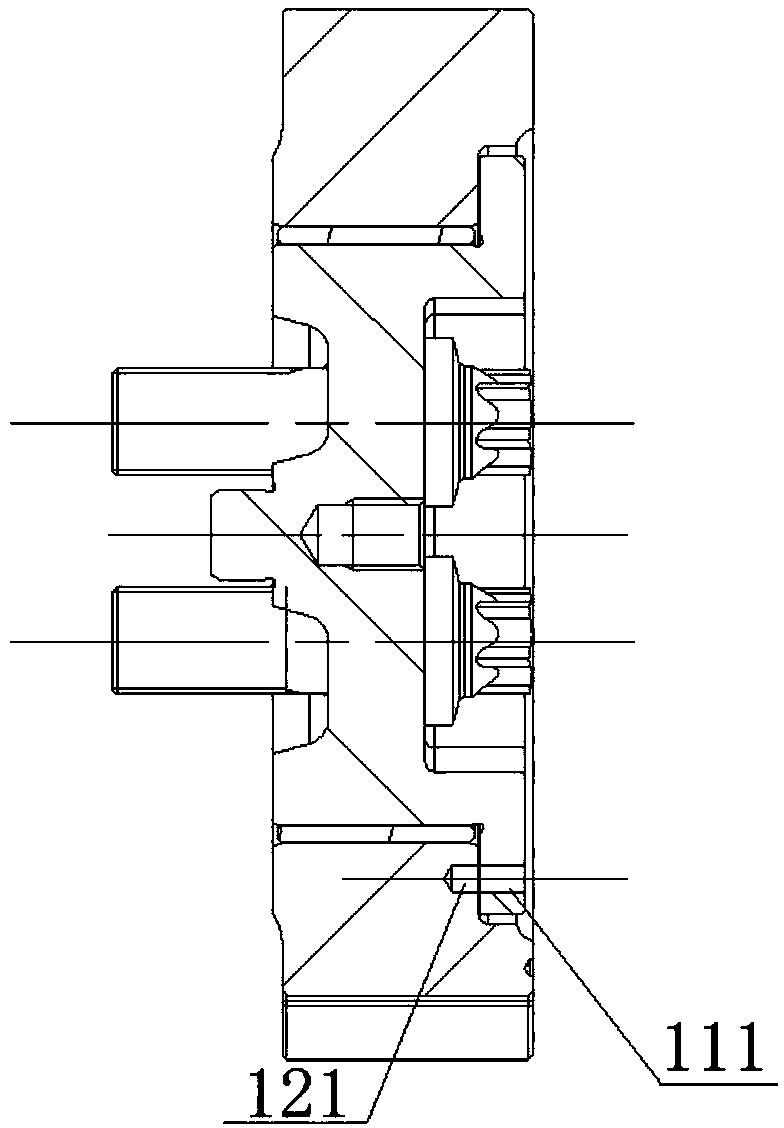

Idle gear part of engine

PendingCN109236954AReduce labor intensityRealize mechanical automation productionToothed gearingsPositioning technologyTiming mark

The invention discloses an idle gear part of an engine. The part is meshed with an oil pump gear, and the oil pump gear is fixed on an engine body. The idle gear part of the engine includes an intermediate inert gear and an oil pump inert gear. The intermediate inert gear is composed of a first inert gear, a first inert gear shaft and at least one first installation bolt, and the intermediate inert gear is fixed on the engine body; the oil pump inert gear is composed of a second inert gear, a second inert gear shaft and at least one second installation bolt. One side of the oil pump inert gearis meshed with the intermediate inert gear, the other side is meshed with the oil pump gear, and the oil pump gear is fixed on the engine body. The first inert gear is provided with a first positioning technology hole, the first inert gear shaft is provided with a second positioning technology hole, and the first positioning technology hole and the second positioning technology hole are same in diameter and coincides. Therefore, the idle gear part of the engine does not need to make a timing mark on the inert gear, the assembly is simple, and the production efficiency is high.

