Multifunctional full automatic wire ranging terminal pressing machine

A terminal crimping machine, fully automatic technology, applied in the direction of line/collector parts, electrical components, circuits, etc., can solve the problems of product defect rate, production cost, low production efficiency, etc., to ensure product quality, improve efficiency, The effect of increasing the degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

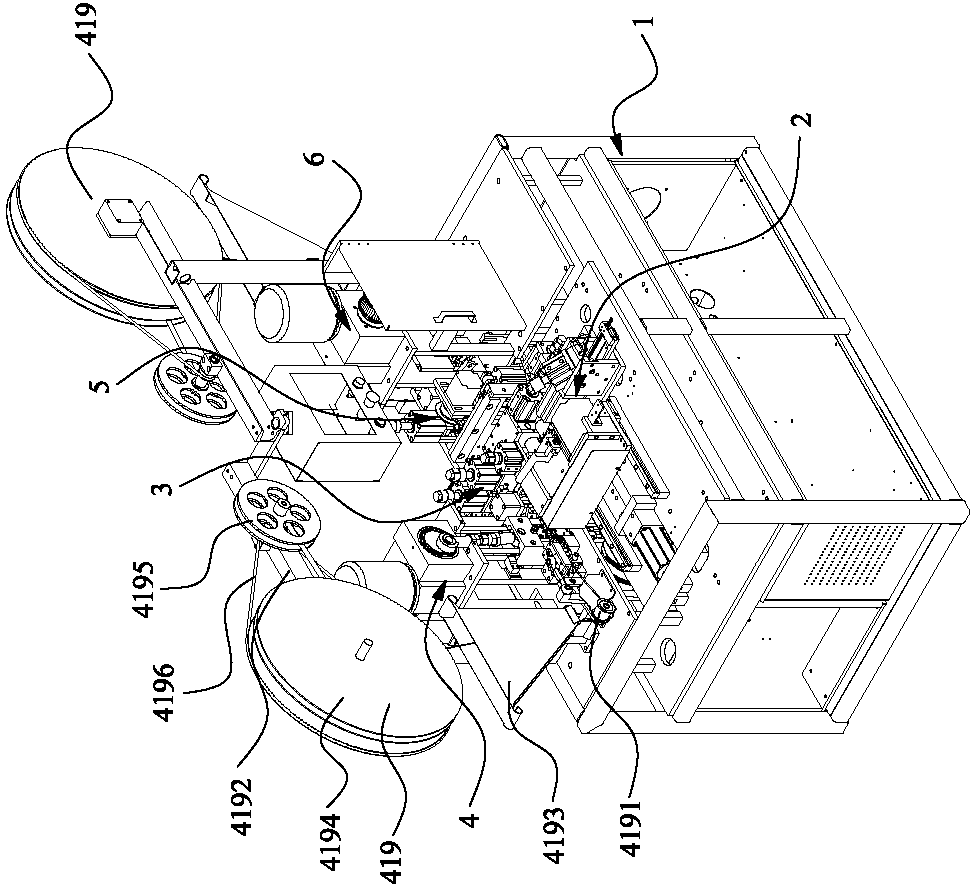

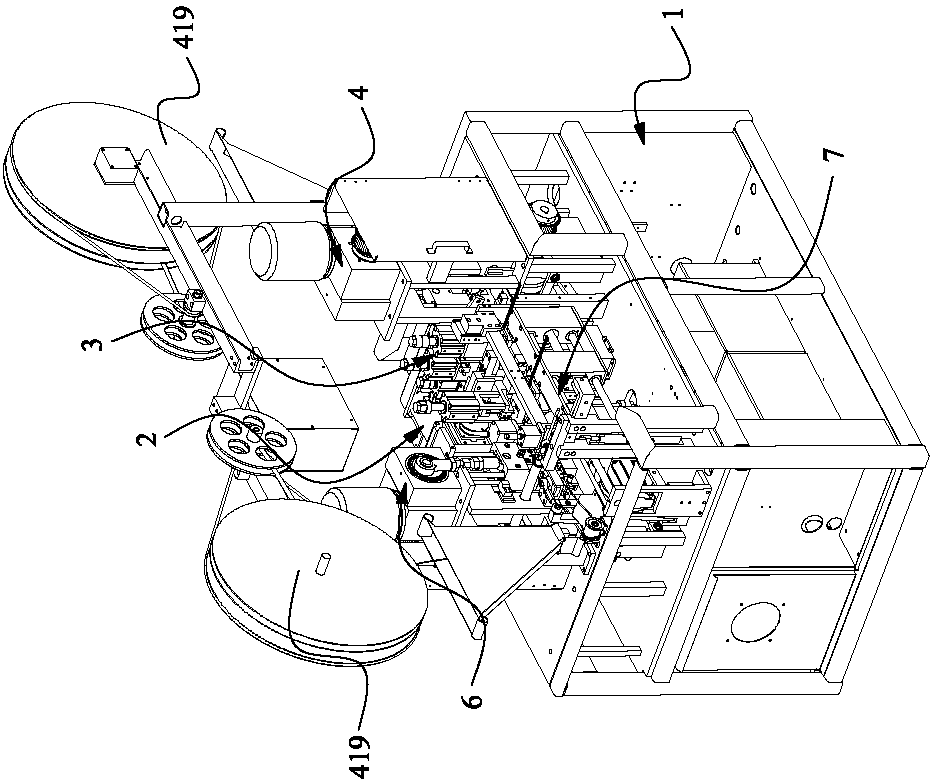

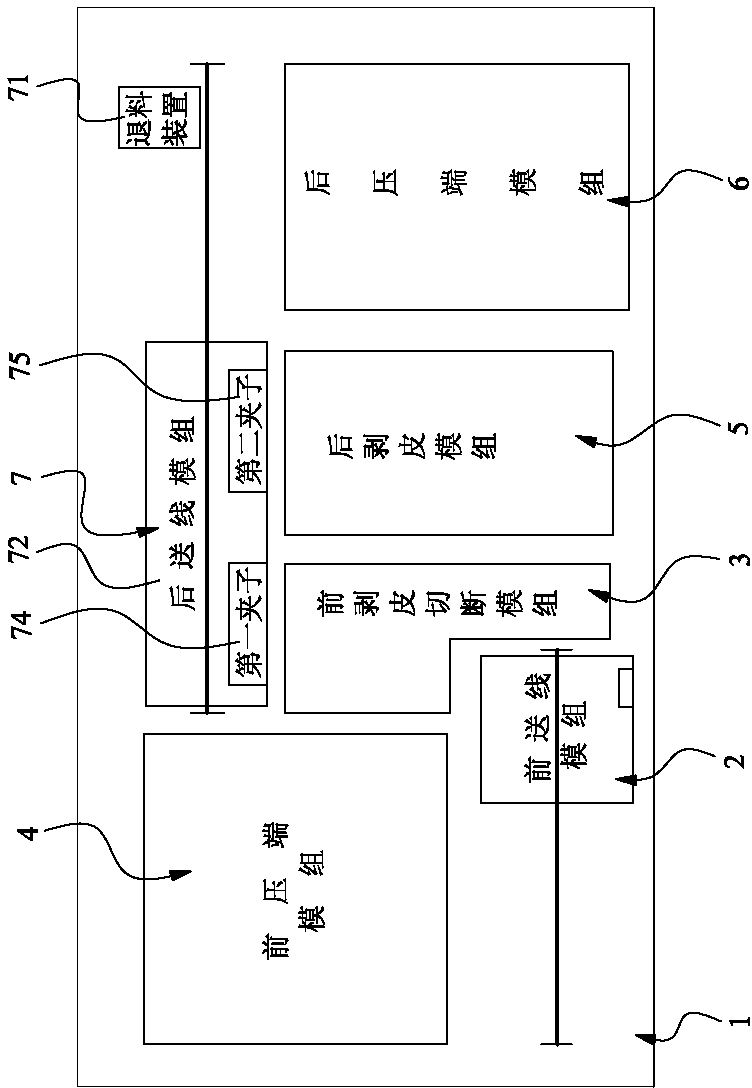

[0038] Please refer to Figure 1 to Figure 20 As shown, it shows the specific structure of the preferred embodiment of the present invention, including a frame 1 and a front wire feeding module 2, a front peeling and cutting module 3, and a front pressing end die set on the frame 1. Group 4, rear peeling module 5, rear crimping module 6 and rear feeding module 7; as image 3 As shown, the front crimping module 4, the front peeling and cutting module 3, the rear peeling module 5 and the rear crimping module 6 are arranged side by side in sequence horizontally, and the front wire feeding module 2 is arranged on the front peeling and cutting module 3 And the front side of the front crimping end module 4, the back feeding wire module 7 is arranged on the rear side of the front peeling and cutting module 3, the back peeling module 5 and the back crimping end module 6.

[0039] Wherein, the wire feeding module 2 is used for conveying the cable 101 and separating the two wires that ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com