Overturning and wire feeding device and method for waste lead-acid batteries

A lead-acid battery and battery technology, which is applied in the field of waste materials recycling, can solve the problems of increasing the difficulty and cost of recycling, the difficulty of recycling, and affecting the purity of recycled products, so as to achieve the realization of mechanical automation production and avoid harm to the environment and workers' health , The effect of solving the problem of going online and flipping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

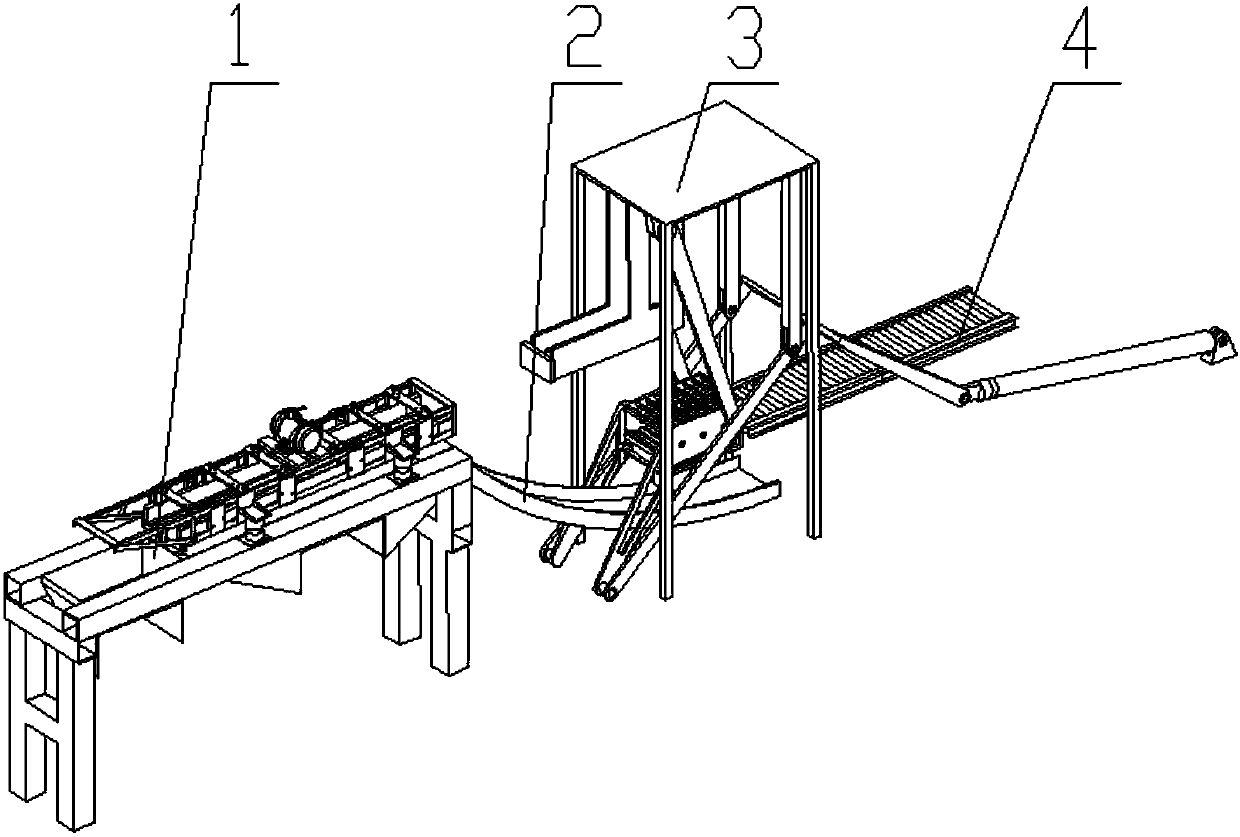

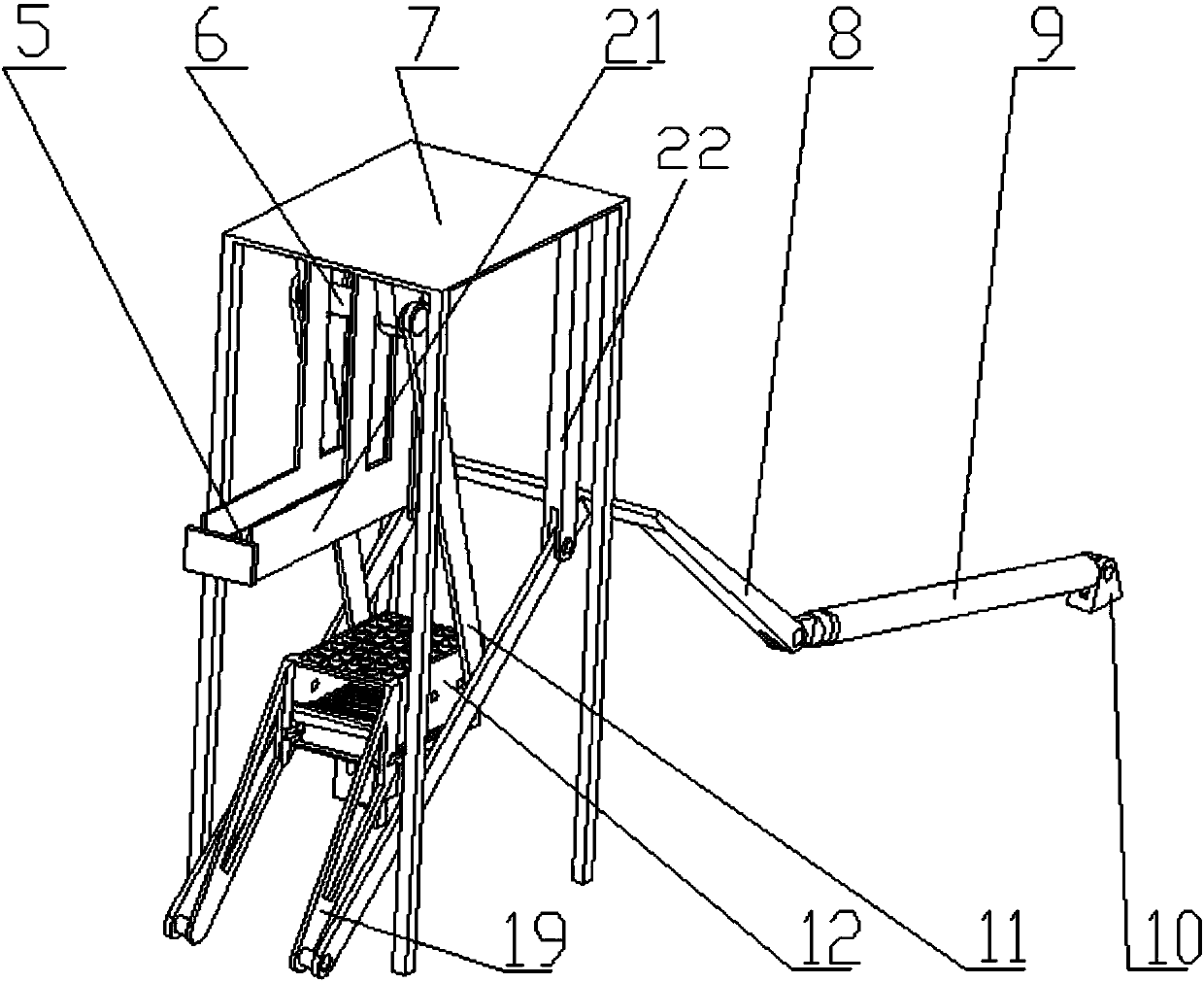

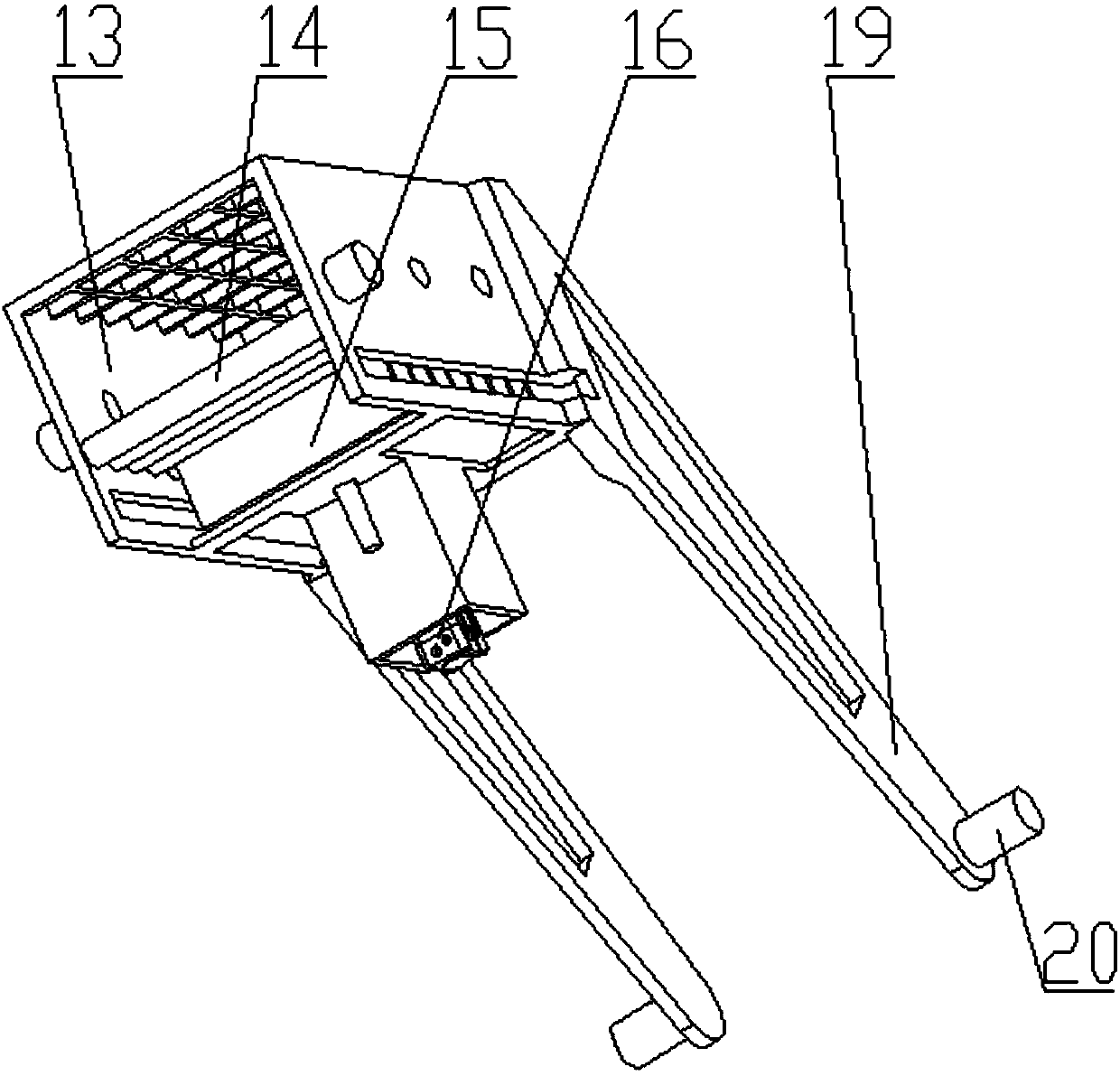

[0035] Attached below Figure 1-11 , introduce the technical solution of the present invention in detail.

[0036] Such as Figure 2-8 Shown is the waste lead-acid battery turnover and on-line device 3 for processing the cut waste lead-acid batteries according to the present invention, and its components mainly include: a turnover frame 7, a battery clamping mechanism 12, and a turning power mechanism , pushing mechanism; the battery clamping mechanism 12, the turning power mechanism, and the pushing mechanism are arranged under the turning frame 7, and the battery clamping mechanism 12 is connected with the turning power mechanism and realizes the turning action under the action of the turning power mechanism; the battery clamping mechanism 12 initially Positioned below the push mechanism during the state, when the turning power mechanism is turned over to the level corresponding to the push mechanism, the push mechanism will act to push out the waste lead-acid battery clamp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com