Owner:GUANGXI YUCHAI MASCH CO LTD

Double-way material sorting device

ActiveCN108147097ARealize mechanical automation productionIncrease the feeding speedControl devices for conveyorsLoading/unloadingPass rateEngineering

The invention discloses a material sorting device. The material sorting device comprises a material sorting table; a material storing device with a material guiding opening is arranged on the materialsorting table; a material sorting device body supported by a support is correspondingly arranged below the material guiding opening; a gas source treating device is arranged at the rear of the material sorting device body; and the material sorting device body comprises structures of a material pressing mechanism, a material conveying plate, an infrared counter and the like. Through cooperation among the structures and through monitoring of a monitoring device, the effect that unqualified products are automatically sorted is achieved, meanwhile, the reject rate can be accurately calculated, and thus the equipment quality is further improved; and workpieces are sorted through the mechanical means, the material sorting speed is increased, the material sorting efficiency is improved, workersof factories are liberated from heavy manual labor, the manpower cost is reduced, factory machinery automatic production is achieved, the error of manual sorting is directly avoided, and the product pass rate is directly and effectively increased.

Owner:宁波优耐特模具有限公司

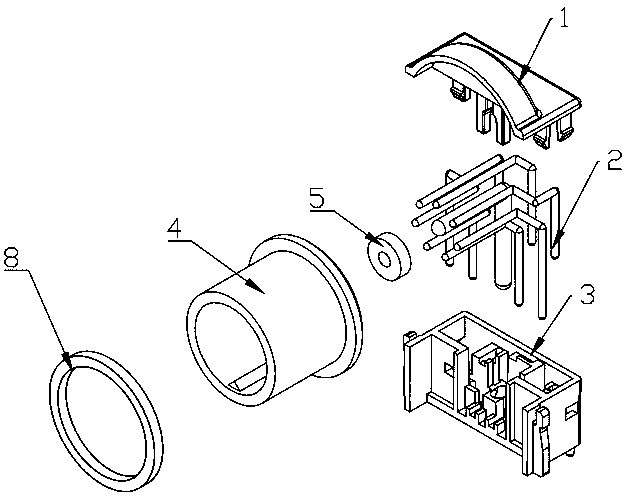

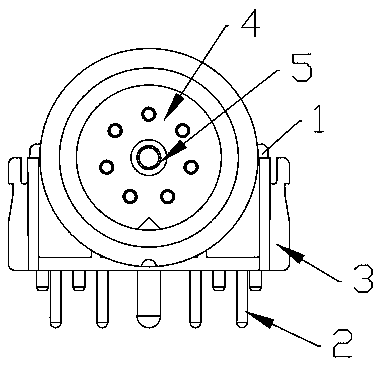

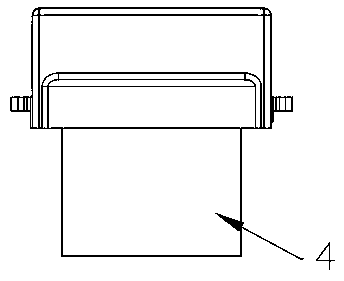

Wire connector and its assembly method

ActiveCN106252913BReduce volumeStable terminal positionElectrically conductive connectionsContact member assembly/disassemblyModularityEngineering

The invention relates to a connector and an assembly method thereof. The utility model aims to solve the problems of easy damage and short service life of the connector in the prior art. The invention includes a terminal and a terminal box. The terminal is installed in the terminal box. There is a space angle of 30-150° between the outlet and the inlet. The terminal includes a certain number of conductive rods, and there is at least one fold on the conductive rod Bend to meet the formation of the space angle, the junction box includes a sheath at the outlet end and a limit card mold at the outlet end. The limit card mold is provided with a partition unit for isolating each conductive rod and a guide mounting hole for positioning each conductive rod. The beneficial effects are: the inlet and outlet of the modularly assembled junction box form a fixed angle, and the various lines do not interfere with each other; the overall structure is well sealed; the deformation of the main board during use is further prevented; The number of bending times of the rod can form a variety of inlet and outlet forms; solder joint processing is avoided, and working time and labor intensity are saved.

Owner:XINXIANG GUANGMING ELECTRIC APPLIANCE CO LTD

Distribution device

ActiveCN108144871BRealize mechanical automation productionAchieve automatic sortingSortingEngineeringMaterial storage

Owner:宁波优耐特模具有限公司

Material clamping mechanism of automatic charging device

ActiveCN108163523ARealize mechanical automation productionGuaranteed automatic loadingLiquid surface applicatorsCleaning using toolsRisk strokeAngle alpha

The invention discloses a material clamping mechanism of an automatic charging device. The material clamping mechanism comprises a workbench; a material taking mechanism, an air blowing mechanism, anda feeding mechanism which is arranged on one side of the material taking mechanism are arranged on the workbench; a mechanical arm driven by a driving device is arranged at the front end of a rodlessair cylinder; a protective device is hinged to the mechanical arm; the protective device comprises block pieces symmetrically arranged on the two sides of the mechanical arm; each block piece is provided with two arc-shaped structures; the two block pieces are arranged reversely; and an included angle alpha is formed between the two block pieces. With the adoption of the structure, automatic charging can be ensured, and the charging can not be affected in the charging process when a workpiece falls off; when a working section is far, the feeding stroke can be increased through the rodless aircylinder; and with the adoption of the mechanical mode, the charging is accelerated, the efficiency is improved, a factory is liberated from heavy manual labor, the manpower cost is lowered, mechanical automation production of the factory is realized and potential safety hazards in manual charging are avoided directly.

