Dismounting tool and method for dismounting axle of sintering trolley

A technology for sintering trolleys and axles, used in metal processing, manufacturing tools, metal processing equipment, etc., can solve the problems of wasting manpower and machinery costs, failing to meet the requirements of lifting personnel, and high requirements for lifting professional levels. Cost saving, improving repair efficiency, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings; it should be understood that the preferred embodiments are only for illustrating the present invention, rather than limiting the protection scope of the present invention.

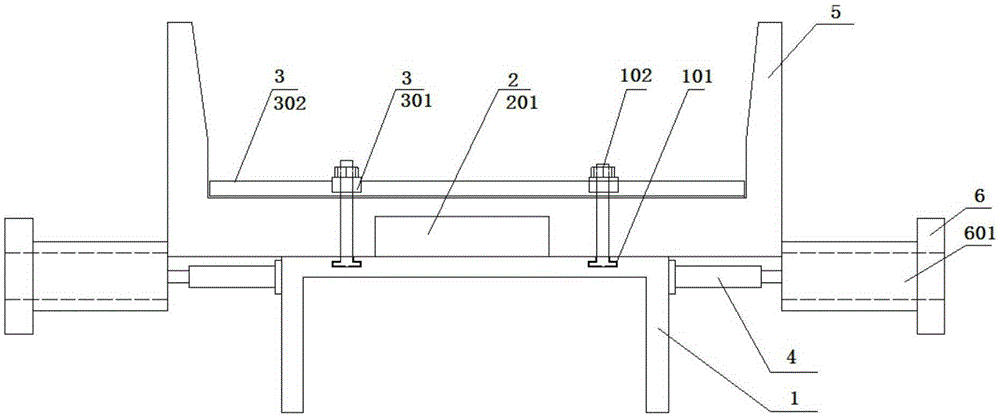

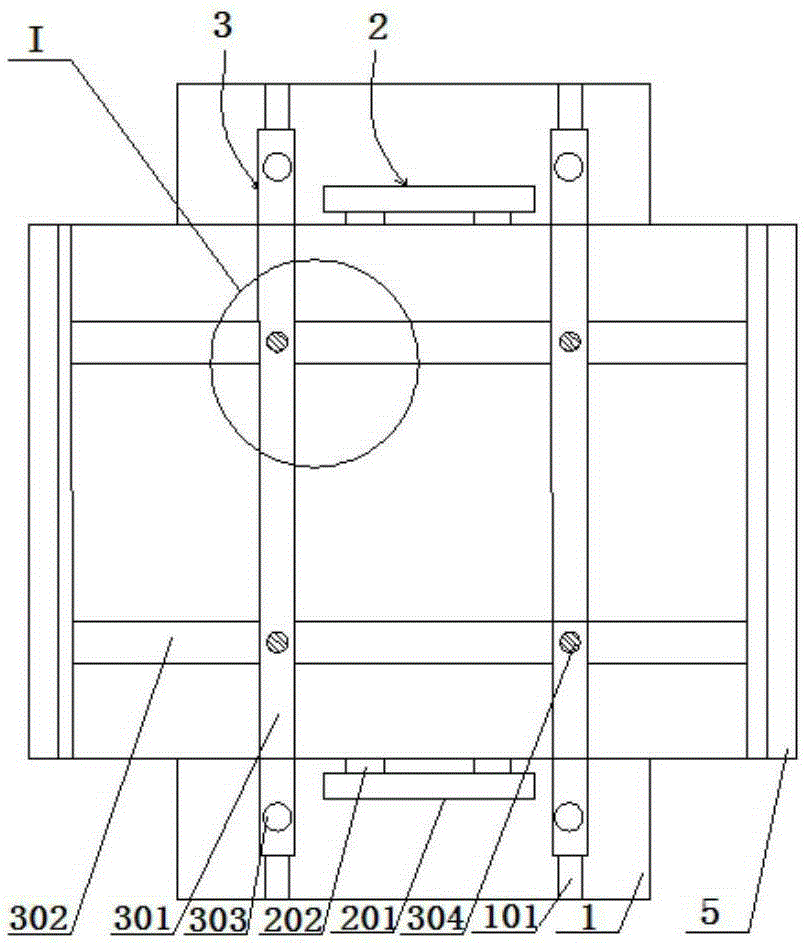

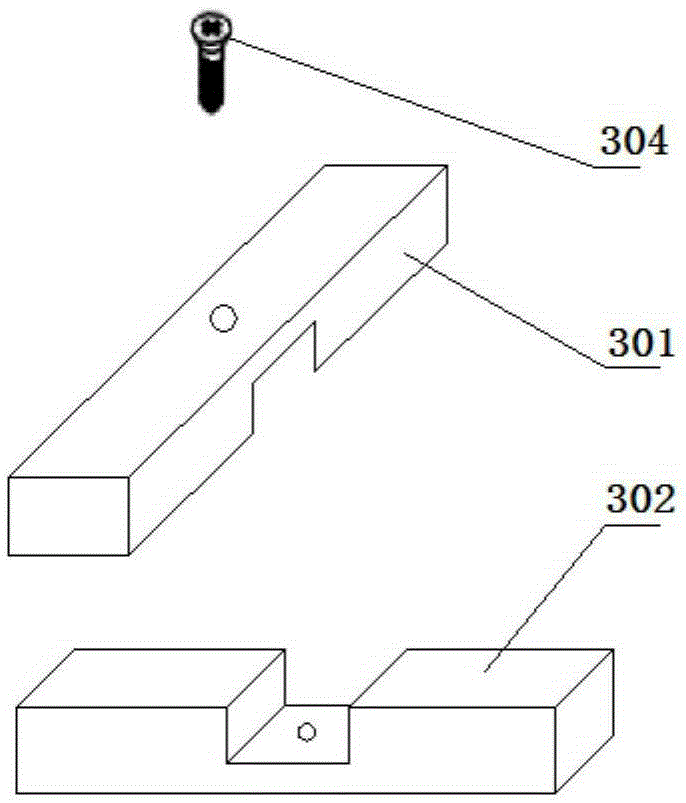

[0028] Such as Figure 1-2 Shown: the present invention is a disassembly and assembly tool for disassembling the wheel axle of the sintering table, including a platform 1 for carrying the trolley 5, and the positioning device 2 that restricts the forward and backward movement of the trolley 5 is arranged on the platform 1 , the clamping device 3 that restricts the left and right and up and down movement of the trolley 5 and the jacking device 4 for removing the axle 601 of the trolley 5 .

[0029] Specifically, first, the trolley 5 is directly placed flat on the platform 1 through the lifting equipment, and the trolley does not need to be turned over during this period,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com