All-electric bottle making machine

An electric bottle making machine technology, which is applied to the transmission machinery dedicated to glass blowing machines, glass blowing, manufacturing tools, etc., can solve the problems of insufficient product range, unstable mechanism action, and poor air pressure stability, etc. , to achieve the effect of automatic mechanical production, fast action and accurate action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0036] This specific embodiment is only an explanation of the present invention, and it is not a limitation of the present invention. Those skilled in the art can make modifications to this embodiment without creative contribution as required after reading this specification, but as long as they are within the rights of the present invention All claims are protected by patent law.

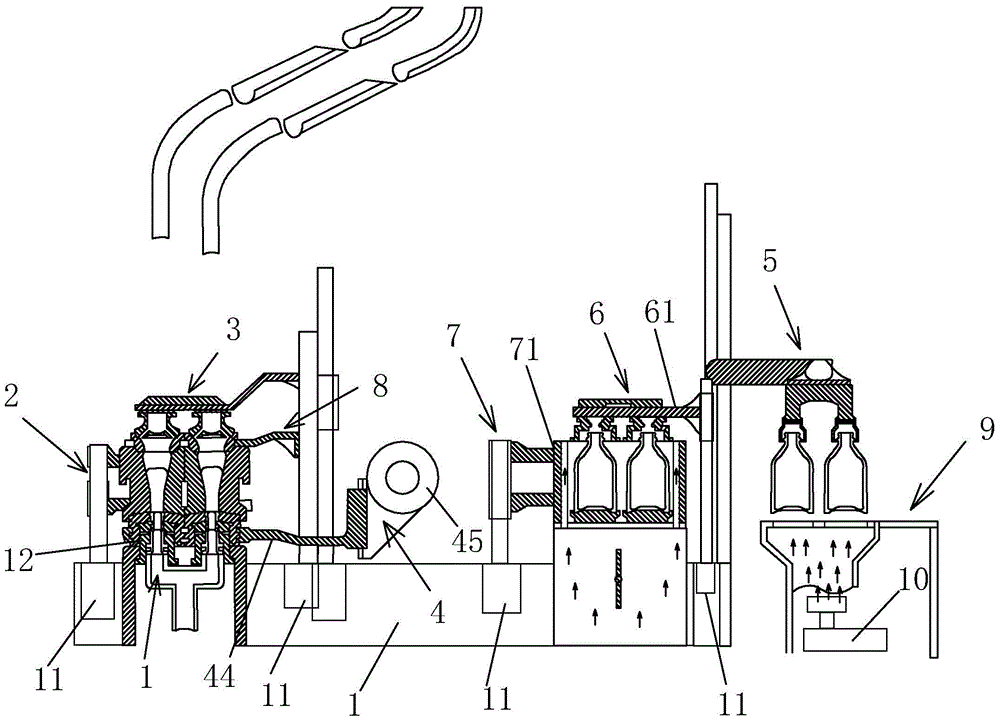

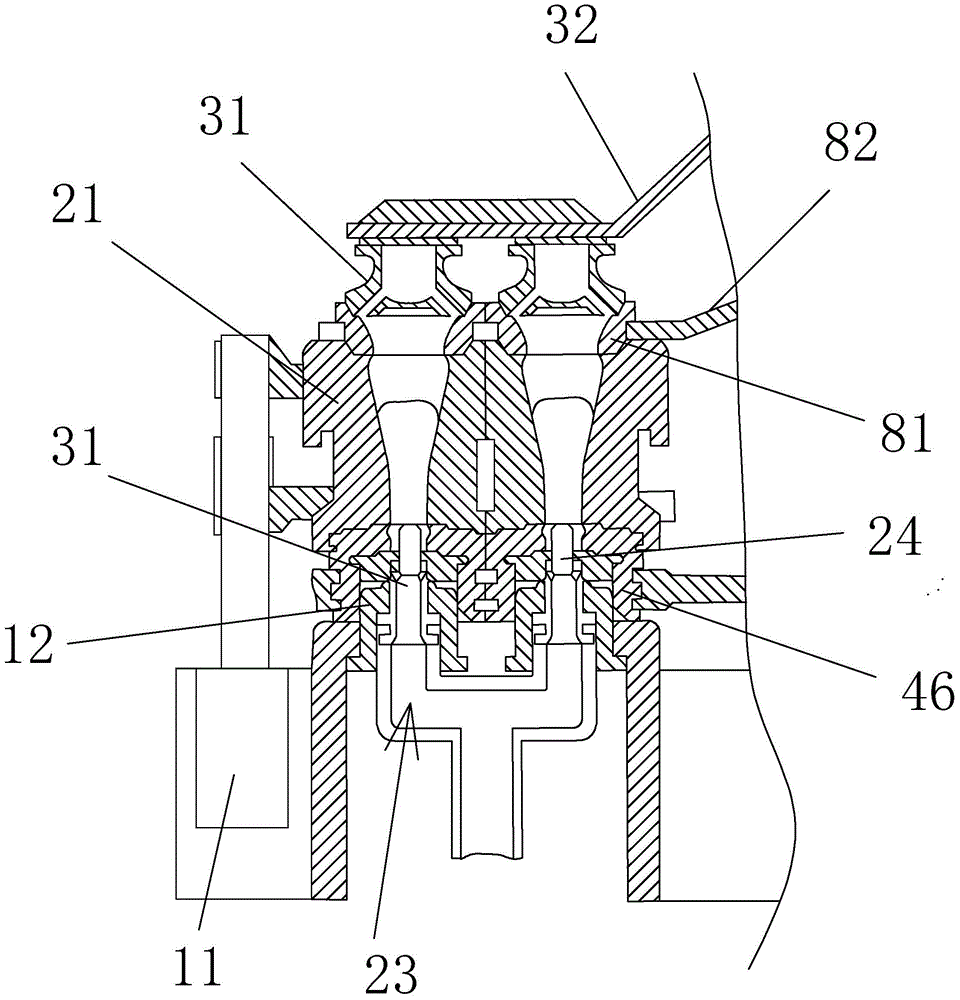

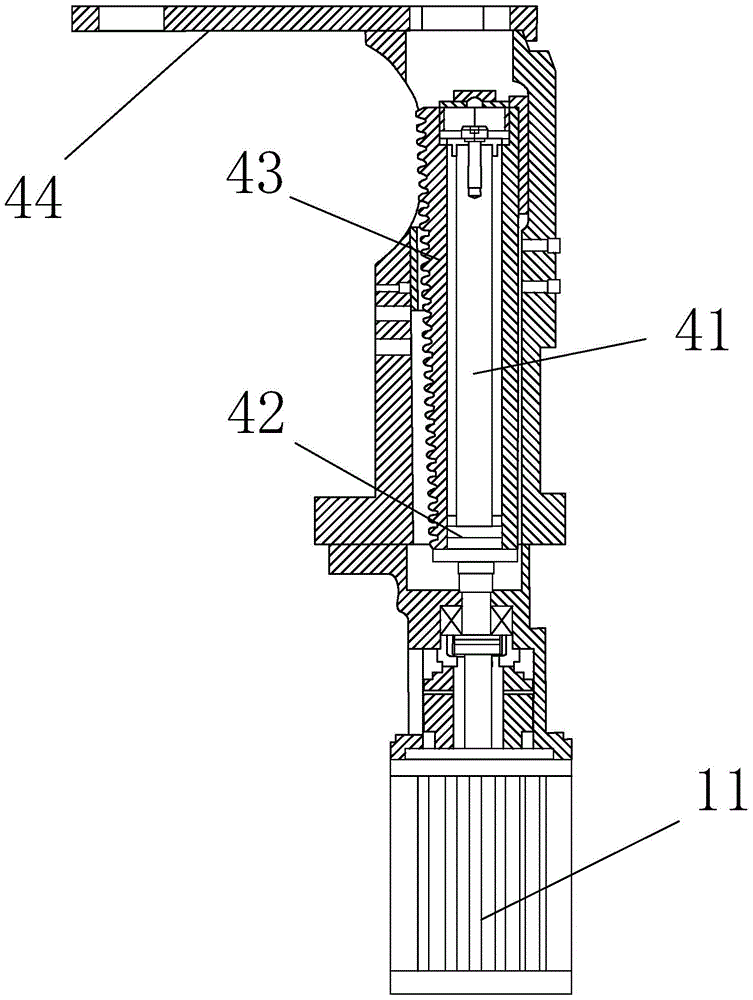

[0037] See figure 1 , an all-electric bottle making machine, including a frame 1 and a preliminary mold forming mechanism 2, an air puffing mechanism 3, a funnel mechanism 8, a turning mechanism 4, a pincer moving mechanism 5 and a positive blowing mechanism installed on the frame 1 6 of the forming die forming mechanism 7; the turning mechanism 4 is located between the initial model forming mechanism 2 and the forming die forming mechanism 7. According to the front and rear seque...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com