Owner:宁波优耐特模具有限公司

A kind of battery cleaning equipment

ActiveCN104916862BRealize mechanical automation productionFinal product manufactureSecondary cells manufactureEngineeringTransfer mechanism

The invention relates to a cell cleaning equipment, which is used to clean the cell, including a liquid foam circulating water tank, a feeding manipulator, a pickling circulating water tank, an alkali washing circulating water tank, a clear water circulating water tank, a material unloading manipulator, a constant temperature oven, a transfer Manipulator and discharge line. There is a transfer manipulator between the pickling circulating water tank, alkali washing circulating water tank and clean water circulating water tank. The pickling circulating water tank, alkali washing circulating water tank and clean water circulating water tank are equipped with a turntable, turning manipulator and cleaning device; the constant temperature oven is equipped with There is a rotating cell storage chain, the unloading manipulator transfers the cells in the clear water circulating water tank to the cell storage chain, and the transfer manipulator transfers the cells on the cell storage chain to the discharge line. The cell cleaning equipment completes the loading, cleaning, drying and unloading operations of the cells, and realizes the mechanical automation production of the cells.

Owner:EVE ENERGY CO LTD

A two-way distributing device

ActiveCN108147097BRealize mechanical automation productionIncrease the feeding speedControl devices for conveyorsLoading/unloadingPass rateWaste product

The invention discloses a material sorting device. The material sorting device comprises a material sorting table; a material storing device with a material guiding opening is arranged on the materialsorting table; a material sorting device body supported by a support is correspondingly arranged below the material guiding opening; a gas source treating device is arranged at the rear of the material sorting device body; and the material sorting device body comprises structures of a material pressing mechanism, a material conveying plate, an infrared counter and the like. Through cooperation among the structures and through monitoring of a monitoring device, the effect that unqualified products are automatically sorted is achieved, meanwhile, the reject rate can be accurately calculated, and thus the equipment quality is further improved; and workpieces are sorted through the mechanical means, the material sorting speed is increased, the material sorting efficiency is improved, workersof factories are liberated from heavy manual labor, the manpower cost is reduced, factory machinery automatic production is achieved, the error of manual sorting is directly avoided, and the product pass rate is directly and effectively increased.

