Tandem type turning manipulator of large propeller

A flipping manipulator and serial technology, applied in manipulators, program control manipulators, manufacturing tools, etc., can solve the problems of difficult to guarantee the safety of equipment, low work efficiency and low efficiency of flipping problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

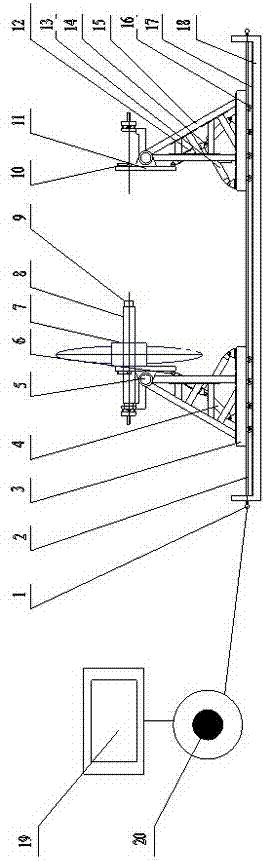

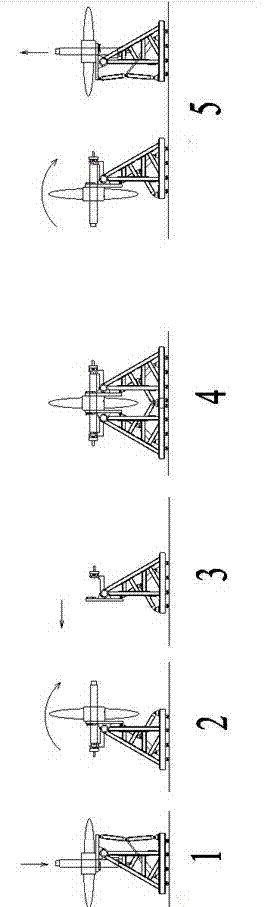

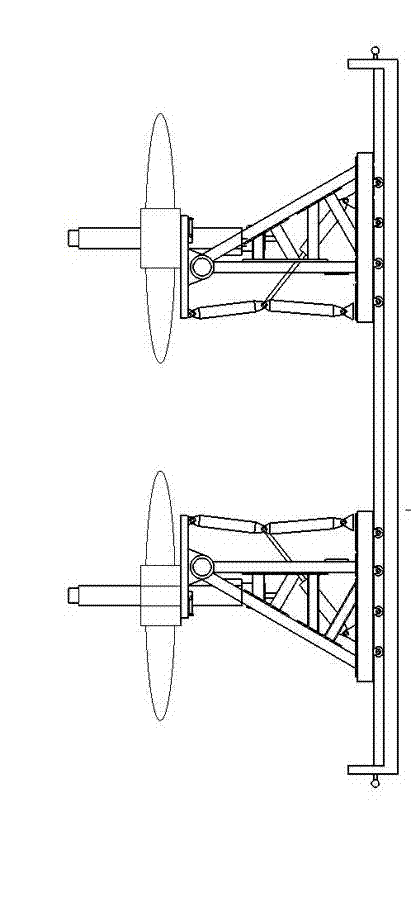

[0019] combine figure 1 , the mobile platform roller 16 and the mobile platform 3 form a rolling trolley that can move laterally along the double rolling guide rails 17, and the trolley pushes the mobile platform to reciprocate under the drive of the mobile drive motor 1 and the screw screw mechanism 2. The mobile platform 3 is used as the installation base of the manipulator, the lower part of the frame 15 is fixedly connected with the upper surface of the mobile platform 3, the lower end of the lower booster rod 13 and the lower end of the turning drive hydraulic cylinder 4 are respectively hinged with the corresponding hinges on the platform, and the upper end is connected with the upper booster The lower end of bar 12 links to each other by booster bar driving hinge 14, and the upper end of booster bar 12 is hinged with the flipping pallet driving hinge 6 that is fixedly connected at one end of flipping pallet 11. The frame that is fixedly connected at the top of the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com