Anti-eccentric-wear roller type valve rocker arm combined device

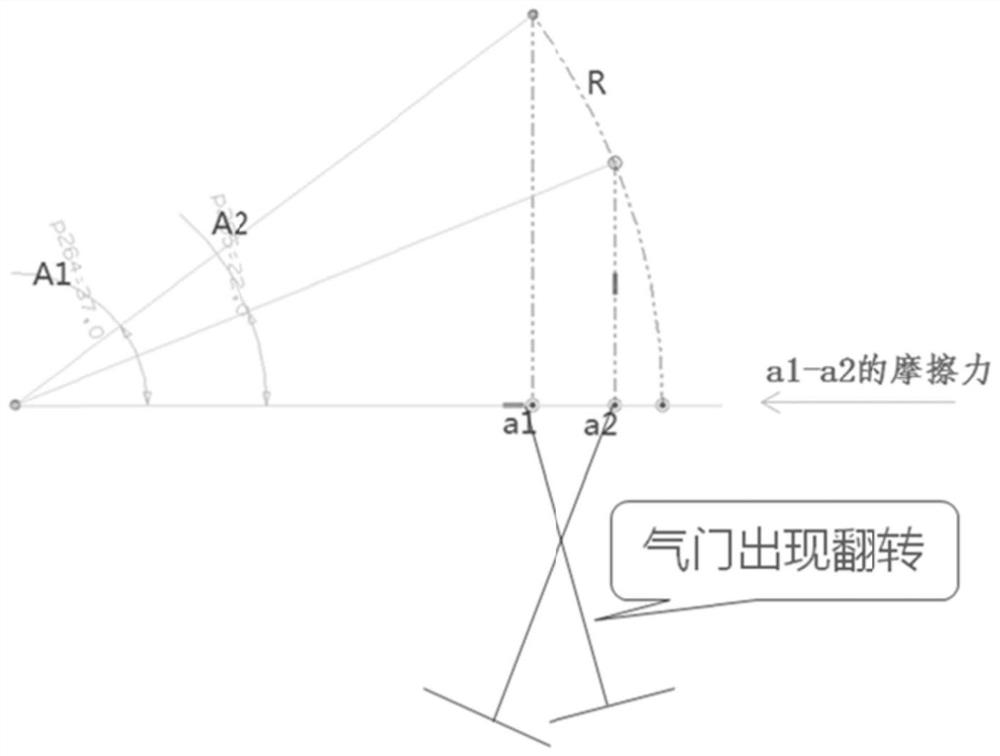

A valve rocker arm and combined device technology, which is applied in the direction of valve devices, engine components, machines/engines, etc., can solve the front and rear partial wear of valves and valve seat rings, non-fixed contact points between rocker arm pressure heads and valve bridges, and valve failure Complete up and down vertical movement and other issues to achieve uniform valve wear and avoid the effect of valve turnover

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, but it should be understood that the protection scope of the present invention is not limited by the specific embodiments.

[0019] Unless expressly stated otherwise, throughout the specification and claims, the term "comprise" or variations thereof such as "includes" or "includes" and the like will be understood to include the stated elements or constituents, and not Other elements or other components are not excluded.