Owner:宁波优耐特模具有限公司

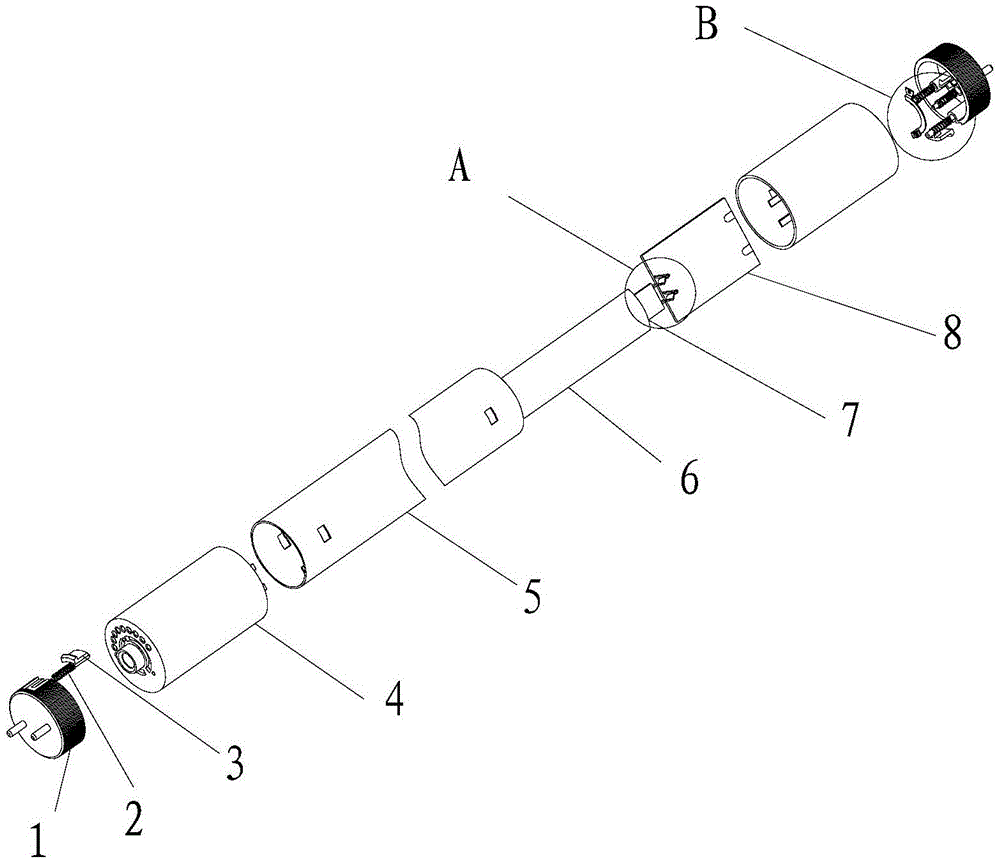

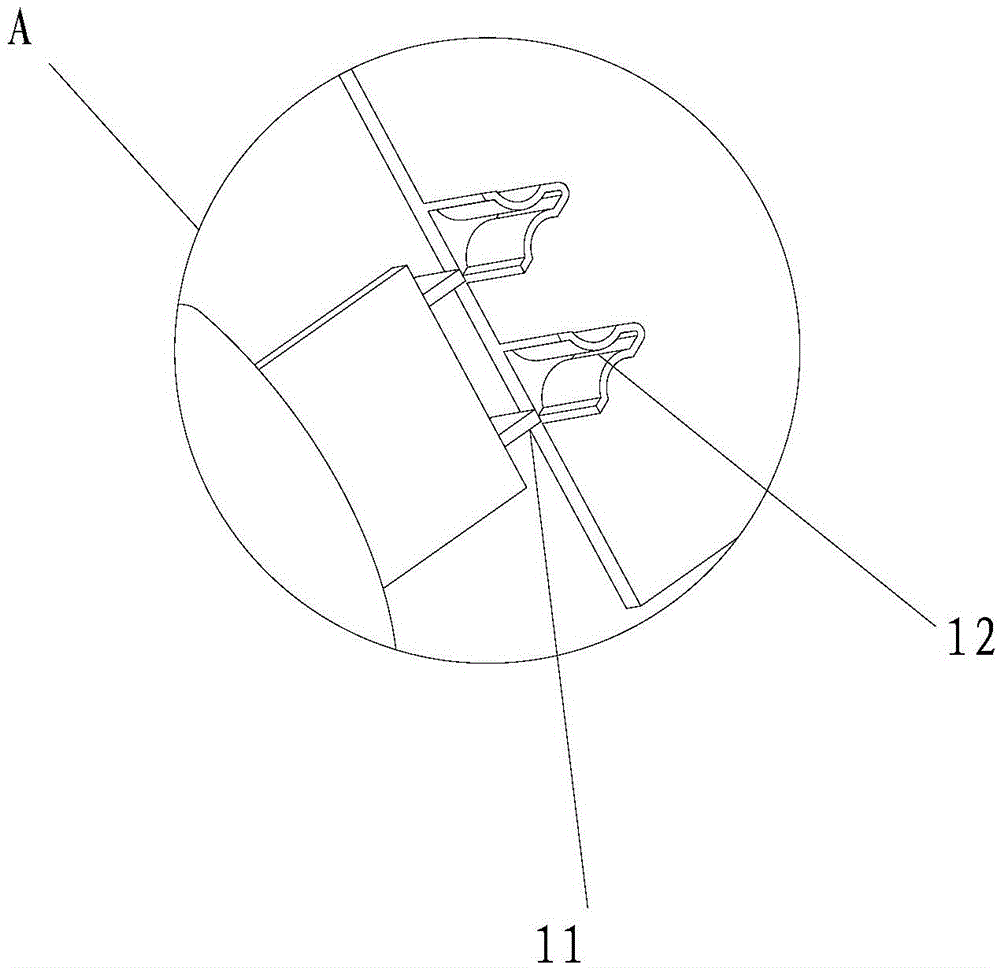

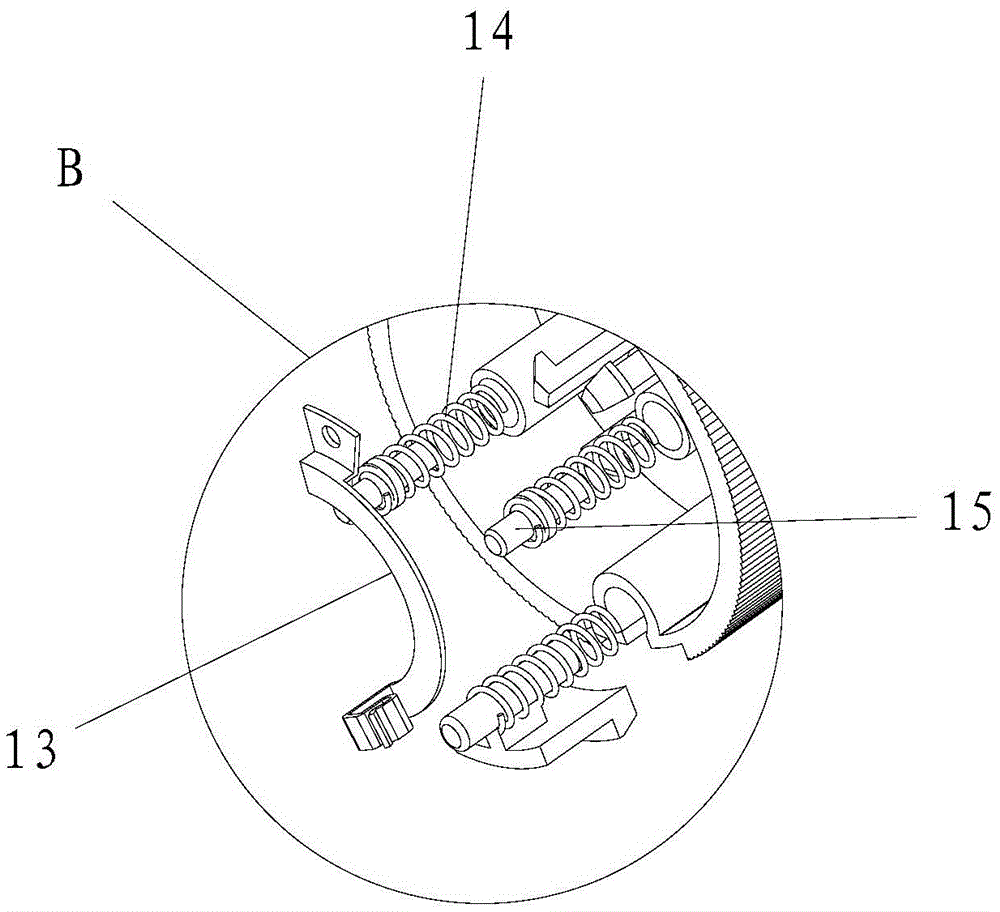

led fluorescent lamp with swivel head

ActiveCN104279446BRealize mechanical automation productionReliable electrical connectionLighting support devicesElongate light sourcesElectricityEngineering

The invention discloses an LED fluorescent lamp with a rotary lamp cap. The LED fluorescent lamp comprises a lamp cap component, a power supply plug component, a driving power supply component, an LED lamp panel component and a diffusion cover. The lamp cap component comprises the lamp cap, a rotary fixing pin, a first compression spring and a rotary power connection pin, the inner side of the end of the lamp cap is provided with accommodating holes and hook-like bumps, the power supply plug component comprises a power supply plug and an input power connection sheet, the end of the power supply plug is provided with clamping holes and a positioning hole, the clamping holes are located in the center of the end of the power supply plug and fit the hook-like bumps to enable the lamp cap to be rotationally connected with the power supply plug, and the positioning hole fits the rotary fixing pin. The lamp cap is rotationally connected with the power plug, the light emitting direction of a lamp tube can be adjusted by rotation of the lamp cap, meanwhile the lamp cap component and the power supply plug are fitted compactly, electrical performance is stable, and automatic assembling of the whole LED fluorescent lamp can be realized.

