Wire disassembling device of automobile

A technology for automobile dismantling and equipment, applied in the fields of motor vehicle and vehicle scrap recycling, recycling technology, etc., can solve the problems of unclear process of dismantling automobiles, low integration of dismantling equipment, and inability to realize automatic operation, etc. The dismantling process is clearly organized, the labor intensity of workers is reduced, and the incidence of safety accidents is reduced

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

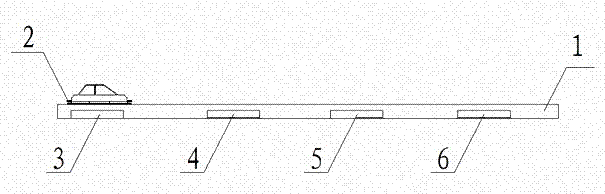

[0023] Such as figure 1 As shown, a kind of automobile dismantling line equipment of the present embodiment includes a conveying device 1 dismantling station and a tray device 2, and the dismantling station is arranged along the conveying device 1, including an engine dismantling station 3, a parts dismantling station Dismantling station 4, waste oil extraction station 5 and hazardous waste dismantling station 6, the pallet device 2 is set on the conveying device 1, and the used cars are disassembled after being set on the pallet, so as to realize barrier-free transportation run, so that the entire dismantling process can be linked smoothly without causing damage to the conveying device 1 .

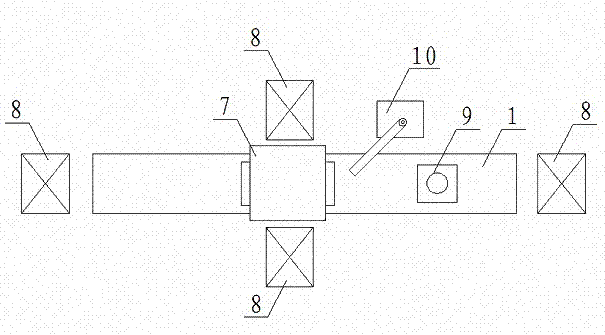

[0024] Such as figure 2 As shown, a turning device 7, a lifting device 8, a rotating device 9, and a transfer device 10 are also included. Lifting device 8 is arranged on the both sides of the head and tail of conveying device 1 and overturning device 7, and lifting device 8 is a hydra...

Embodiment 2

[0032] The rest are the same as in Embodiment 1, the difference is that the lifting device 8 is a pneumatic lifting platform, and compressed air is used as the working medium so that the air is inexhaustible and will not pollute the environment.

[0033] The beneficial effect of adopting this technical solution is: the car to be disassembled can be transported to different dismantling stations, the dismantling process is clear, the automatic production of machinery for dismantling the car is realized, the operation is convenient for workers, and the production efficiency is greatly improved , Reduce the labor intensity of workers, reduce the incidence of safety accidents, while protecting the environment and saving resources.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com