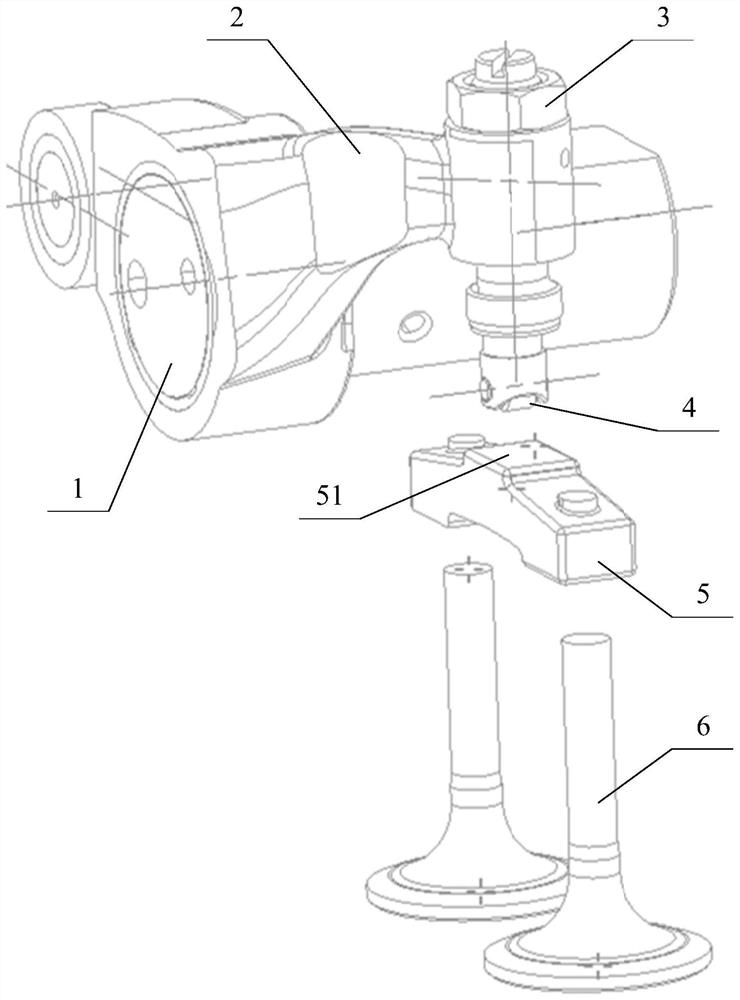

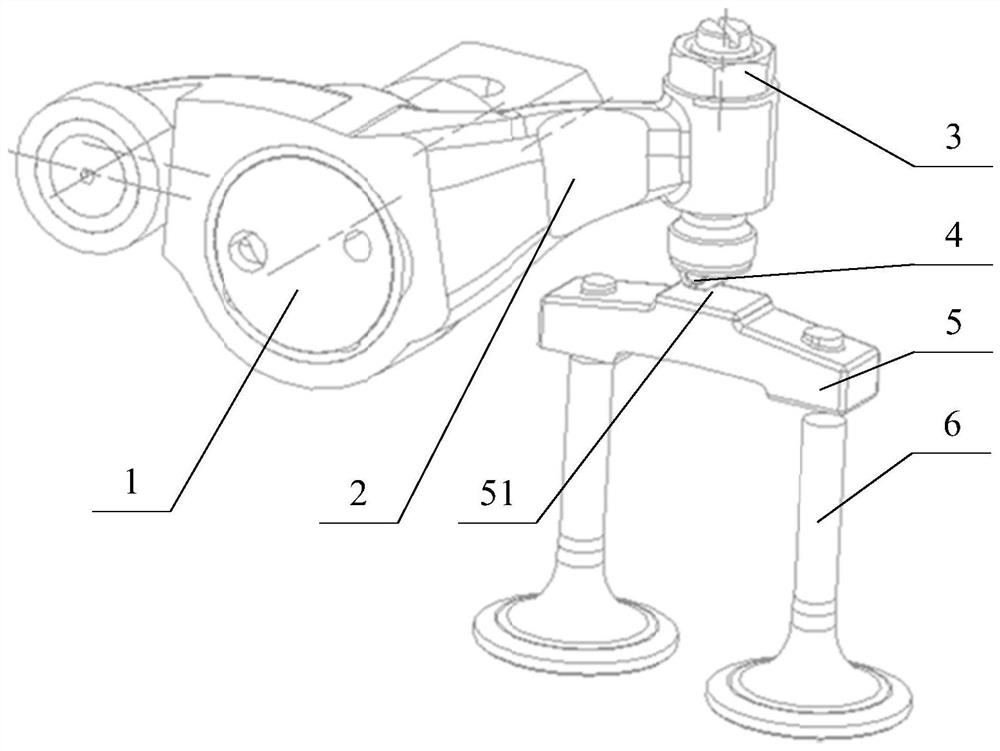

[0020] like Figure 1 to Figure 2 As shown, an anti-eccentric roller valve rocker arm combination device according to a preferred embodiment of the present invention includes a valve rocker shaft 1, a valve rocker arm 2, a valve adjustment screw 3, a roller 4, a valve bridge 5 and a valve 6 .

[0021] see Figure 1 to Figure 2 , in some embodiments, the valve rocker shaft 1 can rotate around the circumference of the valv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com