Owner:深圳市前海洲明投资管理有限公司

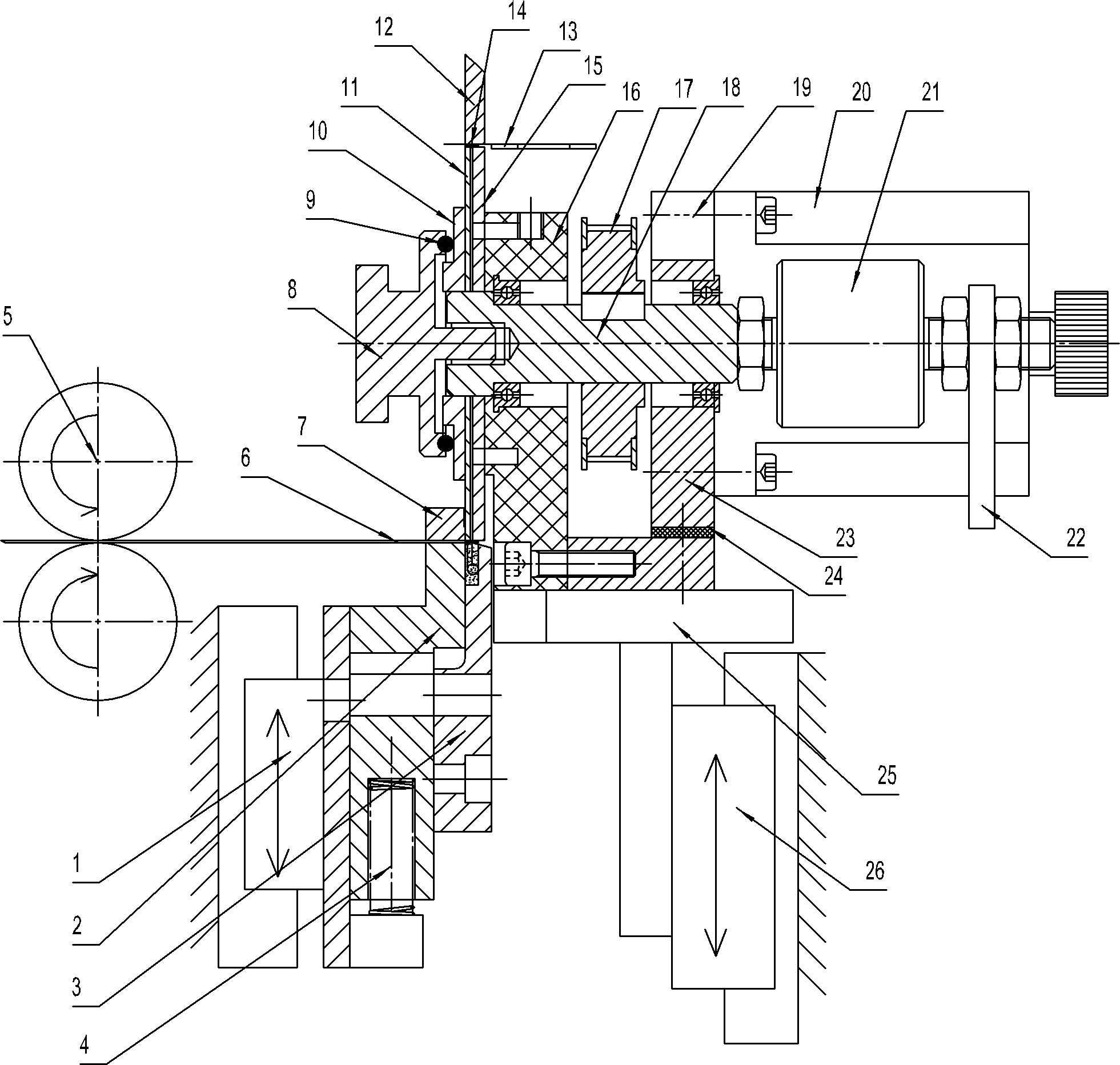

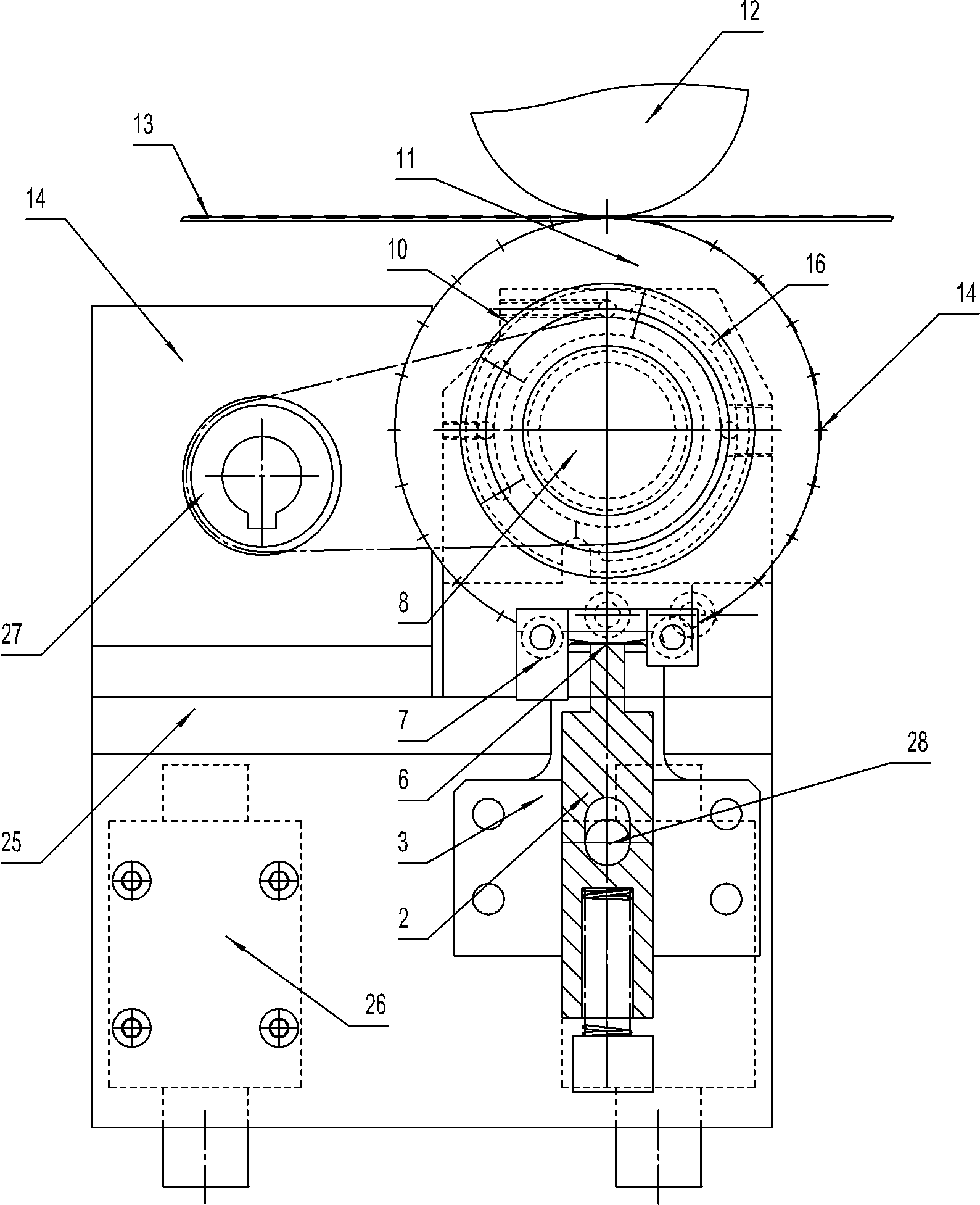

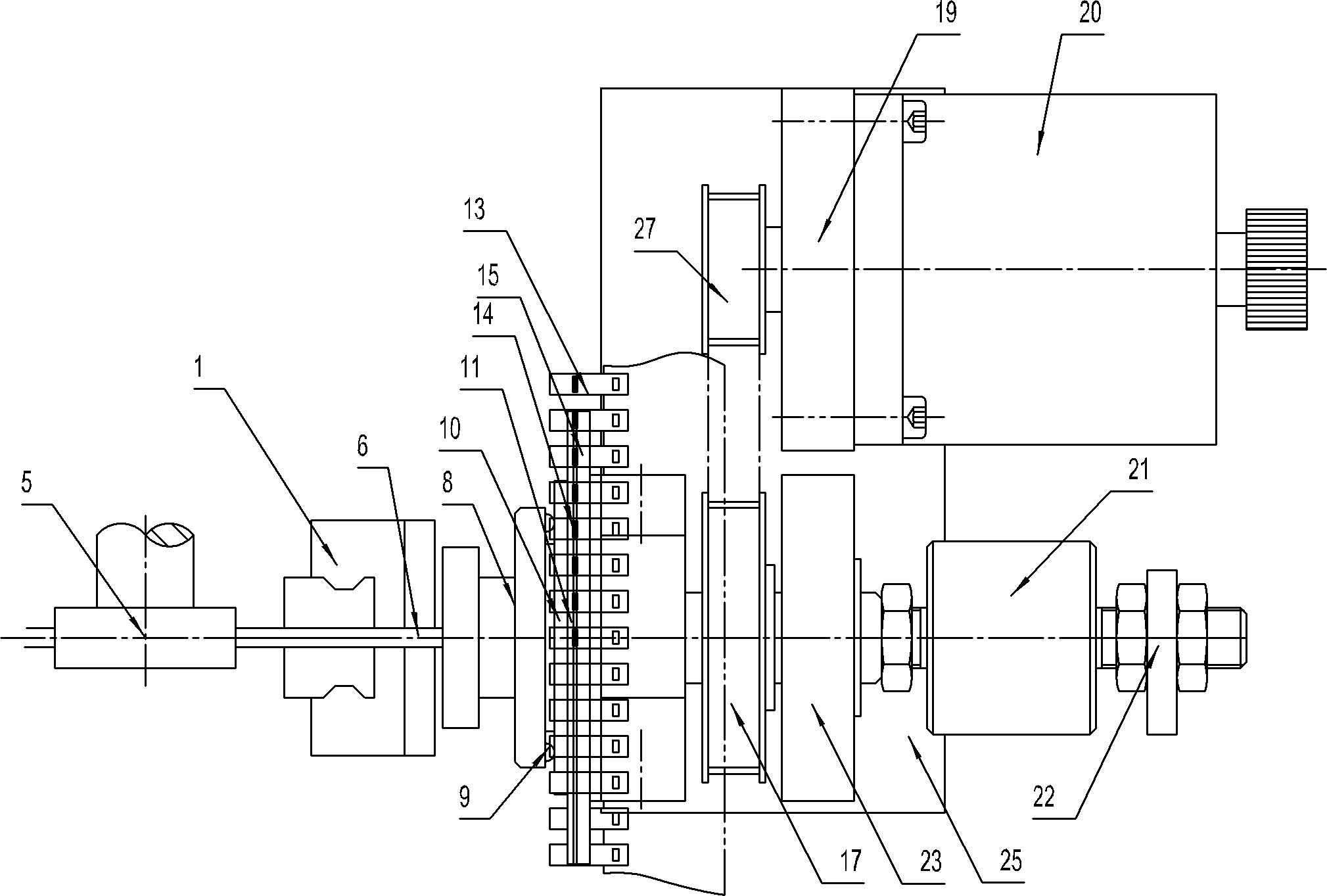

Sheet-type anode gasket welding wheel mechanism of solid aluminium capacitor

InactiveCN102509652BIngenious structureReasonable structureCapacitor manufactureEngineeringCapacitor

The invention relates to a sheet-type anode gasket welding wheel mechanism of a solid aluminium capacitor. According to the technical scheme, the sheet-type anode gasket welding wheel mechanism of the solid aluminium capacitor is characterized by comprising a gasket cutting mechanism and a gasket conveying welding mechanism, wherein the gasket cutting mechanism is used for cutting gasket strips conveyed by conveying wheels into gaskets in blocks, and the gasket conveying welding mechanism is used for conveying the cut gaskets to the welding position and welding the gaskets on aluminium sheetsof the capacitor. The sheet-type