Material clamping mechanism of automatic charging device

An automatic feeding and retrieving mechanism technology, which is applied to the surface coating liquid device, conveyor objects, transportation and packaging, etc., can solve the problems of low production efficiency of automatic assembly line, dense processing equipment placement, high labor intensity of workers, etc. problems, to achieve the effect of realizing mechanical automation production, ensuring automatic feeding, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

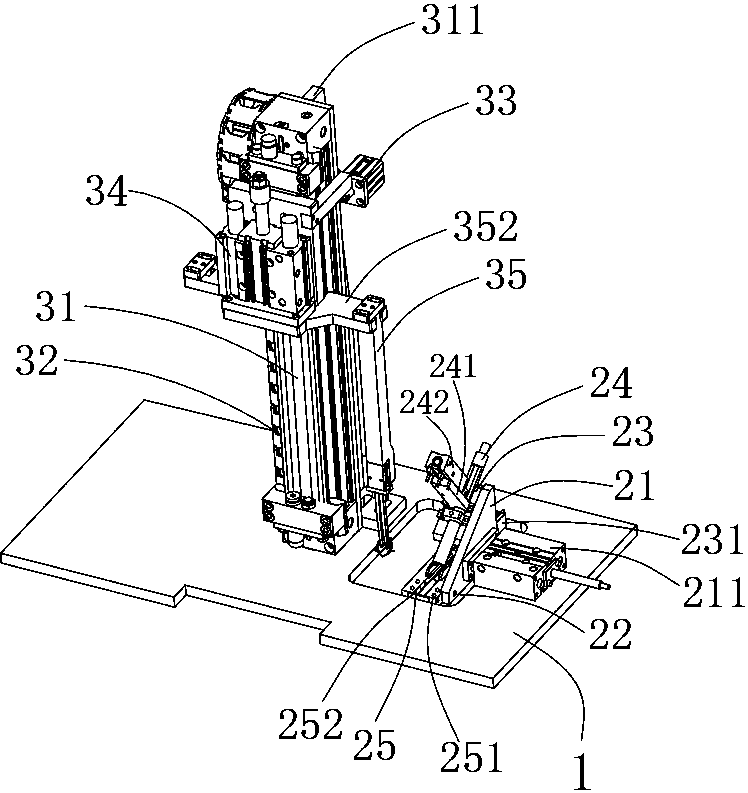

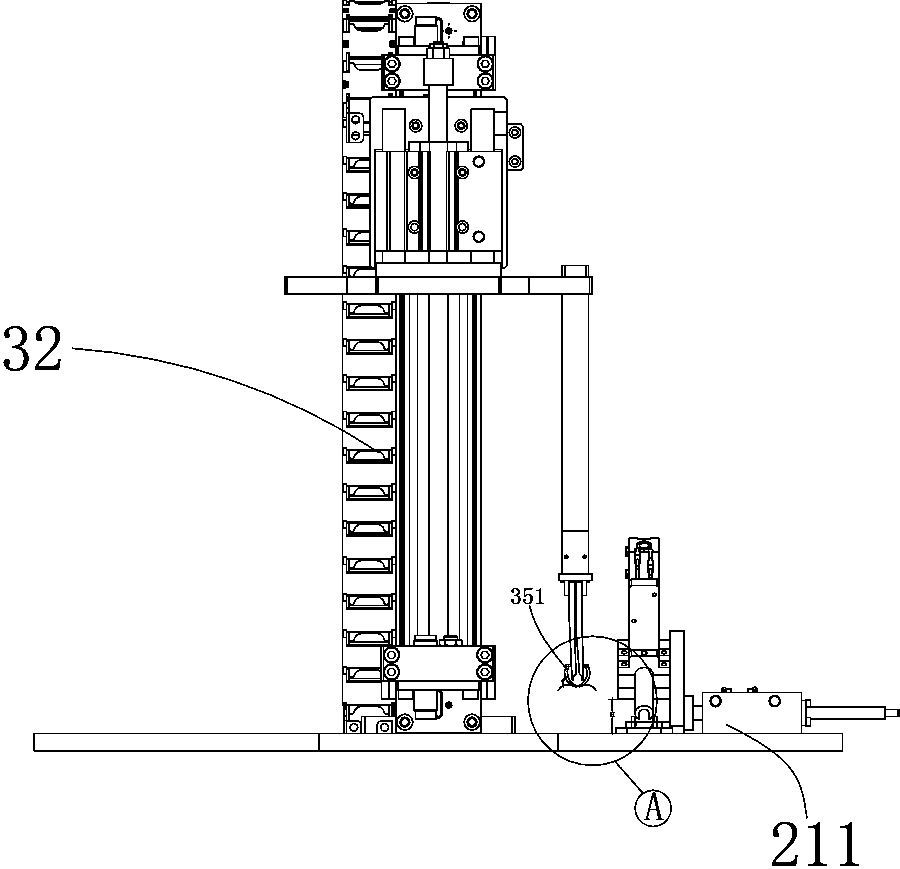

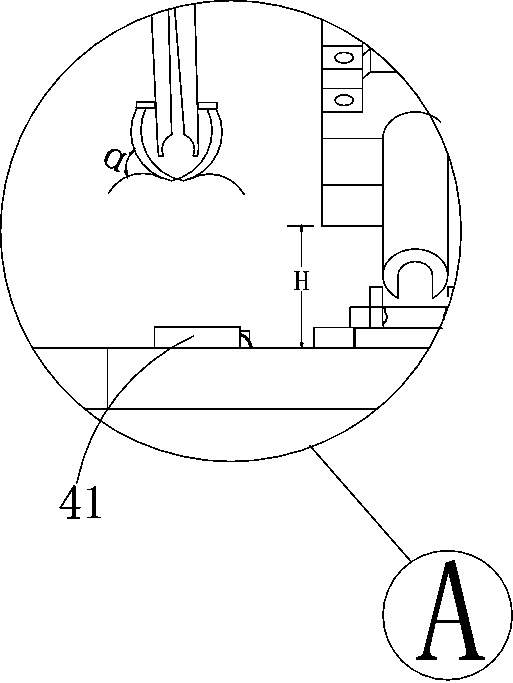

[0014] see Figure 1 to Figure 3 , a clamping mechanism of an automatic feeding device, including a workbench 1, on which a reclaiming mechanism, an air blowing mechanism and a feeding mechanism arranged on one side of the reclaiming mechanism are arranged, the feeding mechanism It includes a cylinder vertical plate 21 arranged perpendicular to the workbench 1, and a signal switch 22 is arranged on the cylinder vertical plate 21. There is a gap H between the platforms 1, the aisle 24 fixed by the pressing mechanism 241 and with the blocking mechanism 242 is arranged on the inclined plate 23, and the receiving slot 25 with the symmetrical air hole 251 is correspondingly provided directly below the end of the aisle 24, The workpiece pushing mechanism 231 disposed behind the inclined plate 23 can pass through the gap between the inclined plate 23 and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com