Mechanical forming process and equipment of paper pad for packaging box

A pad and paper-based technology, applied in the field of mechanized molding process and equipment, to reduce costs, improve efficiency, improve product quality, and avoid environmental pollution problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

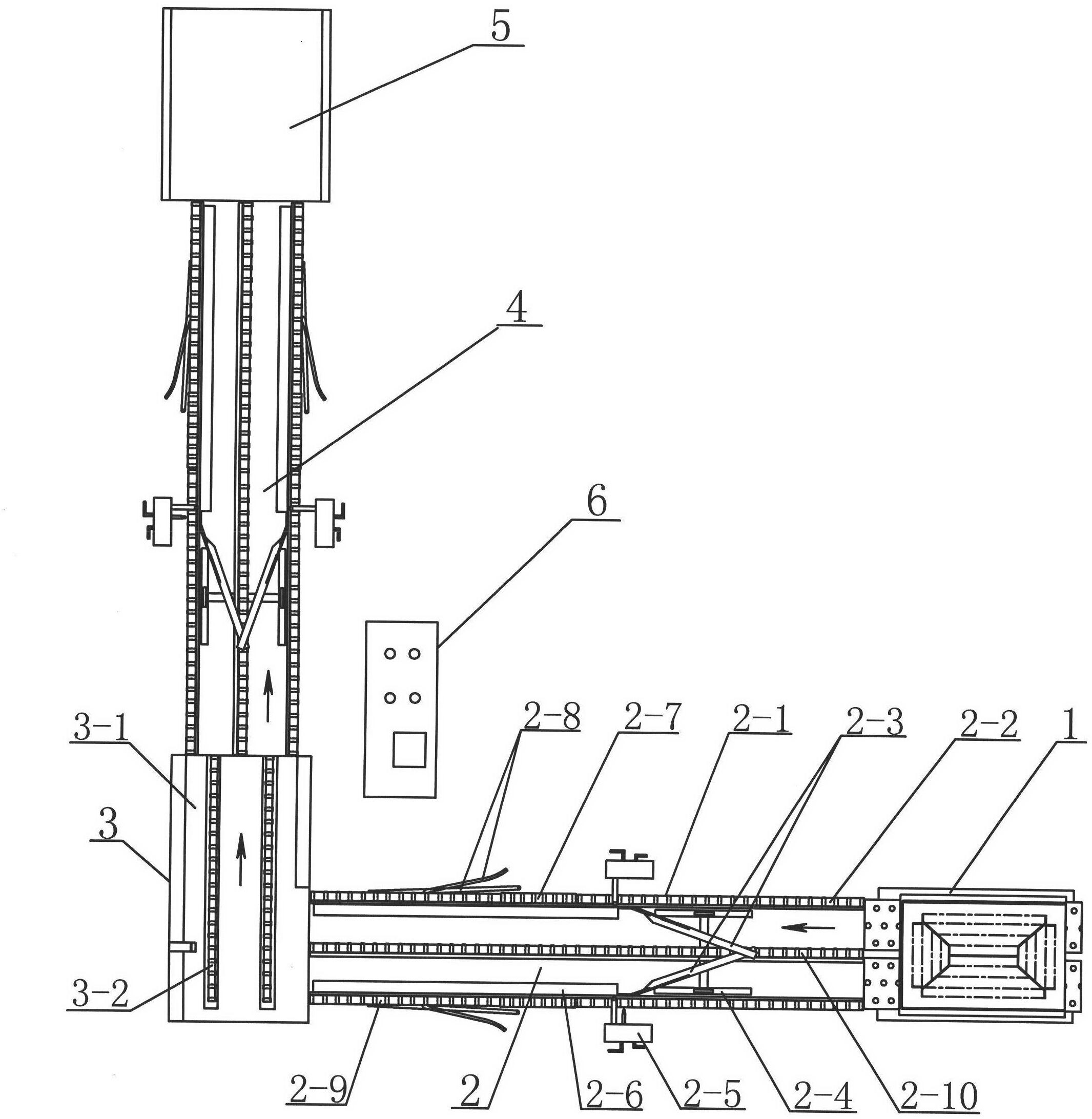

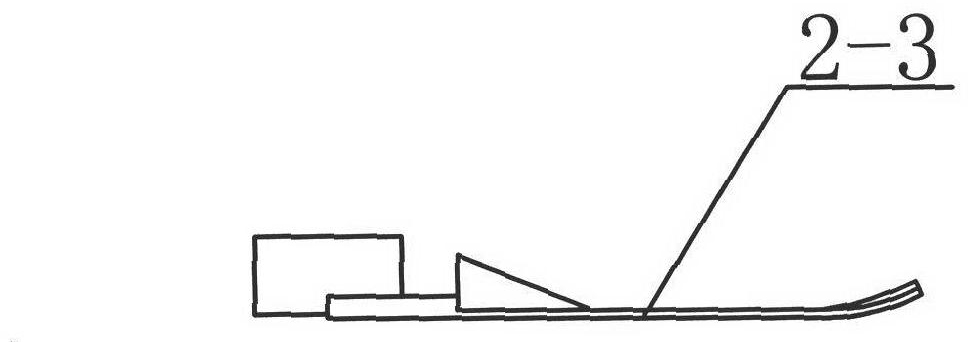

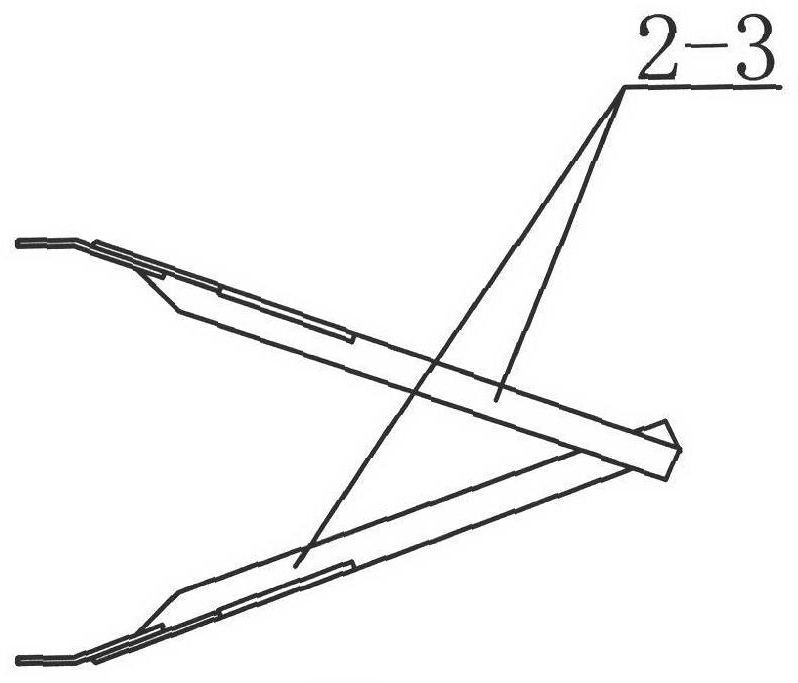

[0021] A paper liner forming machine for packaging boxes, such as figure 1 As shown, it includes a cardboard step-by-step conveying mechanism 1, a longitudinal folding and forming mechanism 2, a transfer platform 3, a horizontal folding and forming mechanism 4, a finished product receiving platform 5, a power part and a console 6, and the cardboard is stepped and conveyed The mechanism 1 is docked with the beginning of the longitudinal folding and forming mechanism 2, the end of the longitudinal folding and forming mechanism 2 forms a right angle docking with the beginning of the horizontal folding and forming mechanism 4 through the transfer platform 3, and the finished product receiving platform 5 is connected to the horizontal folding and forming mechanism 4 The ends of the butt joints; the longitudinal folding forming mechanism 2 includes a trough frame 2-1, and the two side walls of the trough frame 2-1 are respectively provided with a roller type conveying pressure belt 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com