anode gasket welding wheel mechanism of the solid aluminium capacitor is ingenious and reasonable in structure, can accurately overlay and weld the capacitor aluminium sheets and tiny anode gaskets according to relative size position requirements, and remarkably improves product welding quality.

Owner:WUXI WANHONG ELECTRONICS MACHINERY

Bottle-making machine and production process for making extra-large glass bottles

ActiveCN104108856BRealize mechanical automation productionIncrease productionBlowing machine gearingsPress and blow machinesVertical planeBottle

The bottle-making machine and production process for making extra-large glass bottles belong to the field of bottle-making machine equipment, including a frame and a preliminary mold forming mechanism, a forming mold forming mechanism and a turning mechanism all installed on the frame; the preliminary mold forming The mechanism includes a punching device, a prototype and a parallel switch mechanism; the punching device is installed on the frame, and the parallel switch mechanism includes a horizontal guide shaft installed on the frame, a clamp arm set on the horizontal guide shaft, and a vertical set on the machine. The first spline shaft, the first rocker arm, the first connecting rod and the first switch cylinder on both sides of the frame; one end of the first connecting rod is hinged with the pincer arm, and the other end is hinged with the first rocker arm, and the first rocker arm passes through The first spline shaft is connected with the first switch cylinder, and the preliminary mold is installed on the tong arm. The beneficial effect of the invention is that: the manual production of extra-large glass bottles is replaced by mechanized automatic production, which increases the output and improves the product quality.

Owner:SHANDONG JIAFENG GLASS MACHINERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com