Single-groove inflation stirring type flotation machine

A technology of inflatable stirring and flotation machines, which is applied in the field of mining machinery and can solve problems such as inability to smelt, unreasonable economics, and great technical difficulties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

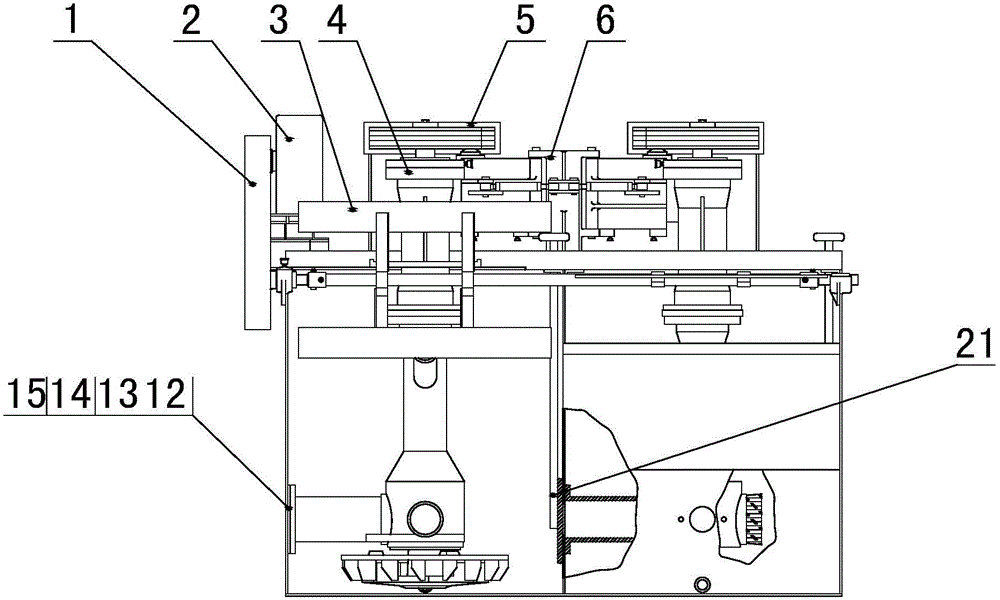

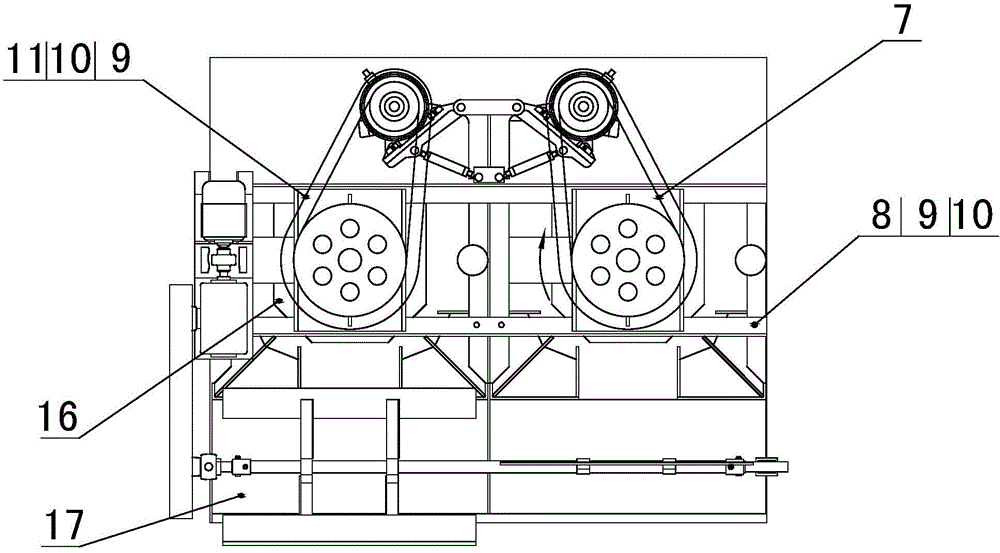

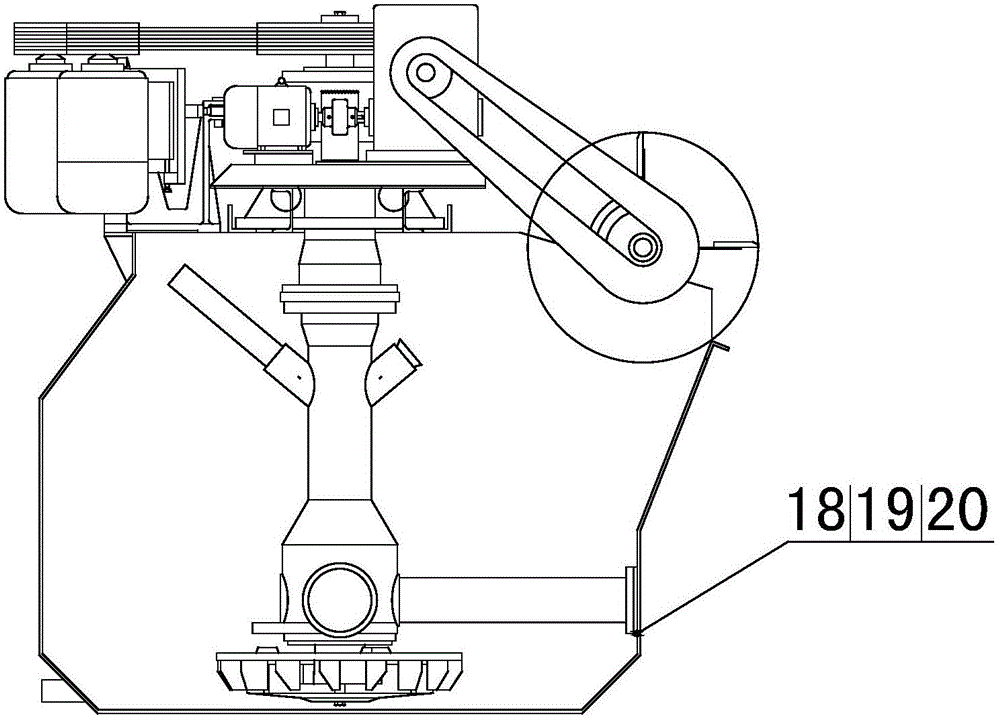

[0021] The present invention will be further described below in conjunction with accompanying drawing:

[0022] A single tank inflatable stirring type flotation machine, as attached Figure 1-3 As shown, it is mainly composed of a foam scraper transmission device 2, a head foam scraper 3, a main shaft mechanism 4, a transmission device 6 and a tank body 17. The vertical shafts are connected, and the stirring device is arranged in the inside of the tank body 17 through a bolt 8, a nut 9 and a flat washer 10. The stirring device is composed of an impeller, a water wheel cover plate, a slurry pipe 12, a screw rod, and a vertical shaft arranged on the vertical shaft. Composed of guide vanes and flow stabilizers; the upper part of the vertical axis is provided with an air intake pipe, and the lower section is provided with a slurry pipe 12 and a medium mine pipe 18 through rubber pads 13, bolts 3 14, nuts 3 15, bolts 4 19 and nuts 4 20. A water wheel cover plate is arranged under ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com